In situ controllable synthesis method for hydrotalcite-supported Pd nano crystal catalysts with different morphologies and application of hydrotalcite-supported Pd nano crystal catalysts in catalysis of Heck reaction

A synthetic method, hydrotalcite technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the limitations of exploration, uneven morphology of Pd nanoparticles, etc. problem, to achieve the effect of good dispersion, uniform shape and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

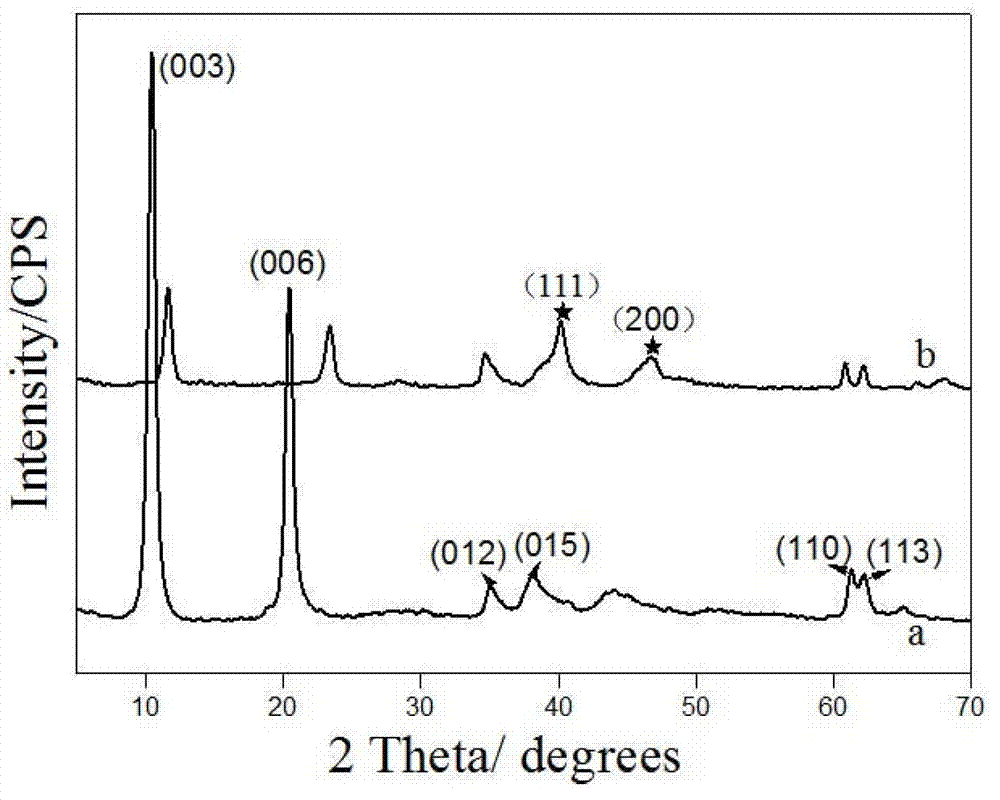

[0020] 1. Prepare nitrate intercalated hydrotalcite by nucleation / crystallization isolation method, the specific method is: weigh 25.64g of Mg(NO 3 ) 2 ·6H 2 O and 18.75g of Al(NO 3 ) 3 9H 2 O dissolved in 80ml of deCO 2 Prepare mixed salt solution A in deionized water, weigh 12.00g NaOH and dissolve in 100mL deCO2 2 Make alkaline solution B in deionized water, add solutions A and B to the fully back-mixed liquid membrane reactor at the same time, the working voltage is 140V, the rotor speed is 5000rpm, back-mix for 2min, and transfer the obtained white slurry to the polytetrafluoroethylene reactor In the process, hydrothermal crystallization at 110°C for 24h, followed by washing three times with deionized water, and drying at 70°C for 12 hours to obtain nitrate intercalated hydrotalcite.

