Temperature-resistant and wear-resistant nano composite functional coating

A functional coating and nano-composite technology, applied in the field of coatings and functional coatings, can solve the problems of high friction coefficient, insufficient temperature and corrosion resistance, etc., and achieve excellent temperature resistance, excellent synergistic effect, good industrial application prospects and practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

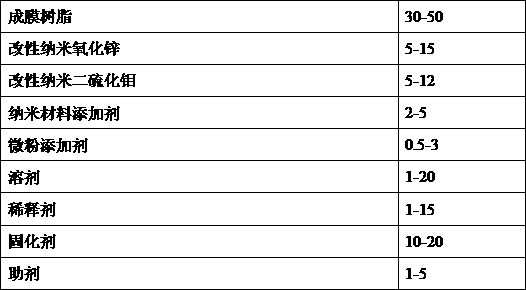

Method used

Image

Examples

preparation example 1

[0041] Preparation Example 1: Modified Nano Zinc Oxide

[0042] Add 1.25 L of deionized water into the reactor, add 2.5 g of borax while stirring, heat up to about 80 °C, keep stirring for about 30 minutes, add 100 g of nano-zinc oxide with a particle size of 100-500 nm, and continue to keep stirring for 70 minutes The suspension was obtained in about 10 minutes, lowered to room temperature, stopped stirring, and dried to dryness at 120°C to obtain the modified nano-zinc oxide. In terms of mass percentage, the nano-zinc oxide was 97.57% and the borax was 2.43%.

[0043] By selecting nano-zinc oxides with different particle sizes, modified nano-zinc oxides with different particle sizes can be prepared.

preparation example 2

[0044] Preparation Example 2: Modified Nano Molybdenum Disulfide

[0045] Add 100 g of emulsifier OP-10 into 500 ml of absolute ethanol, mix well and add 50 g of nano-MoS with a particle size of 100-500 nm 2 Fine powder, stirred or ball milled for 3 hours, finally filtered, dried, and crushed for later use.

[0046] By selecting nano-MoS with different particle sizes 2 , modified nano-MoS with different particle sizes can be prepared 2 .

Embodiment 1

[0048] With 35 parts by weight of bisphenol A-epoxy resin, 12 parts by weight of modified nano-zinc oxide, 8 parts by weight of modified nano-molybdenum disulfide, 4 parts by weight of nanomaterial additives, 2 parts by weight of micropowder additives, 15 parts by weight of butyl acetate , 10 parts by weight of pentaerythritol triacrylate, 11 parts by weight of diethylenetriamine and 3 parts by weight of auxiliary agents are dropped into a high-speed dispersant for uniform dispersion and then ground, filtered, and packaged to obtain the nanocomposite functional coating NC of the present invention. 1.

[0049] Among them, the particle sizes of the modified nano-zinc oxide and the modified nano-molybdenum disulfide are both 120 nm.

[0050] Among them, the nanomaterial additive is a mixture of nano-titanium nitride and nano-silicon carbide with a weight ratio of 1:1, both of which have a particle size of 140 nm; Mixture, particle size 5.2 μm.

[0051] Wherein, the auxiliary ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com