Hollow core shell structure Au@TiO2 nano-composite material and preparation method thereof

A nanocomposite material, core-shell structure technology, applied in the field of hollow core-shell structure AuTiO2 nanocomposite material and its preparation, can solve the problems of complex synthesis steps, difficult to wash clean, cumbersome experimental operations, etc., and achieve the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a hollow core-shell structure AuTiO 2 A method for preparing a nanocomposite, wherein the method comprises the following steps:

[0024] 1) preparing a colloidal solution of Au nanoparticles with a particle size of 3 to 7 nm;

[0025] 2) After first contacting the colloidal solution of Au nanoparticles obtained in step 1) with the mixed solution of alcohol and water with 1-4 carbon atoms, and then carrying out the second contact with the titanium source, the product after the second contact For hydrothermal crystallization, the titanium source is one or more of titanium tetrafluoride, tetrabutyl titanate and titanium trichloride.

[0026] According to the preparation method of the present invention, the content of Au nanoparticles in the colloidal solution of Au nanoparticles obtained in step 1) can be changed within a wide range. Generally, the content of Au nanoparticles in the colloidal solution of Au nanoparticles obtained in step 1) can be ...

Embodiment 1

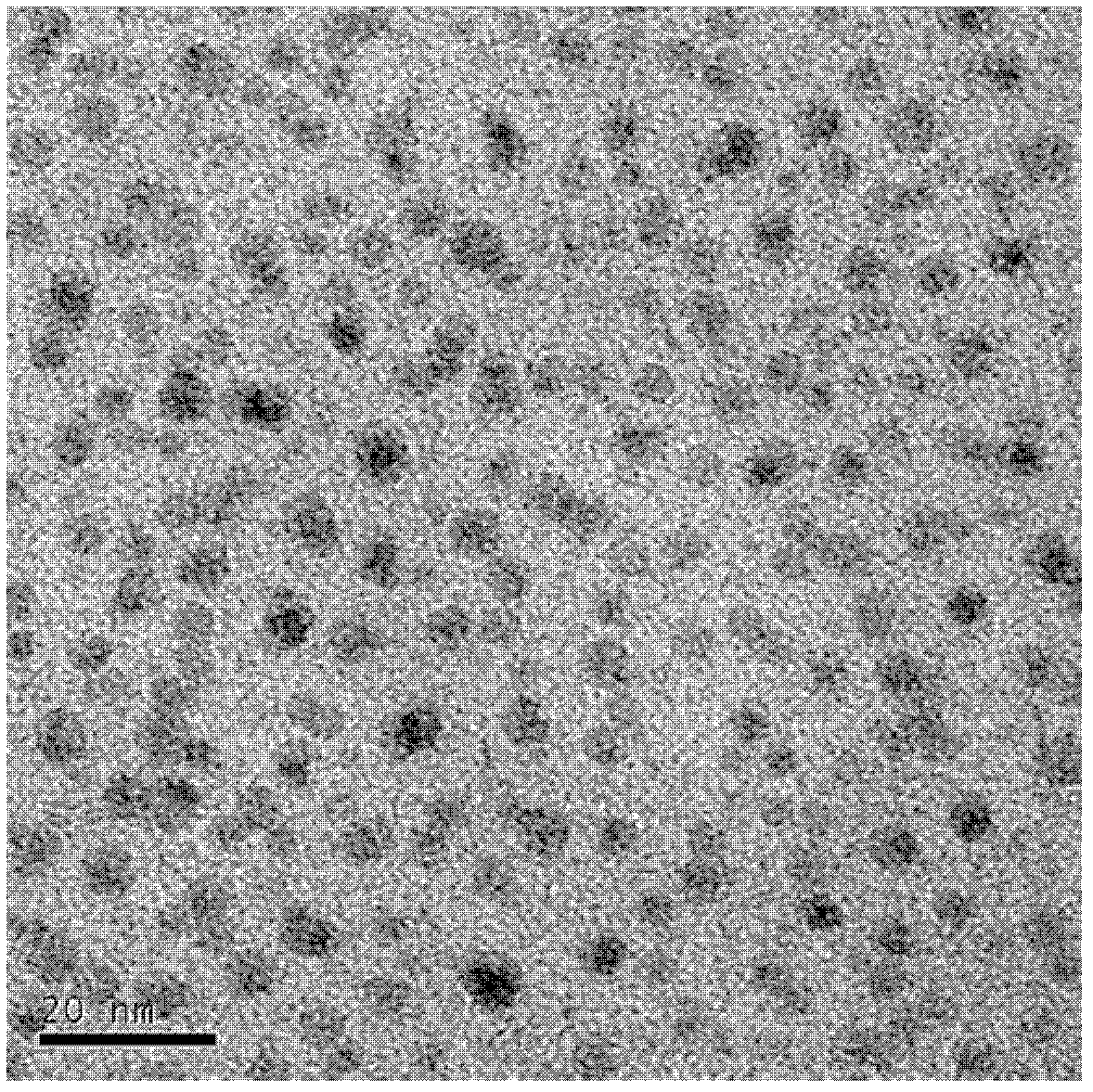

[0048] 1) At 25°C, measure 190 mL of distilled water and place it in a 250 mL round-bottomed flask. After magnetically stirring for 5 minutes, add 5 mL of HAuCl dropwise into the round-bottomed flask 4 Aqueous solution (concentration is 10mmol / L), after magnetic stirring for 10min, add dropwise 5mL sodium citrate aqueous solution (concentration is 10mmol / L) to the round bottom flask, after magnetic stirring for 10min, add 3.0mL hydroboration to the round bottom flask instantly Sodium aqueous solution (concentration is 0.1mol / L), after continuing to stir at 25°C for 12 hours, a colloidal solution of Au nanoparticles of 3 to 7 nm can be obtained, wherein the content of Au nanoparticles in the colloidal solution of Au nanoparticles is 0.00485% by weight . Drop the colloidal solution of Au nanoparticles on the copper grid, and after air-drying, observe and take pictures with a transmission electron microscope, and obtain the transmission electron microscope photos of the Au nanopa...

