Three-bacteria immobilized fermented winter date kvass and preparation method thereof

A technology of immobilized fermentation and winter jujube, applied in biochemical equipment and methods, preparation of alcoholic beverages, methods based on microorganisms, etc., can solve the problems of short fermentation time, low aroma, excessive alcohol content, etc., and achieve high acidity, Intense aroma, effect of improving aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

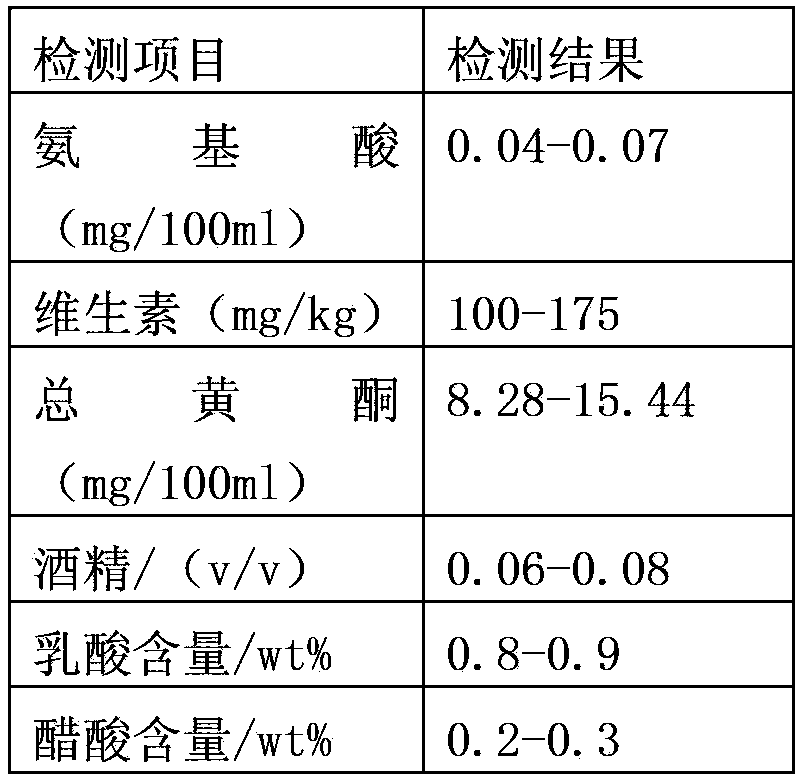

Embodiment 1

[0052] A three-bacteria immobilized fermented winter jujube kvass stock solution, made from the following raw materials per ton:

[0053] 50 kg of corn, 70 kg of winter jujube, 0.015 kg of lactic acid bacteria, 0.13 kg of yeast, 0.07 kg of acetic acid bacteria, 0.015 kg of liquefaction enzyme, 0.015 kg of glucoamylase, 0.18 kg of pectinase, and the balance of purified water;

[0054] The preparation method of the above-mentioned three-bacteria immobilized fermented winter jujube kvass stock solution comprises the following steps:

[0055](1) Grind the corn to 20 mesh, add 2 times the weight of 50°C pure water for beating, then add liquefying enzyme to raise the temperature to 105°C, keep it warm for 40 minutes, then cool it down to 50°C, add glucoamylase, keep it warm for 3 hours to obtain corn pulp;

[0056] (2) Break the winter jujube, add 4 times the weight of pure water for beating, raise the temperature to 50°C, add pectinase, keep warm for 3 hours, and get the winter ju...

