Lignin-based porous carbon material and preparation method thereof

A porous carbon material and lignin-based technology, which is applied in the treatment of heavy metal-polluted wastewater, porous carbon materials and its preparation, can solve problems such as equipment environmental damage, heavy metal pollution, and development restrictions, and achieve mitigation of impact and strong adsorption , good operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

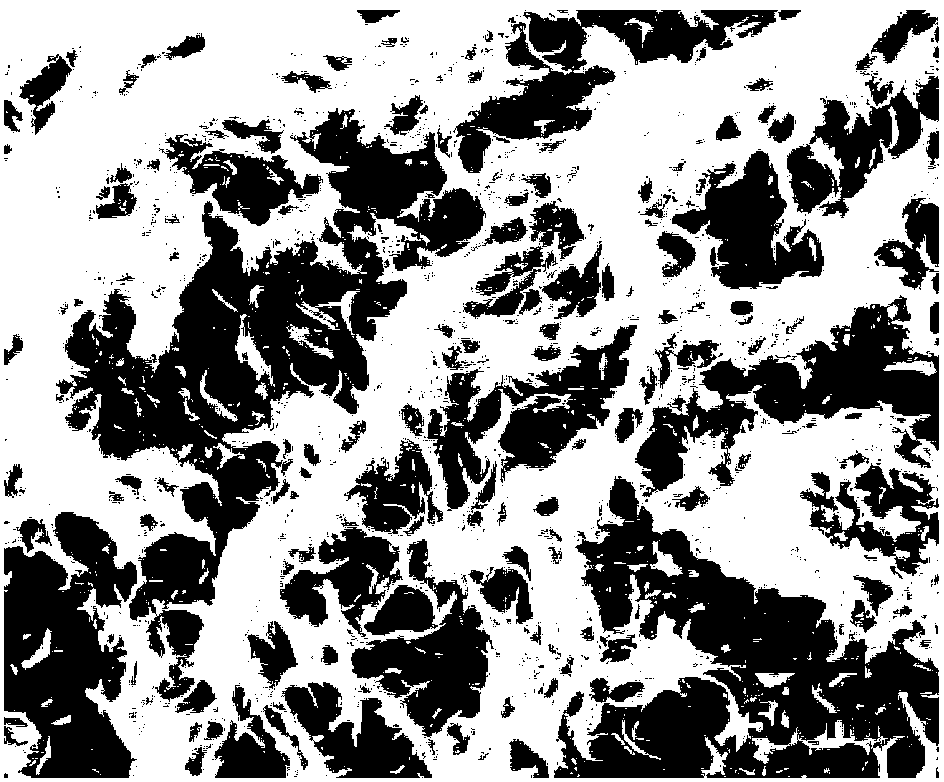

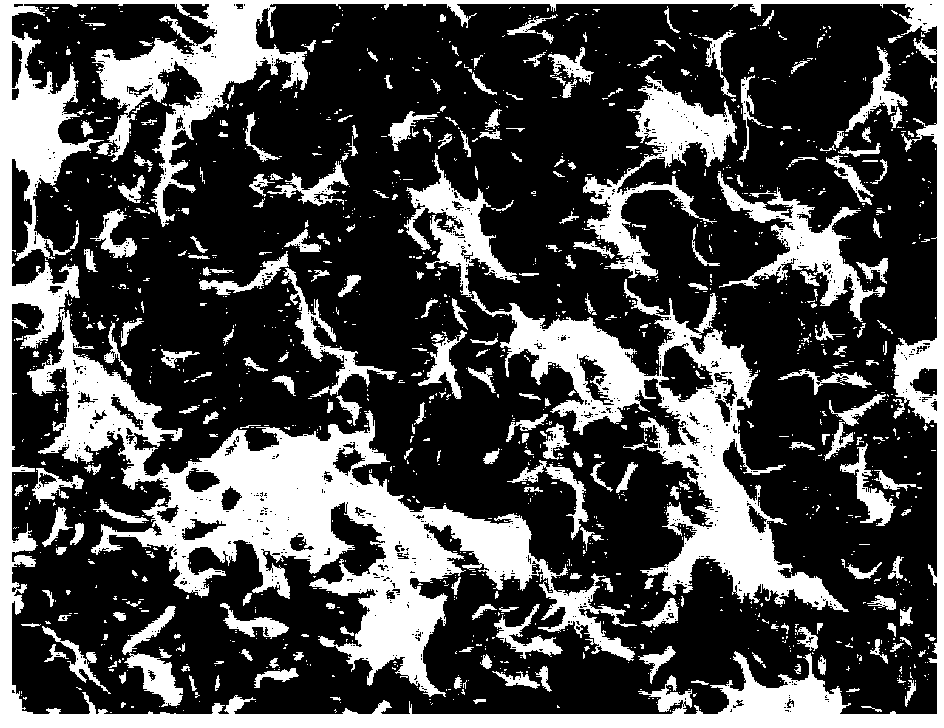

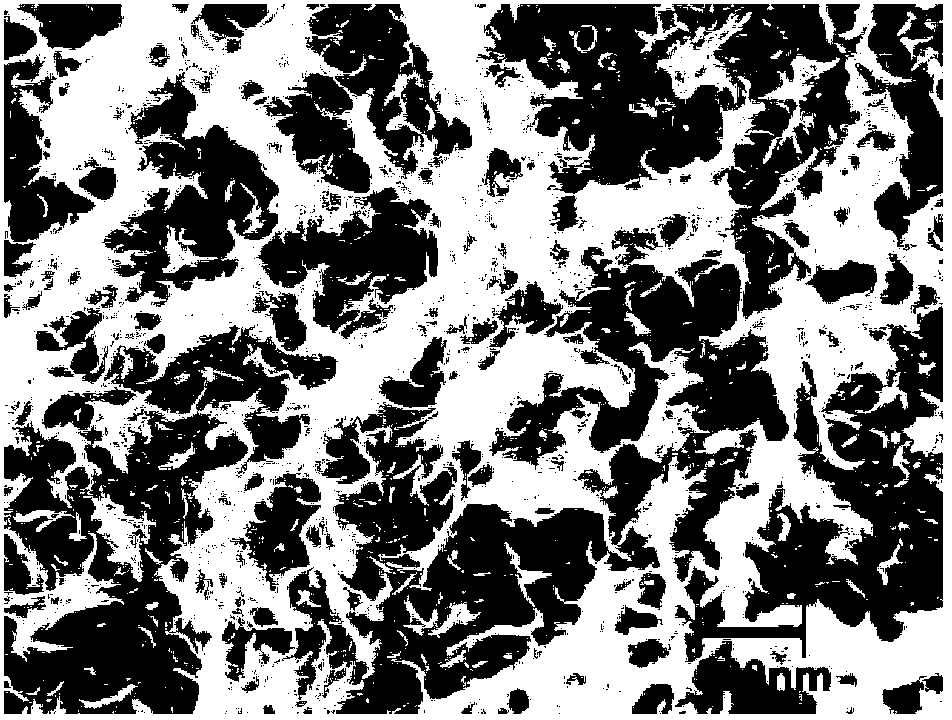

Embodiment 1

[0026] Take 500g of bagasse, dry it in an oven at 80°C for 12 hours, put it into a ball mill and grind it to 60 mesh, add 5000ml of ethanol, put it in an autoclave and cook it at 180°C for 6 hours, filter to remove insoluble matter, and evaporate the filtrate After concentration and drying, ethanol lignin can be obtained; take 80g of ethanol lignin and put it into a muffle furnace for pre-carbonization treatment to obtain a carbonized intermediate. In the ceramic tube of the tube furnace, an inert atmosphere of argon is introduced as a protective gas. After the air is exhausted, the temperature is raised to 850°C at a heating rate of 15°C / min, and the secondary carbonization is performed for 4 hours. After the reaction is over, keep the argon flowing continuously, let it cool to ambient temperature, wash the product twice with 30% hydrochloric acid, then wash five times with distilled water, and then dry at 100°C for 16 hours to obtain a black powdery woody Plain-based porous ...

Embodiment 2

