Preparation method of phenylacetic acid

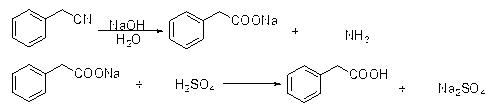

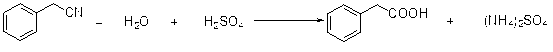

A technology of phenylacetic acid and phenylacetonitrile, which is applied in the field of phenylacetic acid prepared by hydrolysis of phenylacetonitrile, can solve problems such as poor operating environment, difficult recovery, cumbersome operation process, etc., achieve product appearance and quality satisfaction, avoid difficult processing, and atom economy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

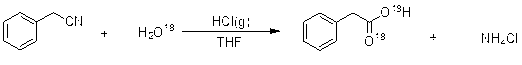

[0033] The preparation method of phenylacetic acid of the present invention comprises the following steps:

[0034] 1) Heat benzyl nitrile to 50~100°C, then add hydrochloric acid dropwise to benzyl nitrile or drop molten benzyl nitrile into hydrochloric acid, the molar ratio of hydrochloric acid to benzyl nitrile is 1.2~5:1, the dropwise addition is completed Post-insulation reaction 1~5 hour, the mass content of phenylacetonitrile in the reaction system terminates reaction when being less than 5%; The massfraction of described hydrochloric acid is preferably 15%~37%;

[0035] 2) Recover the unreacted phenylacetonitrile in the reaction system of step 1) by distillation under reduced pressure until the mass content of phenylacetonitrile in the reaction system is less than 0.2%, then add water to the reaction system, stir and miscible, then cool and crystallize, and suction filter, The obtained crystals are washed with water and dried to obtain the phenylacetic acid product; amm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com