Preparation method of lithium ion battery silicon oxide/carbon composite negative pole material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, complex process, and limited industrialization, and achieve low cost, simple preparation process, and uniform distribution of components Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

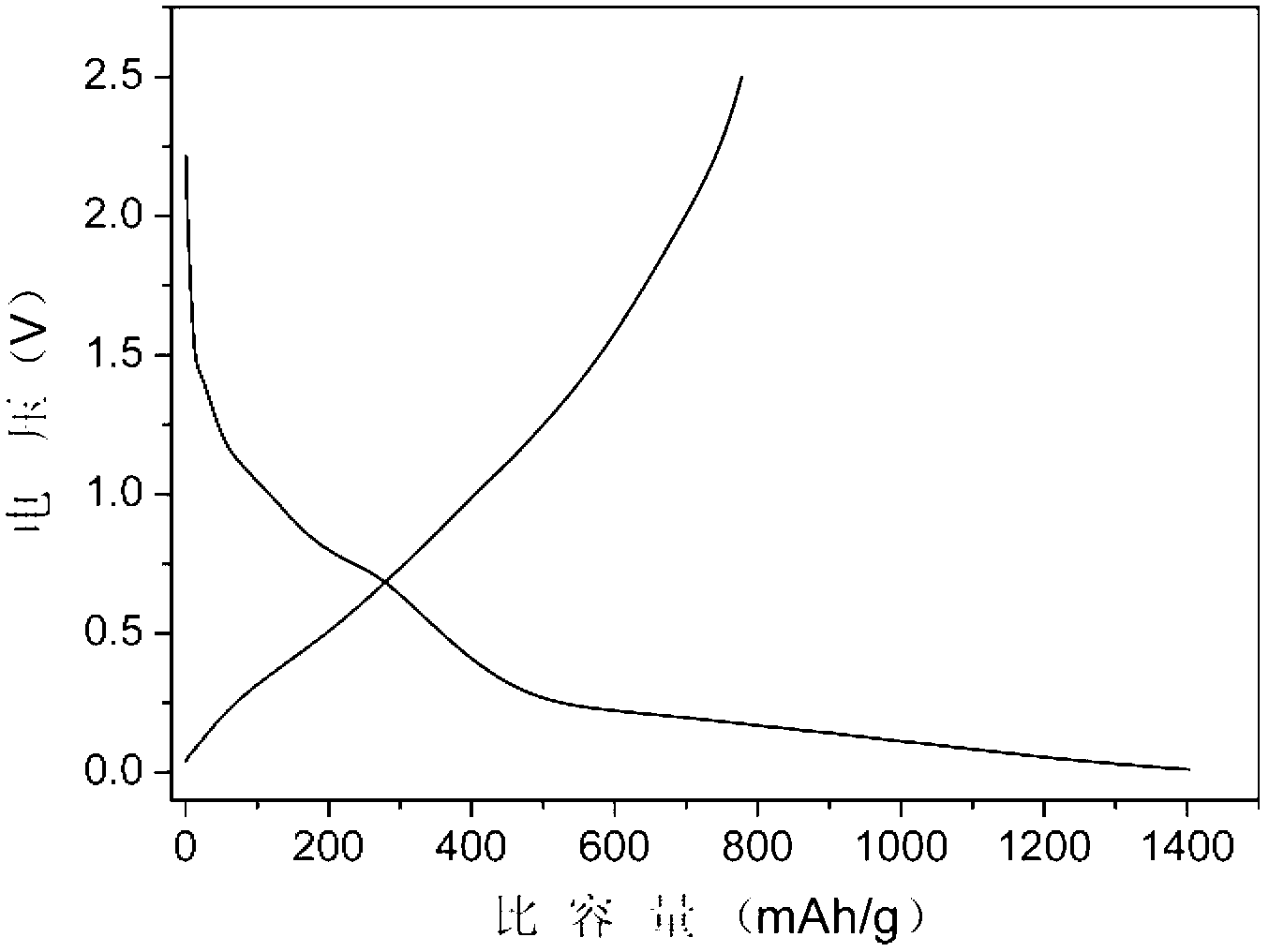

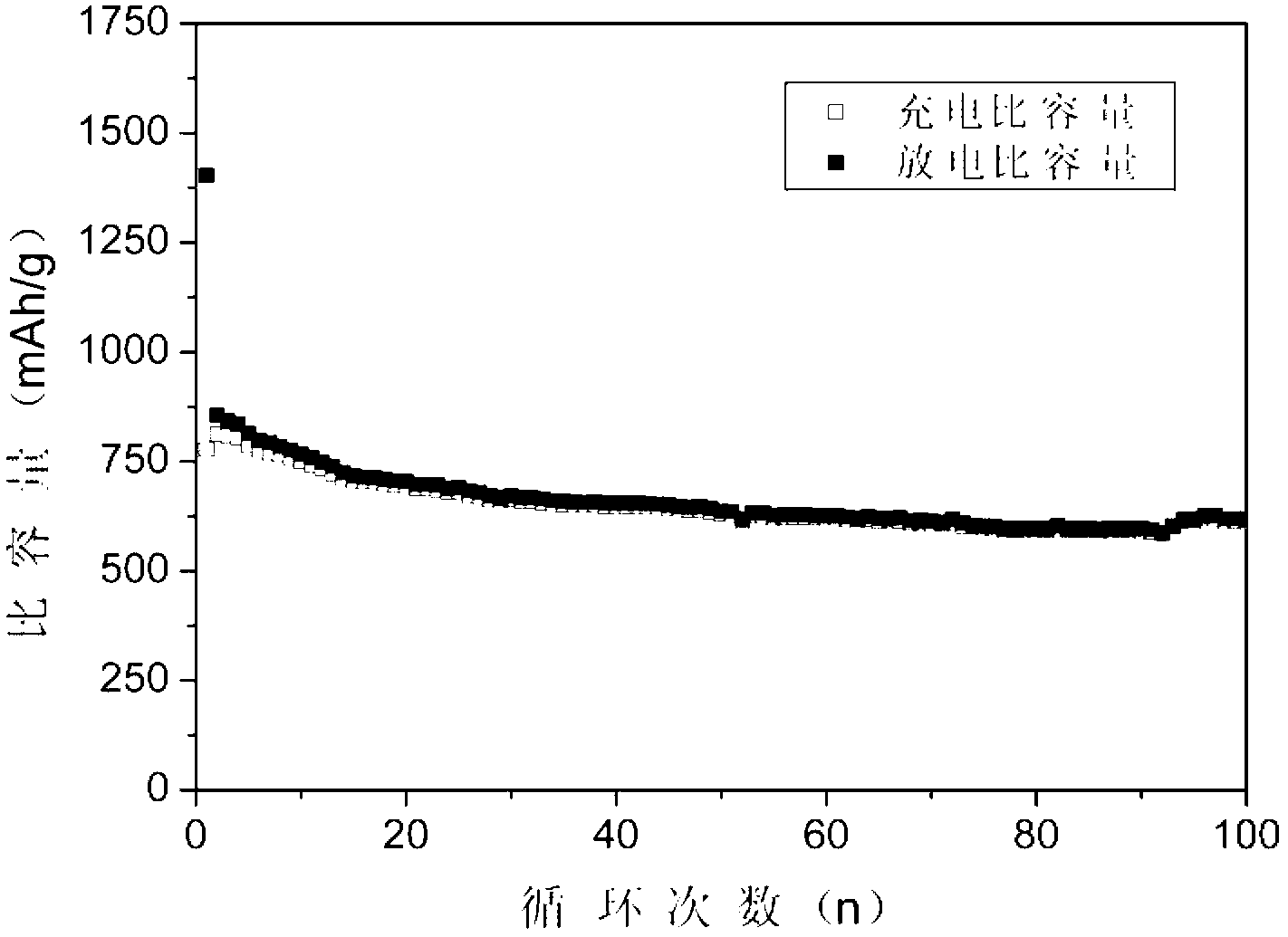

[0034]Weigh 6.6 g of resorcinol, dissolve it in 10 ml of deionized water, then add 4.4 ml of formaldehyde solution (37~40% by weight), stir evenly to form a solution, this solution is recorded as solution A; measure 30 Dissolve 1 ml tetraethyl orthosilicate in 20 ml absolute ethanol, then add 10 ml deionized water, stir evenly to form a transparent solution, which is recorded as solution B; under stirring conditions, add 0.128 g Na 2 CO 3 , this solution is recorded as solution C; under stirring conditions, add hydrochloric acid dropwise to solution B to adjust the pH value of the solution at 3, and this solution is recorded as solution D; add solution D dropwise to solution C, and continue stirring for 1 h , moved into a water bath for heat preservation, the temperature of the water bath was 60 o C, gel was formed after standing; add absolute ethanol to the gel for aging, replace absolute ethanol every 24 h, repeat twice; put the gel in 80 o Dry in a C oven to obtain a prec...

Embodiment 2

[0037] Weigh 6.6 g of resorcinol, dissolve it in 10 ml of deionized water, then add 4.4 ml of formaldehyde solution (37~40% by weight), stir evenly to form a solution, this solution is recorded as solution A; measure 20 Dissolve 1 ml tetraethyl orthosilicate in 20 ml absolute ethanol, then add 10 ml deionized