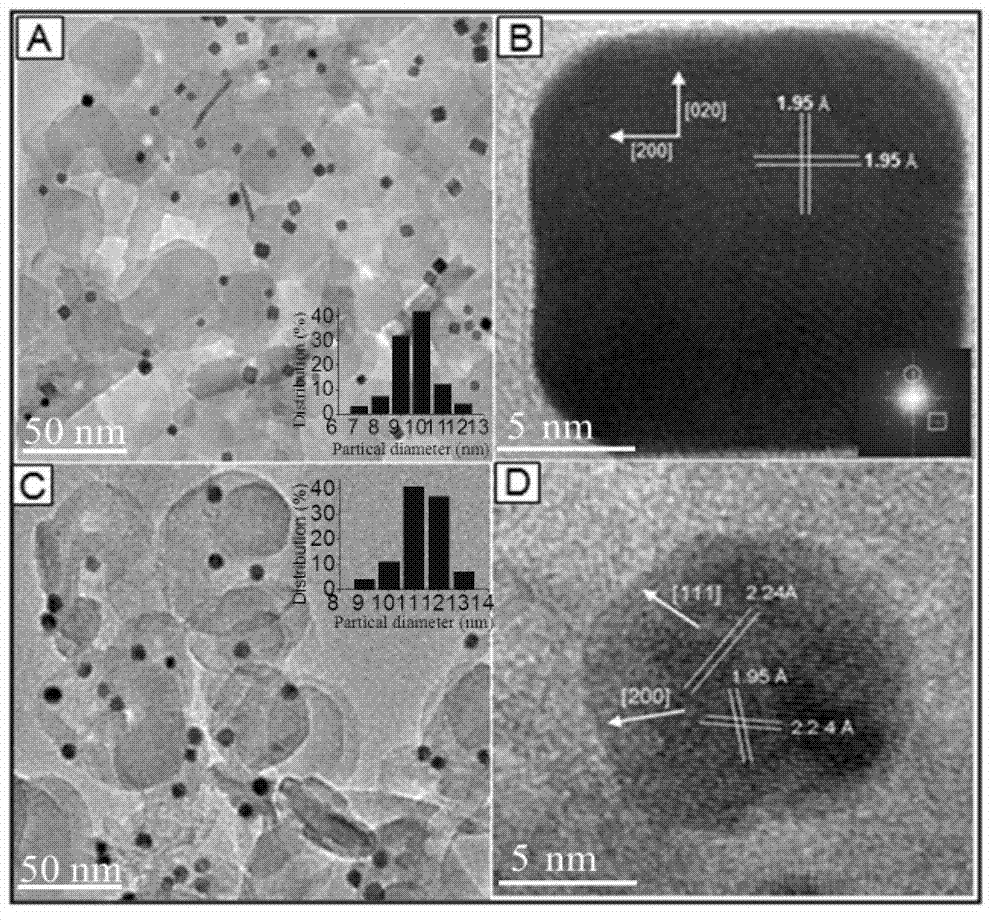

[0021] 2. Intercalate 0.45g of nitrate hydrotalcite with 0.05g of Na 2 PdCl 4, 0.6g of KI, and 0.82g of polyvinylpyrrolidone with a molecular weight of 10,000-20,000 were added to 1...

Embodiment 2

[0025] 1. Same as embodiment 1.

[0026] 2. Intercalate 0.50g of nitrate with 0.06g of Na 2 PdCl 4 0.82g of polyvinylpyrrolidone with a molecular weight of 50,000-60,000 was added to a mixed solution of 16ml of ethylene glycol and 4ml of water and mixed evenly, then stirred and reacted for 5 hours in an oil bath at 90°C, and the obtained product was centrifuged with acetone for 1 Centrifuge twice with a mixed solution of ethanol and deionized water with a volume ratio of 2:1, and dry in vacuum to obtain a Pd nanocrystalline catalyst with a hydrotalcite-supported truncated octahedral shape, which is denoted as Pd-TROCs / LDH, The loading of Pd nanocrystals is 3.12wt%.

[0027] 3. The Pd-TROCs / LDH prepared above was applied to catalyze the Heck coupling reaction. The reaction conditions were: disperse 60 mg of Pd-TROCs / LDH in 15 mL of N,N-dimethylformamide, and then add 1 mmol styrene and 1.2mmol chlorobenzene, bromobenzene or iodobenzene, N 2 In the environment, the reaction...

Embodiment 3

[0030] 1. Same as embodiment 1.

