Preparation method of carbon nanotube-reinforced polyvinyl alcohol composite fiber

A polyvinyl alcohol and carbon nanotube technology, which is applied in the field of reinforced fiber material preparation, can solve problems such as unsatisfactory carbon nanotube dispersibility, and achieve the effects of excellent medical value, large aspect ratio, and good dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Use dimethyl sulfoxide / water solution with a volume ratio of 3:1 as the solvent.

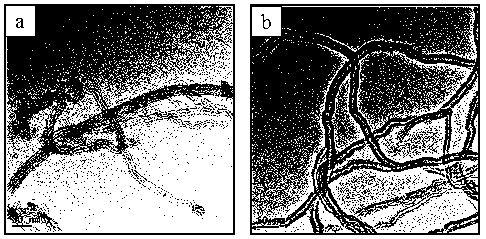

[0022] Add 44.5 mg of tea polyphenols to 10 ml of the above solvent, stir magnetically for 10 minutes, then add 14.8 mg of multi-walled carbon nanotubes, ultrasonicate for 30 minutes, and leave for one day to obtain a well-dispersed carbon nanotube / tea polyphenol solution.

[0023] Weigh 15.24g of polyvinyl alcohol into a dry two-necked flask, add 80ml of solvent, and add the above-mentioned well-dispersed carbon nanotube / tea polyphenol solution, and stir for 4 hours at 90°C without a magnetic field to obtain a solid content of 16wt % of polyvinyl alcohol / carbon nanotubes / tea polyphenol solution is the spinning solution, wherein the content of carbon nanotubes is 4×10 -3 g / mL.

[0024] Preparation of a carbon nanotube solution comparison example: 14.8 mg of multi-walled carbon nanotubes were added to 10 ml of solvent, ultrasonicated at a frequency of 45 kHz for 30 minutes, and a carbon n...

Embodiment 2

[0031] Weigh 15.24g of polyvinyl alcohol in a dry two-necked flask, add 80ml of solvent, and add the well-dispersed carbon nanotube / tea polyphenol solution prepared in Example 1, and stir for 4 hours at 90°C without a magnetic field to prepare Obtain a carbon nanotube and polyvinyl alcohol solution with a solid content of 14wt%, wherein the content of the carbon nanotube is at 2×10 -3 g / mL.

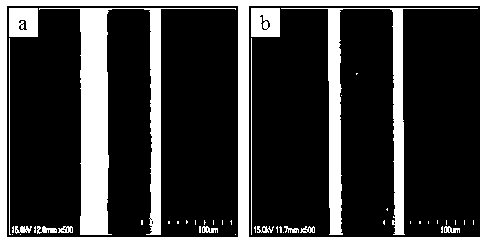

[0032] Add the well-dispersed polyvinyl alcohol / carbon nanotube / tea polyphenol solution into the spinning tube, control the temperature at 60°C, the temperature of the coagulation bath at -20°C, and the composition of the coagulation bath by volume, methanol: water is 5: 1. The distance between the spinneret hole and the coagulation bath is 0.6cm, and the winding speed is 40m / min to obtain carbon nanotube-reinforced polyvinyl alcohol primary fibers.

[0033] Put the solidified and washed fiber at room temperature for one day and then stretch it on a dry heat stretching machine. The f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com