water, stir evenly to form a transparent solution, which is recorded as solution B; under stirring conditions, add 0.256 g Na 2 CO 3 , this solution is recorded as solution C; under stirring conditions, add hydrochloric acid dropwise to solution B to adjust the pH value of the solution at 4, and this solution is recorded as solution D; add solution D dropwise to solution C, and continue stirring for 1 h , moved into a water bath for heat preservation, the temperature of the water bath was 60 o C, gel was formed after standing; add absolute ethanol to the gel for aging, replace absolute ethanol every 24 h, repeat twice; put the gel in 80 o Dry in a C oven to obtain a pre...

Embodiment 3

[0040] Weigh 6.6 g of resorcinol, dissolve it in 10 ml of deionized water, then add 2.2 ml of formaldehyde solution (37-40% by weight), stir evenly to form a solution, and record this solution as solution A; measure 15 Dissolve 1 ml tetraethyl orthosilicate in 20 ml absolute ethanol, then add 10 ml deionized water, stir evenly to form a transparent solution, which is recorded as solution B; under stirring conditions, add 0.128 g Na 2 CO 3 , this solution is recorded as solution C; under stirring conditions, add hydrochloric acid dropwise to solution B to adjust the pH value of the solution at 3, and this solution is recorded as solution D; add solution D dropwise to solution C, and continue stirring for 1 h , moved into a water bath for heat preservation, the temperature of the water bath was 60 o C, gel was formed after standing; add absolute ethanol to the gel for aging, replace absolute ethanol every 24 h, repeat twice; put the gel in 80 o Dry in a C oven to obtain a prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com