High-performance catalyst for preparing olefin through dehydrogenation of light alkane and preparation method thereof

A technology of low-carbon alkanes and catalysts, which is applied in the field of catalysts and their preparations for the dehydrogenation of low-carbon alkanes to produce corresponding olefins. It can solve the problems of complex operation steps and achieve high alkane conversion rate, selectivity and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Catalyst-A: Catalyst-A contains 0.35w%Pt, 0.7w%Sn, 1w%K 2 O, supported on a zirconium-containing high-temperature composite oxide carrier (zirconia content 1.1w%), the preparation method is as follows:

[0034] Weigh ZrOCl 2 ·8H 2 2.88g of O powder was dissolved to obtain 134ml of zirconium oxychloride solution, and 123.7g of pseudo-boehmite was weighed, and an equal-volume impregnation method (the volume of the impregnation solution was equal to the saturated water absorption of pseudo-boehmite pellets) was used to prepare pseudo-boehmite The diaspore pellets were impregnated. Place the impregnated pellets at room temperature for aging in an air atmosphere for 12 hours, then place them in a constant temperature drying oven at 180°C for 8 hours, and place the dried samples in a temperature-programmed furnace to heat them in an air atmosphere at a rate of 5°C / min. After the temperature rises to 850°C, keep the temperature for 5 hours. After cooling, take out the roas...

Embodiment 2

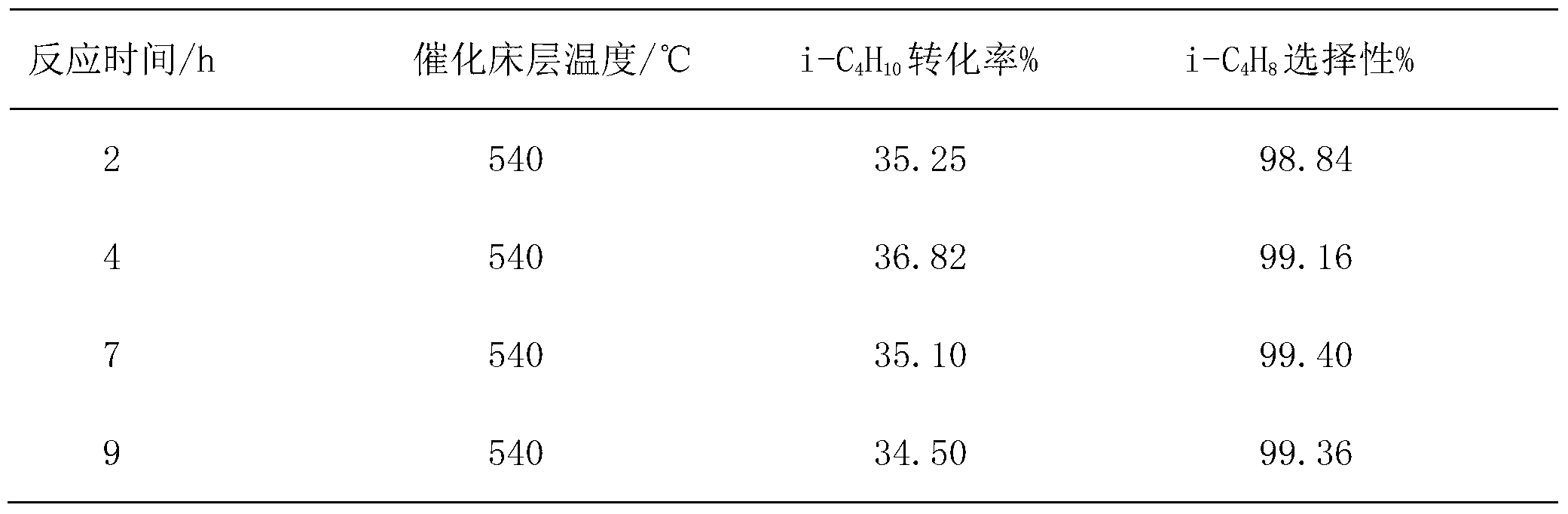

[0038] Catalyst-A is used for dehydrogenation of isobutane: the above-mentioned catalyst-A is used for the reaction of isobutane dehydrogenation to isobutene, the reaction temperature is 540°C, n (isobutane) in the material: n (H 2 ): n (H 2 O)=1:0.5:1.5, the gas space velocity (GHSV) under the standard state is 20000h -1 . The result of dehydrogenation of gained isobutane to generate isobutene is shown in Table 1.

