Adhesive sheet

A technology of adhesive sheets and adhesive layers, applied in the direction of adhesive types, adhesives, film/sheet adhesives, etc., can solve problems such as poor stress relaxation, micro-dispersion state damage, and poor peeling, and achieve good Effects of stress relaxation, good initial adhesion, and good adhesion over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

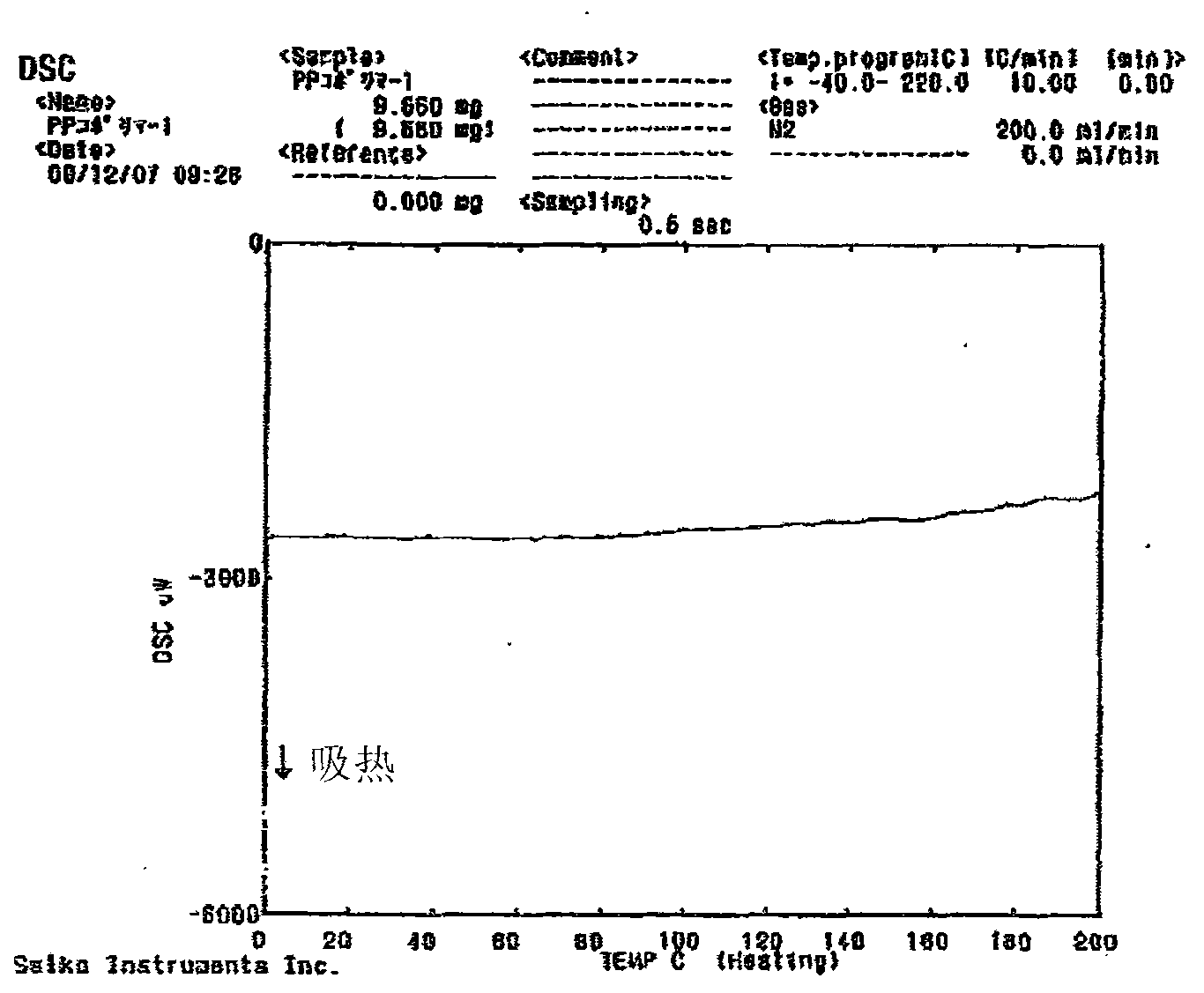

Embodiment 1

[0094] As a material for forming the adhesive layer, 17% by weight of hydrogenated resin was added to a mixture composed of 80% by weight of propylene-based copolymer (1) and 20% by weight of ethylene / vinyl acetate copolymer (manufactured by Tosoh Corporation, Ultracene 633). An adhesive composition based on petroleum resin (manufactured by Arakawa Chemical Co., Ltd., Alcon P-125), as a material for forming a black layer of the base material intermediate layer, 1% by weight of carbon black (manufactured by Mitsubishi Chemical, carbon black "# 45") low-density polyethylene (manufactured by Tosoh Corporation, Petrothene 172), and the above-mentioned low-density polyethylene (manufactured by Dainichi Seika Co., Ltd., HCM2035W) added with 20% by weight of white pigment was used as a material for forming the white layer of the surface layer of the substrate. Polyethylene, each material is co-extruded by blow molding to obtain a surface protection sheet (1).

