Desalting device and process through high-voltage capacitor adsorption

A high-voltage capacitor and process technology, which is applied in the field of high-voltage capacitor adsorption and desalination devices, can solve problems such as easy electrolysis of the solution, high requirements for electrode materials, and complex device structures, and achieve corrosion prevention, low requirements for electrode materials, and simple structure and devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

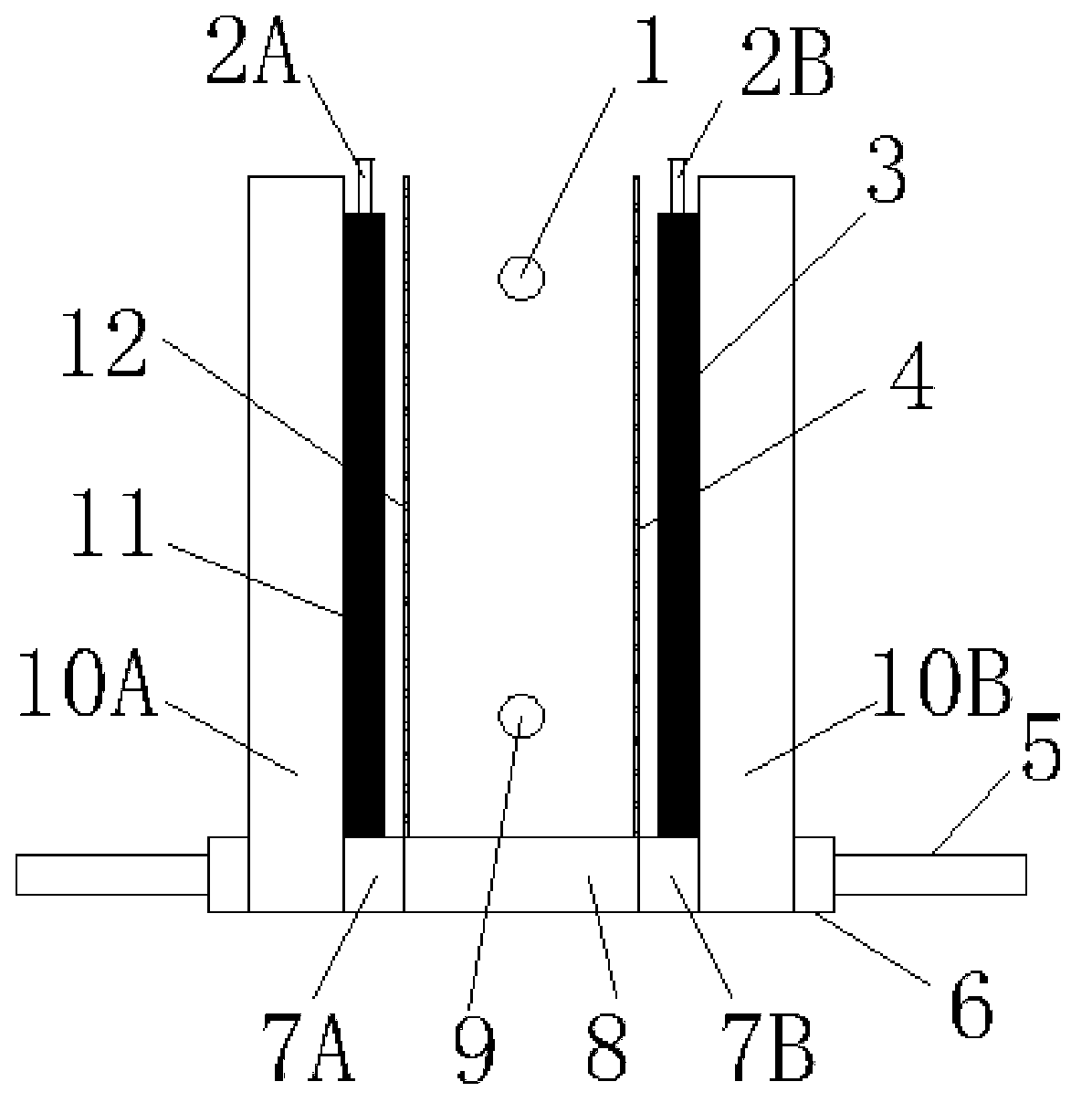

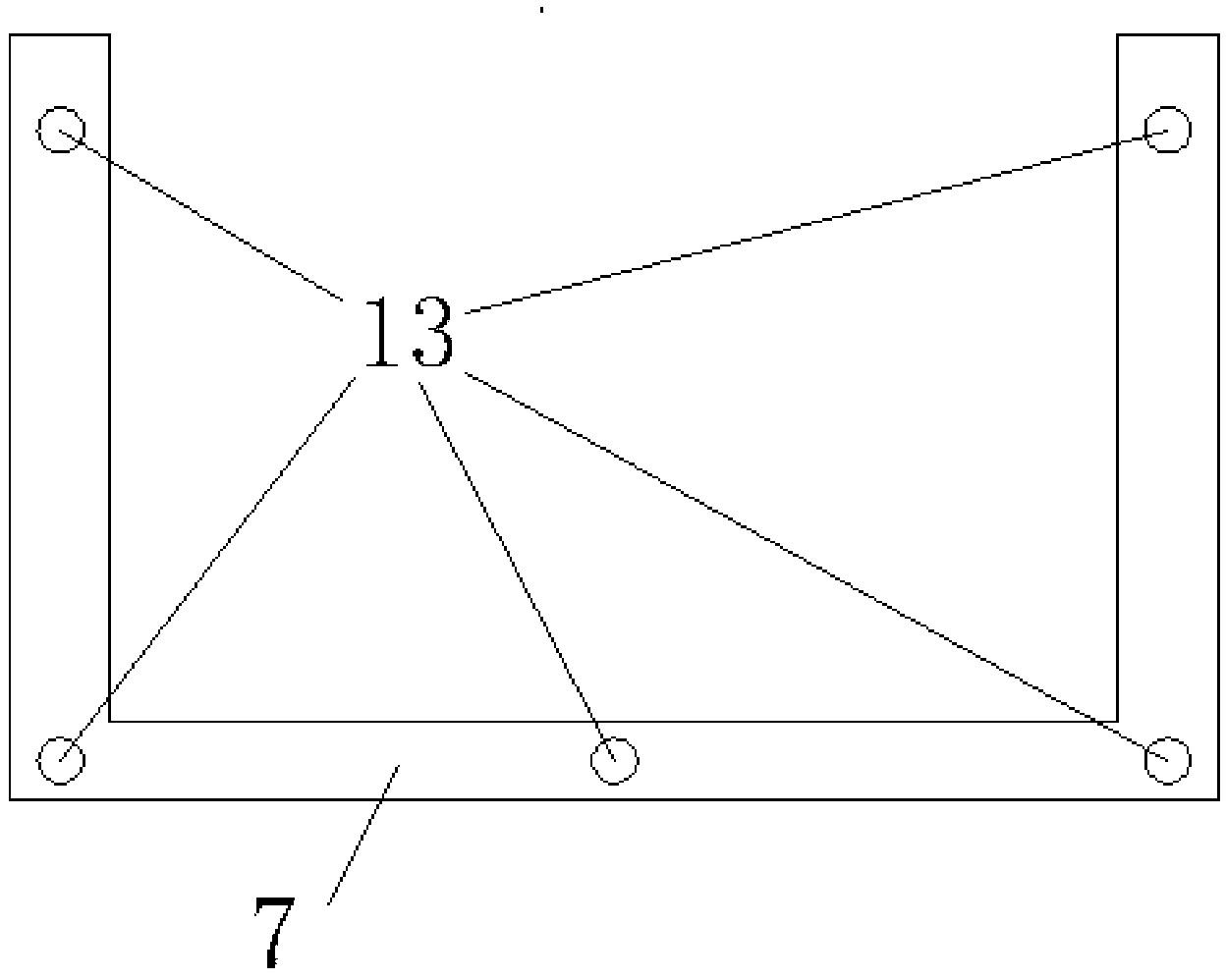

[0023] Such as figure 1 Shown: plexiglass is used as the material of the side wall and each plate, the whole device is a cuboid structure, and the reaction chamber is in accordance with the first side wall 10A, the first detachable plate 7A, the movable plate 8, the second detachable plate 7B and the first detachable plate After the two side walls 10B are arranged in sequence, the long iron rod 5 with threads passes through the small holes 13 provided in the corresponding positions to connect (such as figure 2 ); between the first side wall 10A and the first detachable plate 7A, between the second detachable plate 7B and the second side wall 10B, an anion membrane 12 and a cation membrane 4 are respectively embedded, and both ends are fixed with supporting nuts 6 , the size of the anion and cation membrane matches the reaction chamber, and the flow channel is formed between the anion membrane 12 and the cation membrane 4; the inside of the reaction chamber is close to the rel...

Embodiment 2