[0029] Take 300g of bagasse, dry it in an oven at 90°C for 18 hours, put it into a ball mill and pulverize it, take the fraction below 60 mesh, add 4000ml of ethanol, put it in an autoclave and cook it at 200°C for 5 hours, filter to remove insoluble matter , take the filtrate to evaporate, concentrate and dry to obtain ethanol lignin; take 50g of ethanol lignin, put it into a muffle furnace for pre-carbonization treatment to obtain a carbonized intermediate, the pre-carbonization treatment temperature is 250°C, and the time is 180min; take the carbonized intermediate Place it in a ceramic tube of a high-temperature tube furnace, and pass in an inert atmosphere of nitrogen as a protective gas. After the air is exhausted, the temperature is raised to 950°C at a heating rate of 10°C / min, and the secondary carbonization treatment is performed for 3 hours. After the reaction is finished, keep nitrogen flowing continuously, let it cool to ambient temperature, wash the product with 3...

Embodiment 3

[0032] Take 800ml of papermaking black liquor, add sulfuric acid, adjust its pH value to 2.0~2.5, wait for the precipitation of the precipitate, collect the precipitate, filter, wash repeatedly with distilled water until the pH is neutral, put it in an oven and dry at 100°C to obtain Alkali lignin; take 10g of the obtained alkali lignin and put it into a muffle furnace for pre-carbonization treatment to obtain a carbonized intermediate. The pre-carbonization treatment temperature is 280°C and the time is 160min; take the carbonized intermediate and place it in a high-temperature tube furnace ceramic tube , into an inert atmosphere of argon as a protective gas, after the air is exhausted, the temperature is raised to 1000°C at a rate of 20°C / min, and the secondary carbonization treatment is performed for 2 hours. After the reaction is finished, keep the argon flowing continuously, let it cool to ambient temperature, wash the product twice with 35% dilute sulfuric acid, wash thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com