Method for manufacturing window layers of copper, zinc, tin and sulfur solar cells

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, electrical components, final product manufacturing, etc., to achieve the effects of good electrical properties, high adhesion strength, and easy-to-control film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

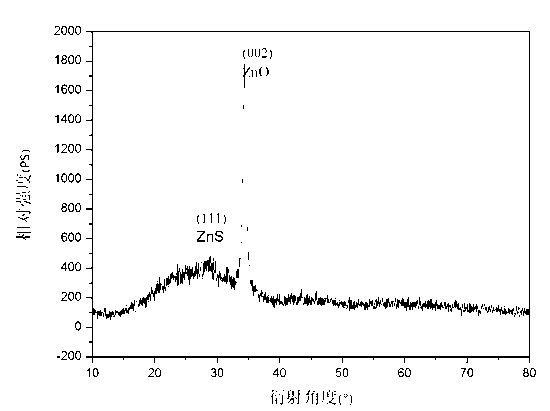

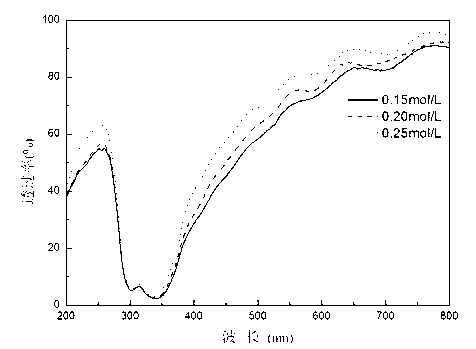

[0022] A method for preparing a window layer of a copper-zinc-tin-sulfur solar cell, using a spin-coating method to prepare ZnO nano-array crystal seeds, using a hydrothermal method to grow a ZnO nano-array, and using a hydrothermal method to vulcanize and grow a ZnS shell structure, has the following process and step:

[0023] a) Cleaning of the glass substrate: Carry out surface cleaning treatment on the glass slide, put into triton aqueous solution, acetone solution, absolute alcohol solution and deionized water in order to sonicate for 15 minutes each, and then dry the glass slide.

[0024] b) Preparation of ZnO nanoarray seed crystals: ZnO seed crystals were prepared by spin coating method. Ethanolamine and zinc acetate are dissolved in ethanol at a concentration of 0.05mol / L, and are uniformly ultrasonicated. Put the glass slide substrate into the glue homogenizer, drop the seed crystal solution on the substrate with a dropper, the rotation speed is 1000 r / min, and the ...

Embodiment 2

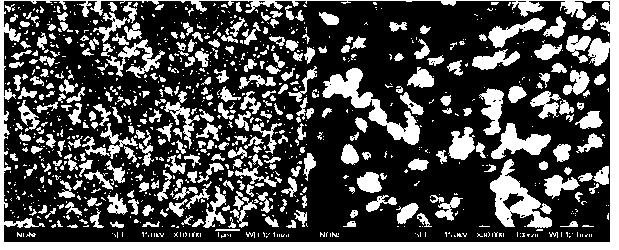

[0028] The operation steps of this example are basically the same as those of Example 1, except that the concentration of TAA in the growth solution in step d) is 0.15 mol / L. Figure 4 is a scanning electron microscope image. The tip of the nanorod is in the shape of a hexagonal prism with a diameter of about 90nm.

Embodiment 3

[0030] The operation steps of this example are basically the same as those of Example 1, except that the concentration of TAA in the growth solution in step d) is 0.25 mol / L. Figure 5 is a scanning electron microscope image. The tip of the nanorod is in the shape of a hexagonal prism, and the diameter ranges from 120-140nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com