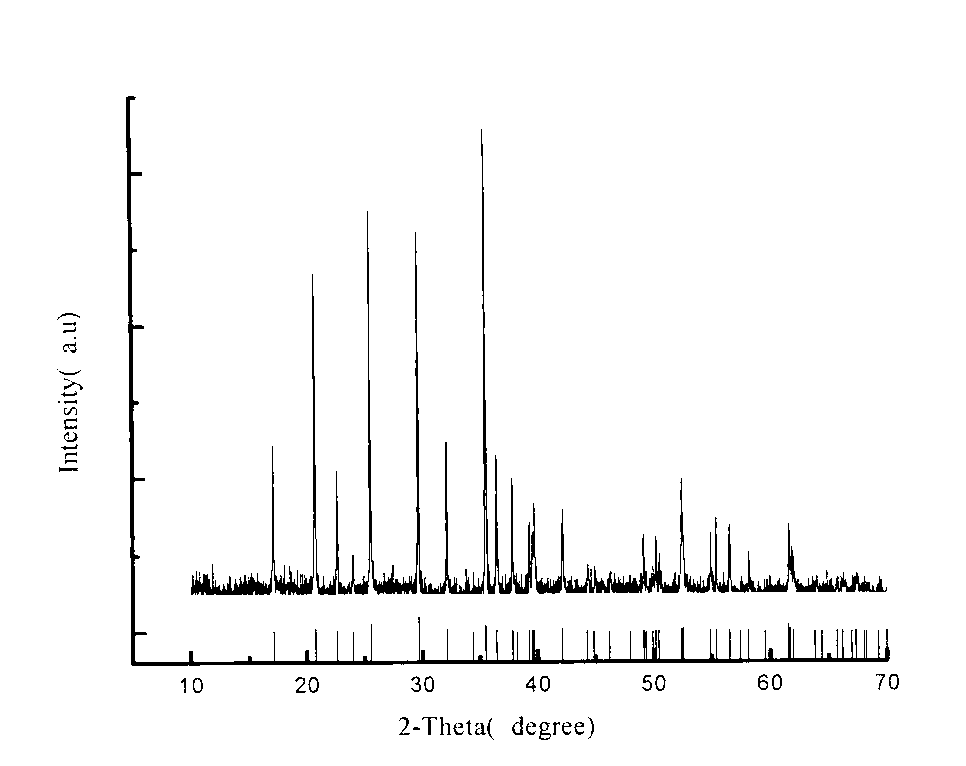

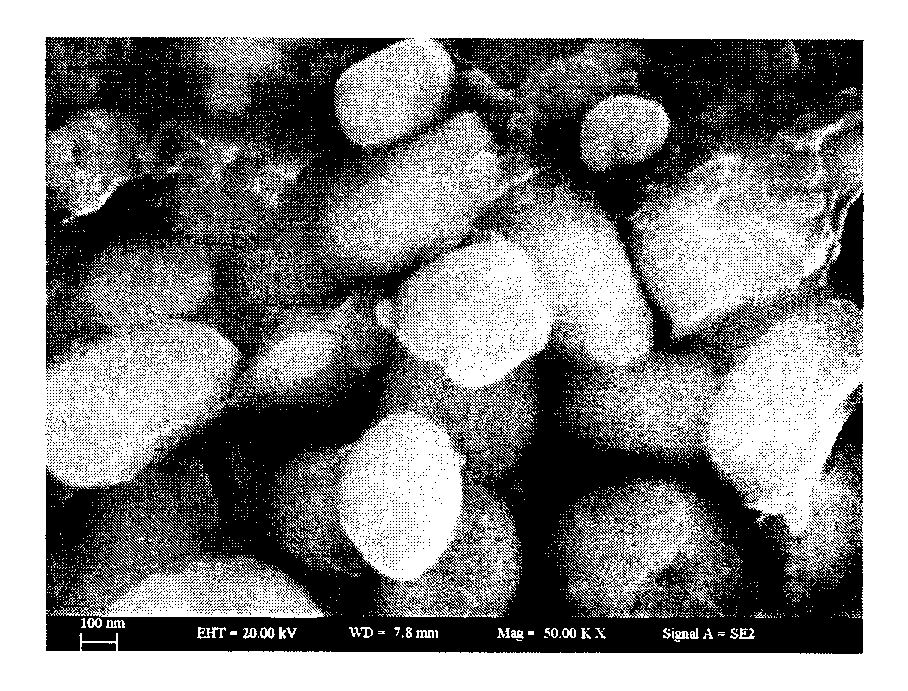

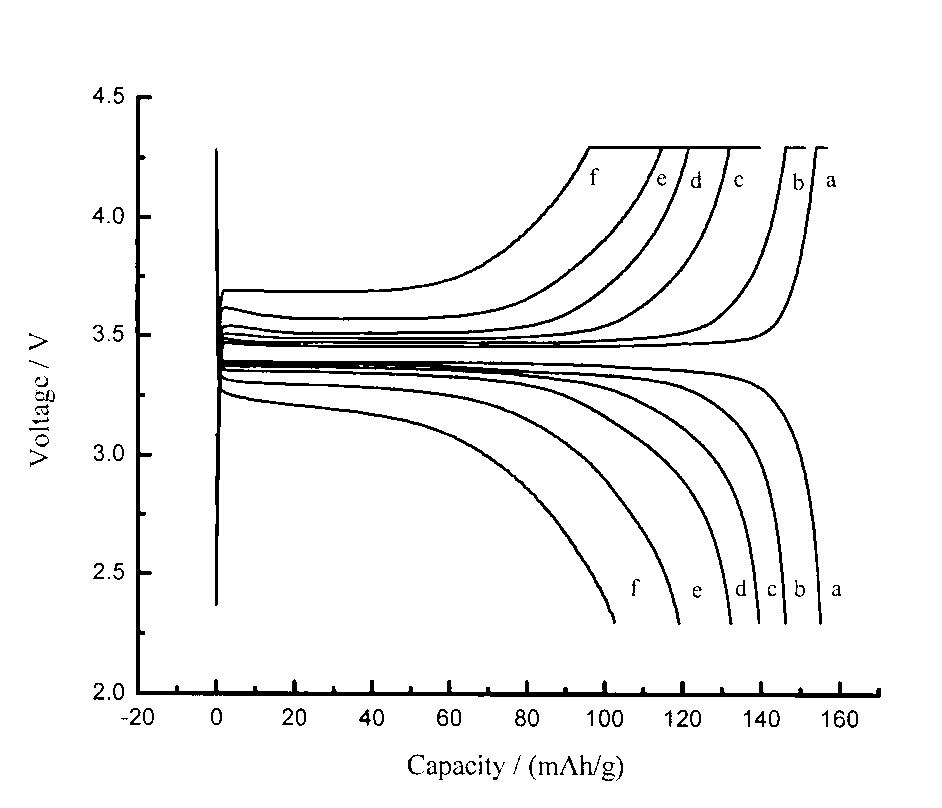

Preparation method of phosphate potential boron-doped carbon-wrapped phosphoric acid iron-lithium material

A carbon-coated lithium iron phosphate and phosphorus-positioned boron technology, which is applied to electrical components, battery electrodes, circuits, etc., can solve the problems of difficulty in controlling the uniformity of synthesis conditions, uneven distribution of elements, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] a. The molar ratio is Li:Fe:B:C 2 h 2 o 4 =1:1:0.05:1.2, the amount of carbon source added is 20 wt%, add deionized water, lithium acetate and oxalic acid into the container, stir to dissolve, then add iron phosphate, boric acid and starch, stir at a temperature of 40°C After 15 hours to evaporate to dryness, the stirring speed was 320 r / min, and the evaporated to dryness product was obtained;

[0020] b. Place the evaporated product of step a in an oven at a temperature of 120° C. to fully dry it and grind it thoroughly to obtain a mixture powder;

[0021] c, the mixture powder of step b in N 2 Carry out rapid high-temperature heat treatment under the protection of the atmosphere. The heat treatment conditions are: the flow rate of the protective gas is 0.5 L / min, the temperature is raised at a heating rate of 6°C / min, and the temperature is 450°C for 4 hours at a constant temperature;

[0022] d. Finally, naturally cool down to room temperature with the furnace to...

Embodiment 2

[0024] a. The molar ratio is Li:Fe:B:C 2 h 2 o 4 = 1:1:0.15:1.3, the amount of carbon source added is 5 wt%, add deionized water, lithium oxalate and oxalic acid into the container, stir to dissolve, then add iron phosphate, boric acid and sucrose, and stir at a temperature of 90 °C After 1 hour until evaporated to dryness, the stirring speed was 200 r / min, and the evaporated product was obtained;