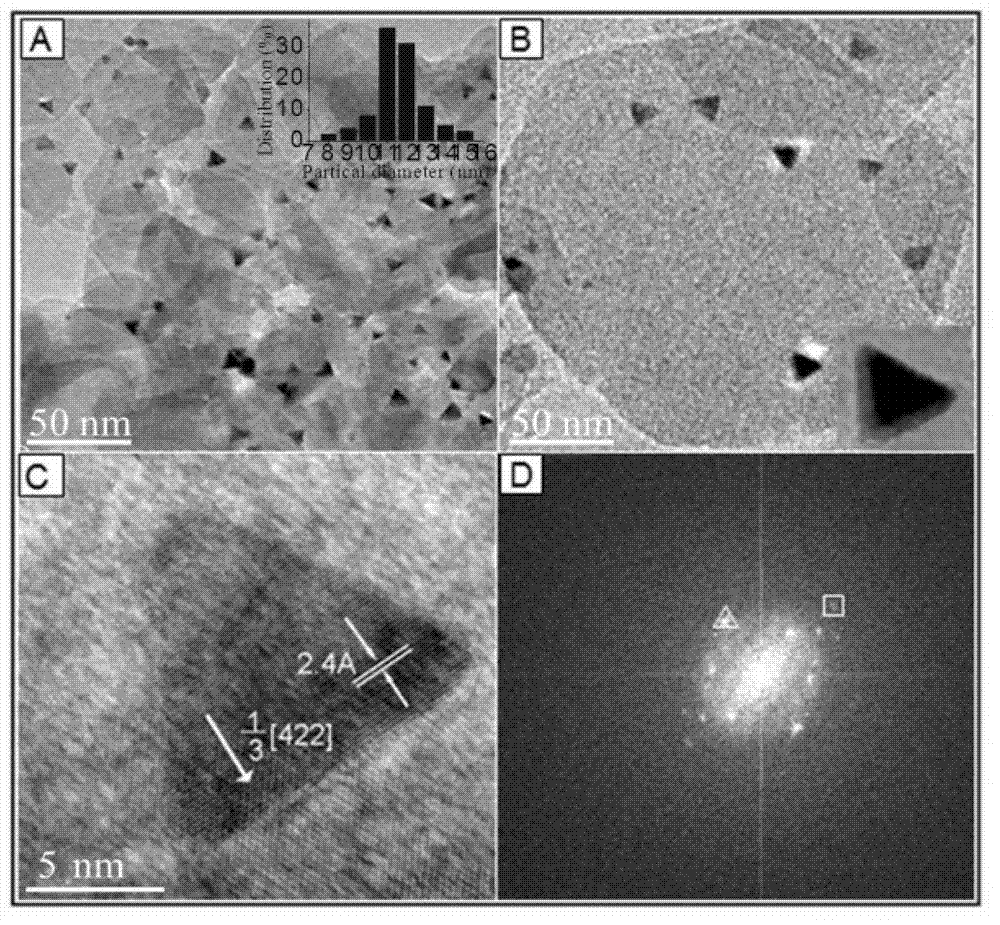

[0031] 2. Intercalate 0.45g of nitrate hydrotalcite with 0.05g of Na 2 PdCl 4 , 0.60g of KCl, and 0.82g of polyvinylpyrrolidone with a molecular weight of 40000-50000 are added together into 15ml of a mixed solution of ethylene glycol and water with a volume ratio of 0.2 and mixed uniformly, then transferred to a 20ml polytetrafluoroethylene reactor, After reacting under hydrothermal conditions at 115°C for 5 hours, the obtained product was centrifuged once with acetone, then centrifuged three times with a mixed solution of ethanol and deionized water with a volume ratio of 1:1, and dried in vacuum to obtain a hydrotalcite-loaded triangular The Pd nanocrystalline catalyst with sheet-like morphology is denoted as Pd-TRPLs / LDH, and the loading of Pd nanocrystals is 3.01wt%.

[0032] 3. The above prepared Pd-TRPLs / LDH was applied to catalyze the Heck coupling reaction. The reaction conditions were as follows: 60 mg of Pd-TRPLs / LDH was disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com