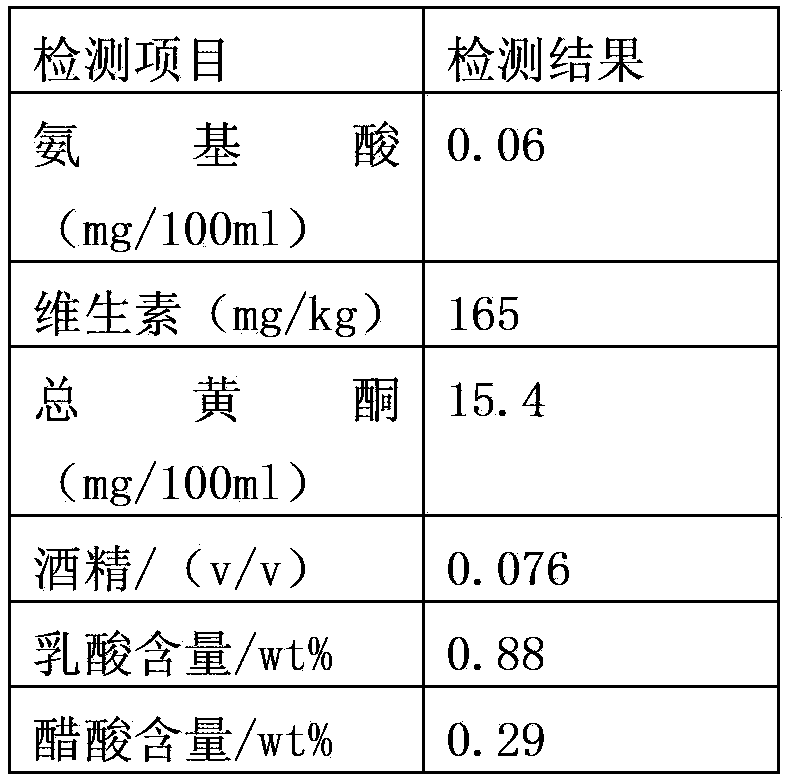

Embodiment 2

[0064] A three-bacteria immobilized fermented winter jujube kvass stock solution, made from the following raw materials per ton:

[0065] 20 kg of corn, 40 kg of winter jujube, 0.01 kg of lactic acid bacteria, 0.1 kg of yeast, 0.05 kg of acetic acid bacteria, 0.015 kg of liquefaction enzyme, 0.015 kg of glucoamylase, 0.18 kg of pectinase, and the balance of deionized water;

[0066] The preparation method of the above-mentioned three-bacteria immobilized fermented winter jujube kvass stock solution comprises the following steps:

[0067] (1) Crush the corn to 20 mesh, add 4 times the weight of 50°C deionized water for beating, then add liquefying enzyme to raise the temperature to 108°C, keep it warm for 30 minutes, then cool it down to 50°C, add glucoamylase, keep it warm for 2 hours, and get corn syrup;

[0068] (2) Break the winter jujube, add 2 times the weight of deionized water for beating, raise the temperature to 50°C, add pectinase, keep warm for 2 hours, and get the...

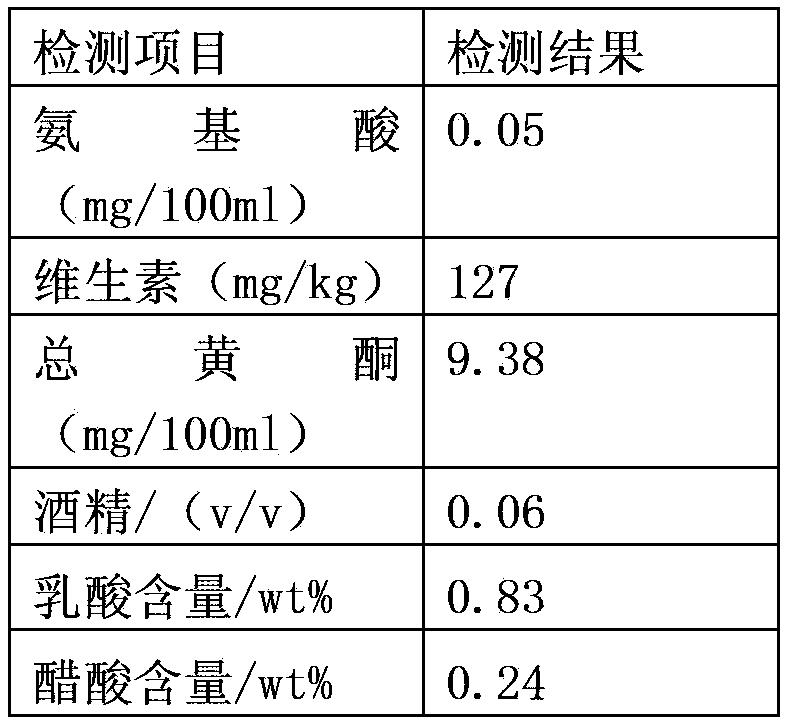

Embodiment 3

[0076] A three-bacteria immobilized fermented winter jujube kvass stock solution, made from the following raw materials per ton:

[0077] 40 kg of corn, 50 kg of winter jujube, 0.015 kg of lactic acid bacteria, 0.13 kg of yeast, 0.07 kg of acetic acid bacteria, 0.02 kg of liquefaction enzyme, 0.02 kg of glucoamylase, 0.22 kg of pectinase, and the rest of distilled water;

[0078] The preparation method of the above-mentioned three-bacteria immobilized fermented winter jujube kvass stock solution comprises the following steps:

[0079] (1) Crush the corn to 20 mesh, add 3 times the weight of 50°C distilled water for beating, then add liquefaction enzyme to raise the temperature to 108°C, keep it warm for 30 minutes, then cool it down to 50°C, add glucoamylase, keep it warm for 2 hours, and obtain corn steep liquor ;

[0080] (2) Break the winter jujube, add 3 times the weight of distilled water for beating, raise the temperature to 50°C, add pectinase, keep warm for 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com