Mass production process of polycrystalline high-content benzoic acid alogliptin

A mass production, benzoic acid technology, applied in the preparation of carboxylate, organic chemistry and other directions, can solve the problems of difficult removal, unavoidable, affecting the purity of finished products, etc., to achieve the effects of easy removal, low price and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

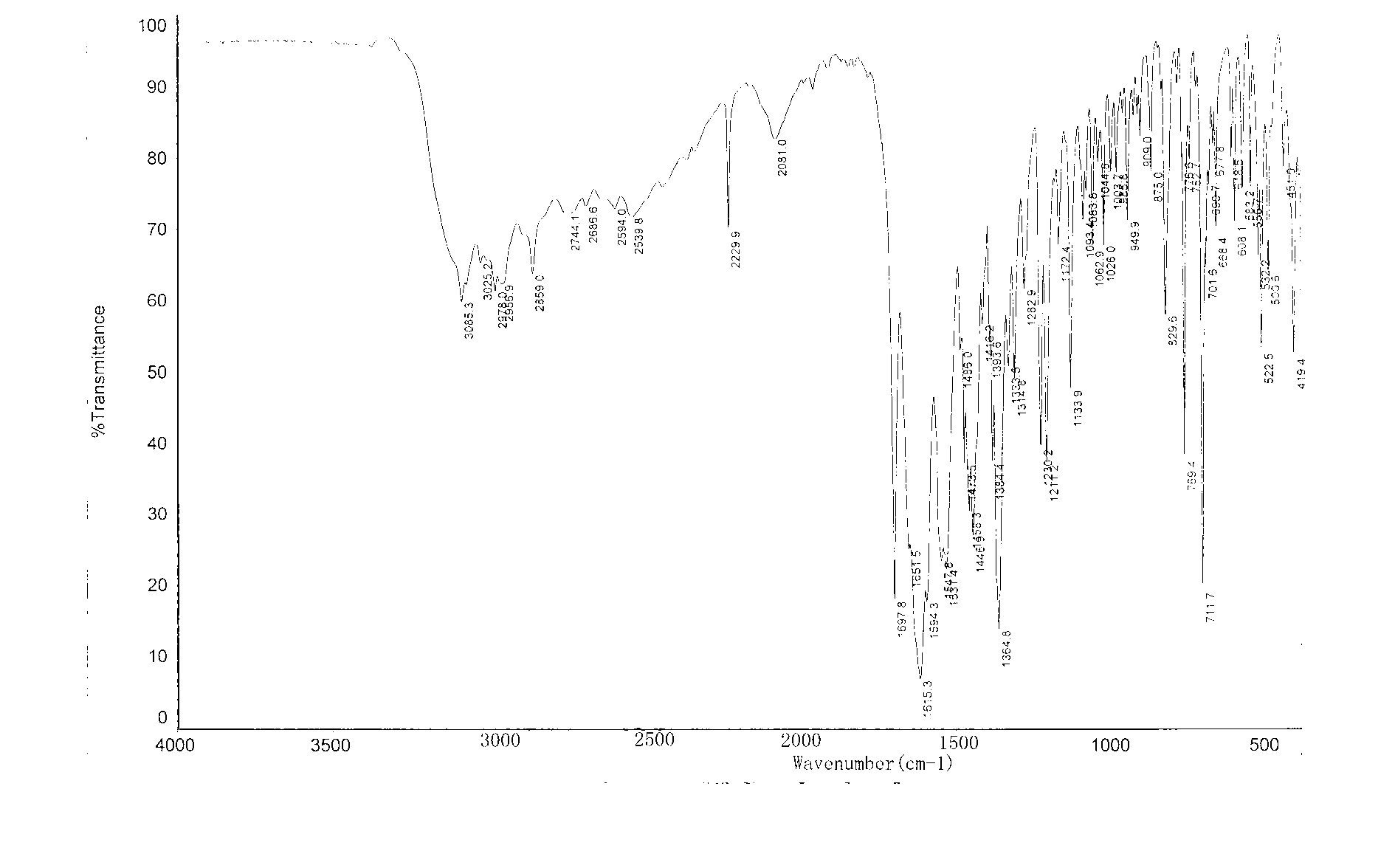

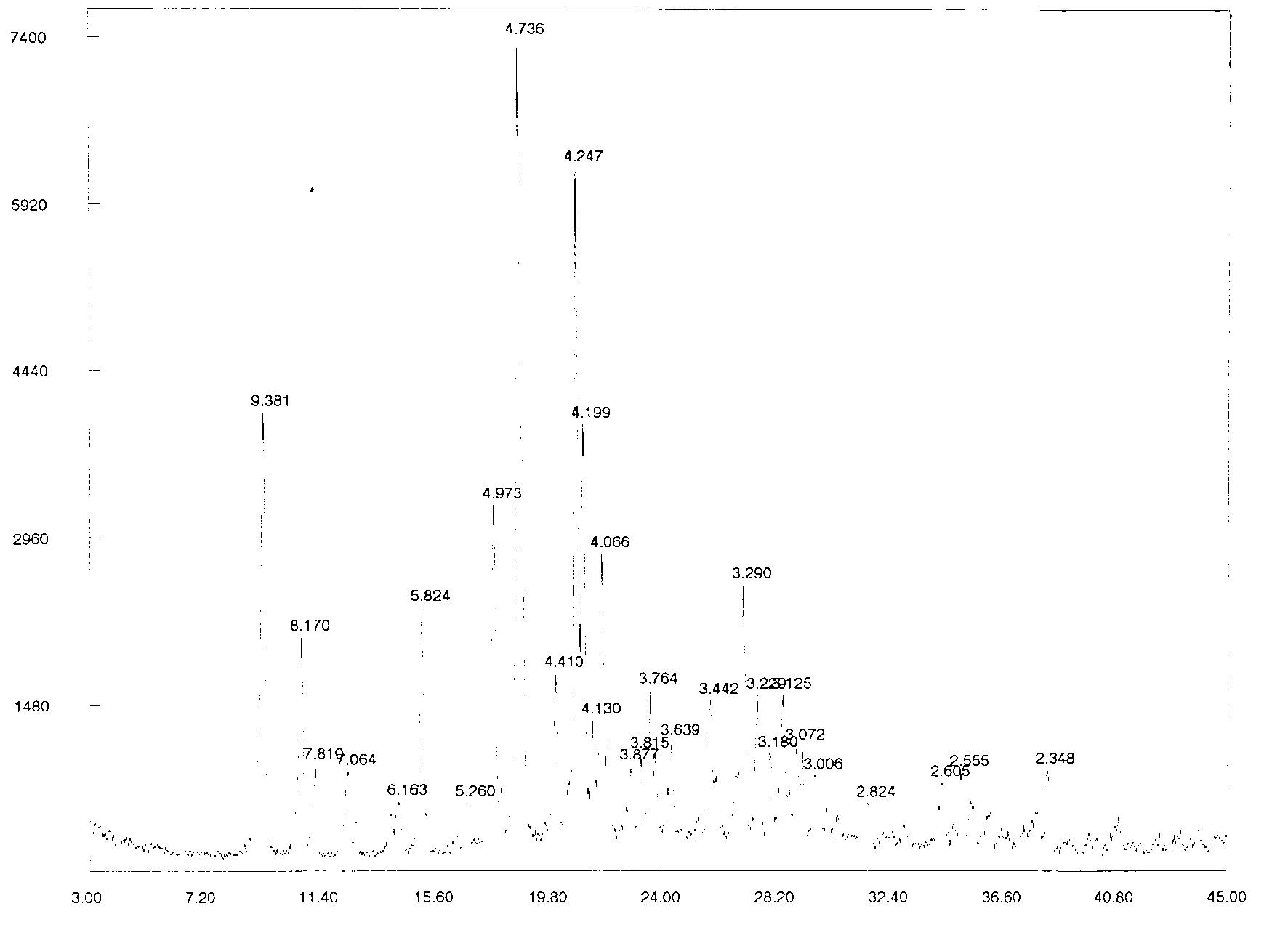

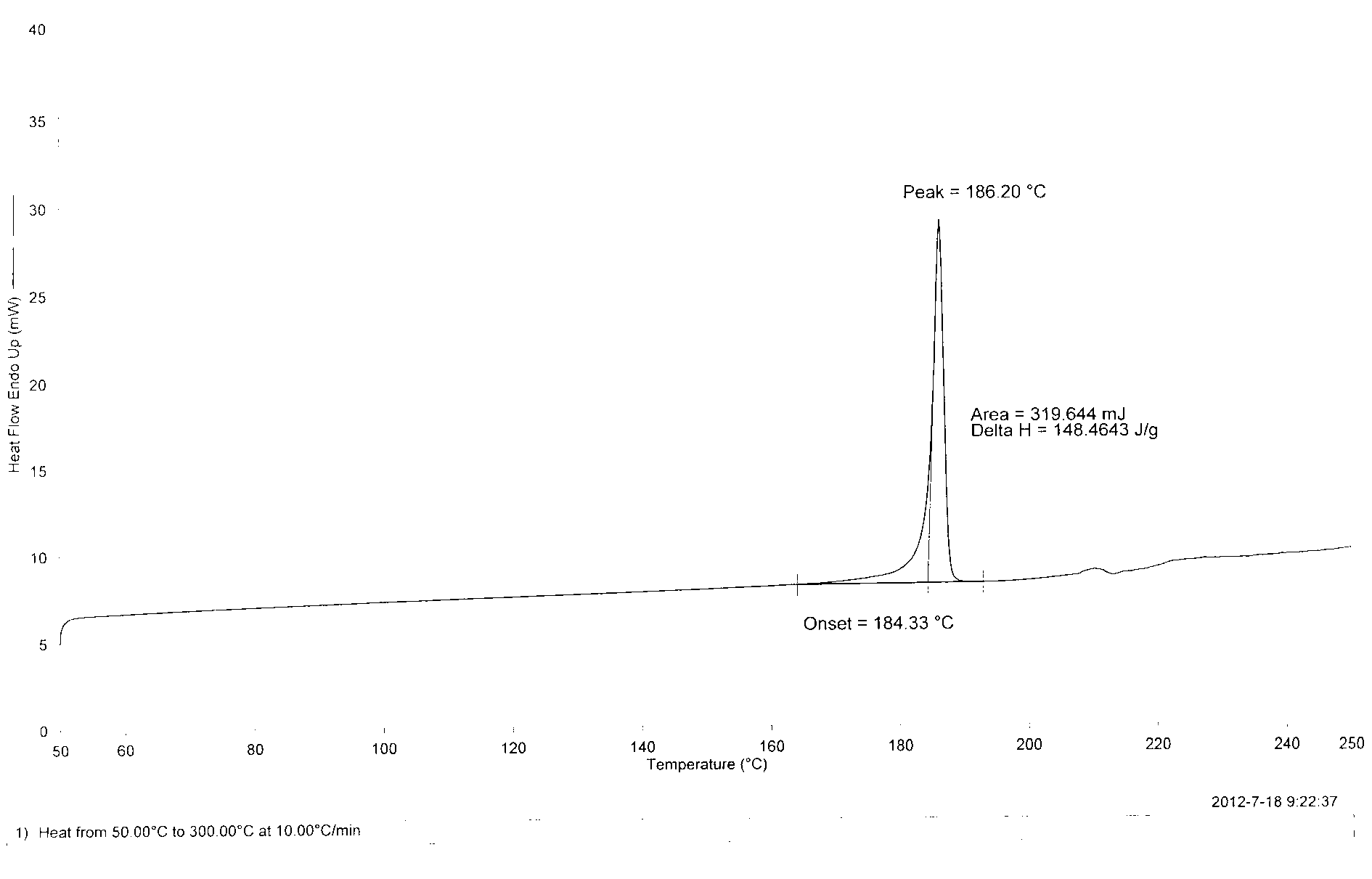

Image

Examples

Embodiment Construction

[0032] Alogliptin can be prepared by the method provided by CN101360723A, and benzoic acid is commercially available analytically pure from Shanghai Suyi Chemical Reagent Co., Ltd.

[0033] Get benzoic acid 5kg, put 200 liters of reactors, add 100 liters of pure water, stir and heat up and reflux for 1 hour. The temperature of the reaction solution was lowered to 55-60°C, centrifuged, and the filter cake was air-dried at 60-65°C for 10-12 hours to obtain 2.41 kg of refined white needle-shaped benzoic acid (HPLC: 99.9%); yield: 48.2%.

[0034] 2 Preparation of alogliptin benzoate:

[0035] Take 3.11kg of alogliptin (HPLC: 99.6%) and 1.13kg of refined benzoic acid, and put them in a 50-liter reaction kettle. Add 15L of ethanol, heat to dissolve, heat to reflux for 2 to 3 hours, a white solid precipitates out. Stop heating, naturally cool to room temperature, stir and crystallize for 10-12 hours. After centrifugation, the solid was washed with 1 liter of ethanol and air-dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com