[0039] Table 1: Results of dehydrogenation of isobutane to isobutene over Catalyst-A

[0040]

[0041] As can be seen from Table 1, at up to 20000h -1 Catalyst-A exhibited good isobutane dehydrogenation activity and isobutene selectivity at a space velocity of .

Embodiment 3

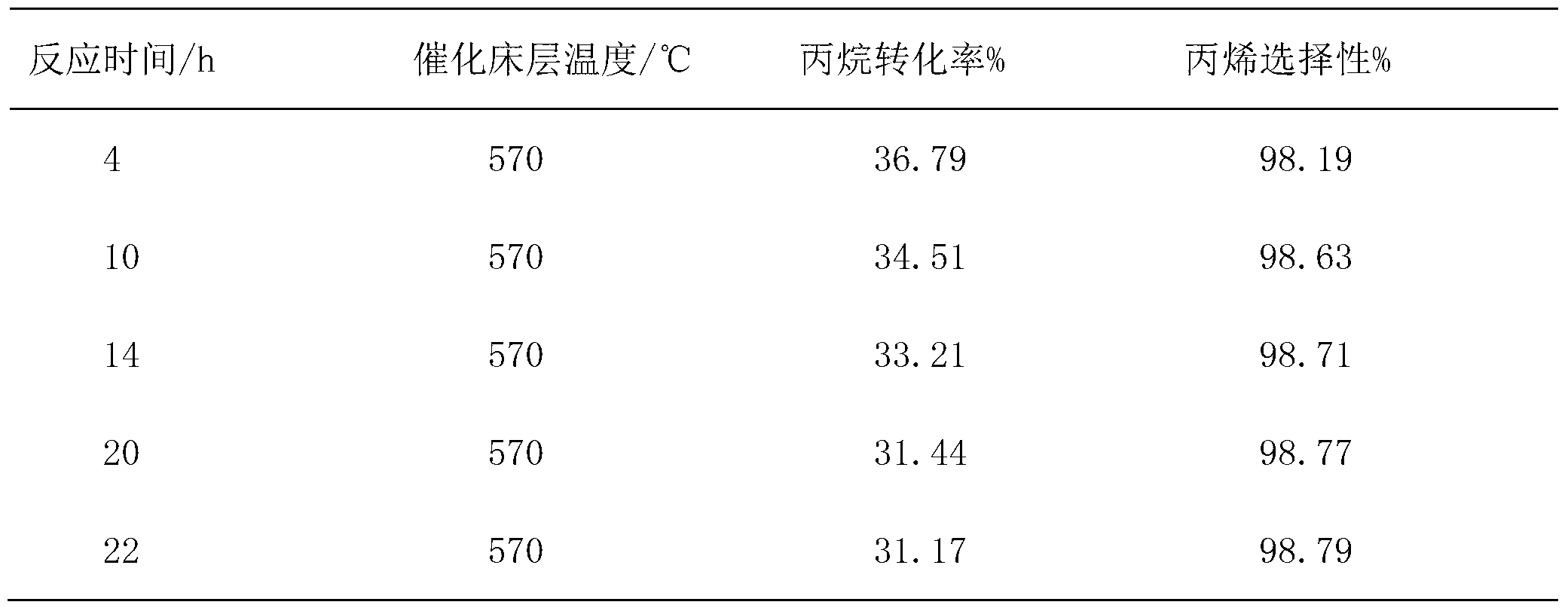

[0043] Catalyst-A is used for the dehydrogenation reaction of propane: the above-mentioned catalyst-A is used for the reaction of propane dehydrogenation to propylene, the reaction temperature is 570°C, n (propane) in the material: n (H 2 ): n (H 2 O)=1:0.2:1, GHSV is 7000h -1 . The results of the dehydrogenation of propane to propylene are shown in Table 2.

[0044] Table 2: Results of Propane Dehydrogenation to Propylene on Catalyst-A

[0045]

[0046] As can be seen from Table 2, at up to 7000h -1 Catalyst-A exhibited good propane dehydrogenation activity and propylene selectivity at a space velocity of .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com