[0025]The structure of the device is as in Example 1, wherein the electrode plate is made of graphite electrode, and the electrode plate with a size of 55 mm × 80 mm is selected according to the size of the reaction chamber. The thickness of the electrode plate is 2 mm, and the distance between the electrode plates is 20 mm. The thickness is 0.5mm, the membrane pore diameter is 4μm, the gap between the anion membrane and the anode plate, and between the cation membrane and the cathode plate is 2mm, the water inlet and water outlet aperture is 5mm, and the small hole diameter is 3mm, and the conductivity meter is used to measure the salt The conductivity of the solution, using the conductivity value to characterize the concentration of the solution, prepare a 500mg / L NaCl solution as a simulated saline wastewater, add it to the reaction chamber, close the water inlet and outlet, adjust the voltage to 60V, carry out static adsorption reaction, and measure the conductivity of the r...

Embodiment 3

[0027] The structure is as in Example 1. The electrode plate is made of stainless steel electrode. The size of the electrode plate is 80mm×100mm. The thickness of the electrode is 5mm. 6μm, the gap between the anion membrane and the anode plate, and between the cation membrane and the cathode plate is 5mm, the aperture of the water inlet and outlet is 5mm, and the aperture of the small hole is 3mm. Use a conductivity meter to measure the conductivity of the salt solution. Use the conductivity value To characterize the solution concentration, the temperature is 25°C and the concentration is 80mg / LCaCl 2 The solution (conductivity value is about 200μS / cm) is used as the influent water, which is sent into the reaction chamber by the peristaltic pump. The flow rate of the solution is adjusted to 72m / s, and the voltage is 20V. The conductivity value of the effluent water is measured every 15min. The lowest, stop the water inlet for backwashing after 1 hour of reaction, and proceed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com