[0025] b. Place the evaporated product of step a in an oven at a temperature of 90° C. to fully dry it and grind it thoroughly to obtain a mixture powder;

[0026] c, the mixture powder of step b in N 2 Carry out rapid high-temperature heat treatment under the protection of the atmosphere. The heat treatment conditions are: the gas flow rate of the protective gas is 0.3 L / min, the temperature is raised at a heating rate of 8°C / min, and the temperature is constant for calcination at 650°C for 3 hours;

[0027] d. Finally, naturally cool down to room temperature with the furnace ...

Embodiment 3

[0029] a. The molar ratio is Li:Fe:B:C 2 h 2 o 4 = 1:1:0.20:3.5, the amount of carbon source added is 15 wt%, add deionized water, lithium oxide and oxalic acid into the container, stir to dissolve, then add iron phosphate, boric acid and glucose, stir at a temperature of 45 °C After 13 hours to evaporate to dryness, the stirring speed was 240 r / min, and the product was evaporated to dryness;

[0030] b. Place the evaporated product of step a in an oven at a temperature of 100° C. for sufficient drying, and then fully grind to obtain a mixture powder;

[0031] c, the mixture powder of step b in N 2 Carry out rapid high-temperature heat treatment under the protection of the atmosphere. The heat treatment conditions are as follows: the flow rate of the protective gas is 0.6 L / min, the temperature is raised at a heating rate of 9°C / min, and the temperature is constant for calcination at a temperature of 750°C for 0.5 hours;

[0032] d. Finally, naturally cool down to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com