Embodiment 2

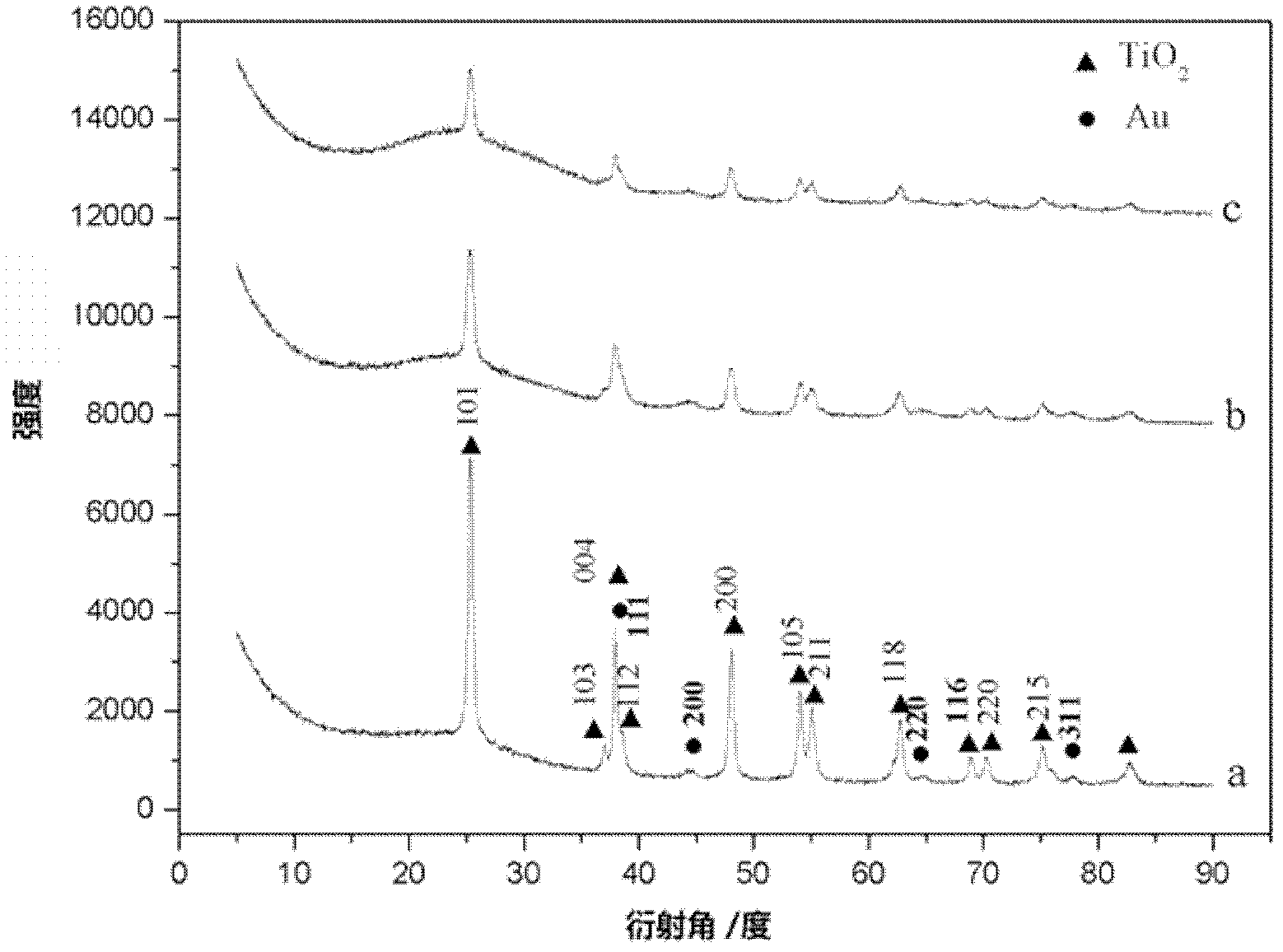

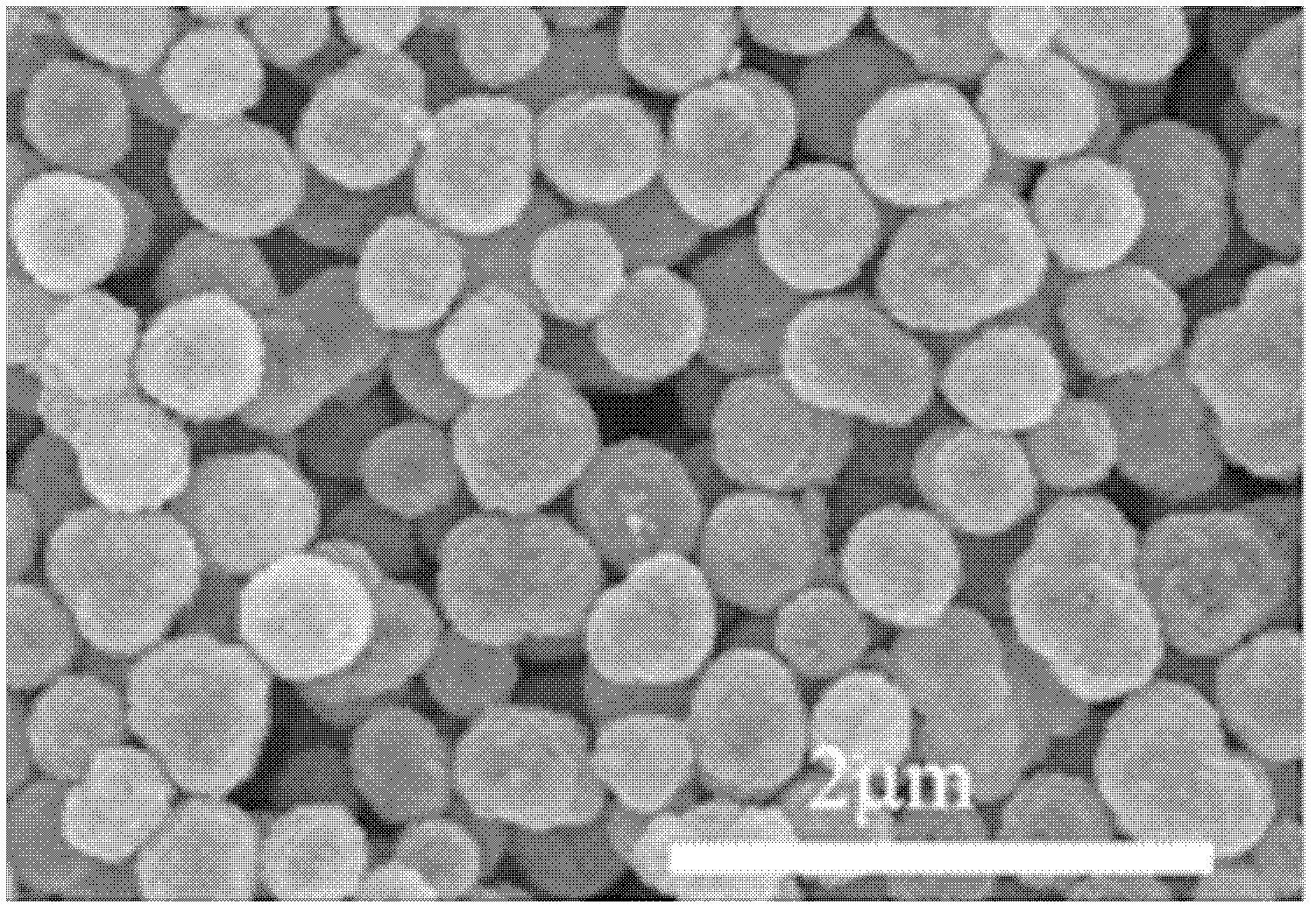

[0051] Carry out according to the method in embodiment 1, difference is step 2) TiF 4 The amount of solution used is such that TiF 4 The molar amount added is 100 times the molar amount of Au nanoparticles in the Au colloid solution. Finally, the hollow core-shell structure AuTiO 2 nanocomposites. Its X-ray powder diffraction pattern ( figure 2 In b) shows AuTiO 2 Nanocomposites do contain Au and TiO 2 The characteristic diffraction peak; Scanning electron micrograph ( Figure 4 ) shows that the composite material presents a spherical morphology; transmission electron micrographs ( Figure 7 ) and high-angle dark-field scanning transmission electron microscopy ( Figure 10 ) shows that the edge of the sphere is darker, and the inner color of the sphere is lighter, that is, the interior is a cavity, indicating that the composite material is a hollow structure, and Au nanoparticles are coated on the hollow TiO 2 inside the cavity, through Figure 10 As shown, the shell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com