[0095] The thickness o...

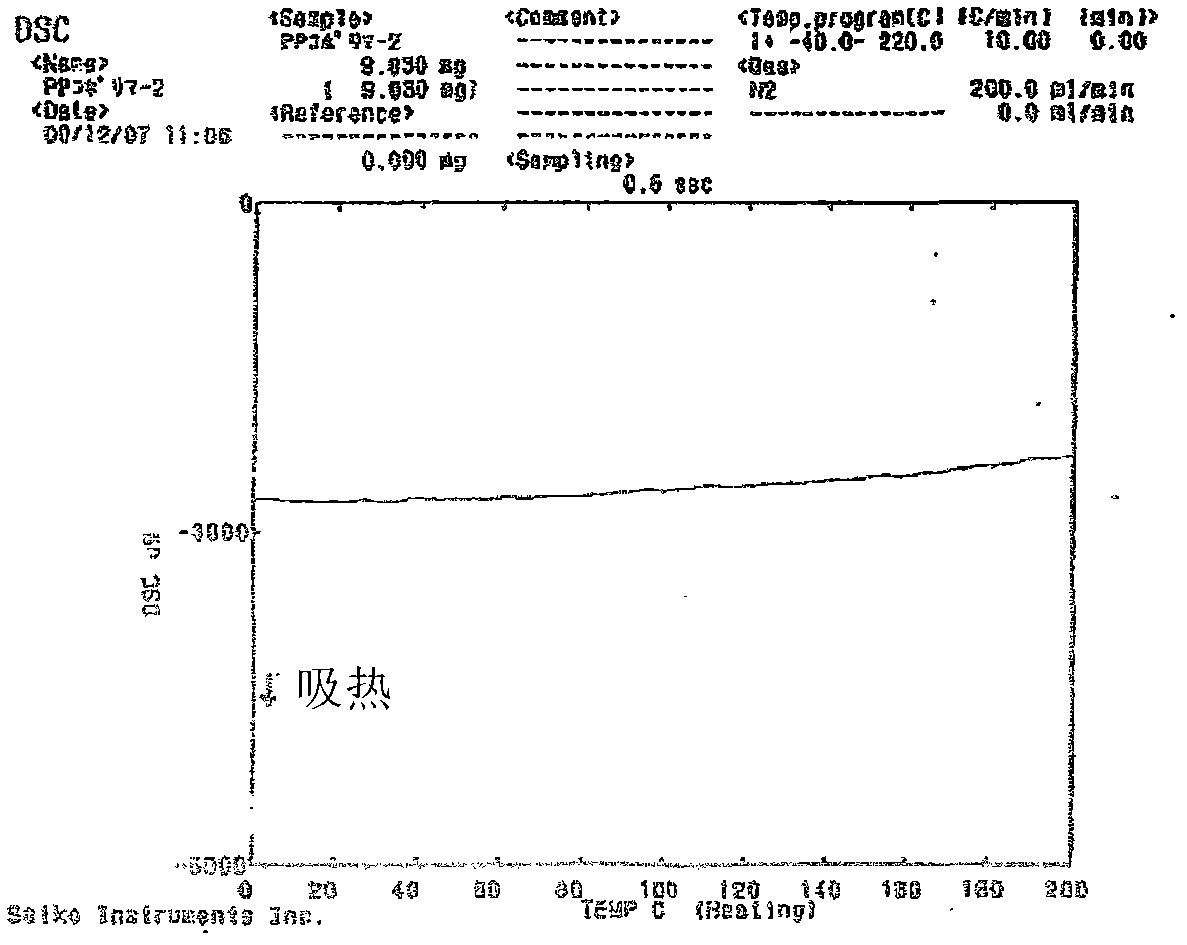

Embodiment 2

[0097] In Example 1, an adhesive composed of 80% by weight of the propylene-based copolymer (1) and 20% by weight of linear low-density polyethylene (manufactured by Idemitsu Petrochemical Co., Ltd., Idemitsu LL1014G) was used as the forming material of the adhesive layer. Except for the composition, it carried out similarly to Example 1, and obtained the surface protection sheet (2).

[0098] The thickness of the surface protection sheet (2) is white-colored layer / black-colored layer / adhesive layer=25 μm / 25 μm / 15 μm.

Embodiment 3

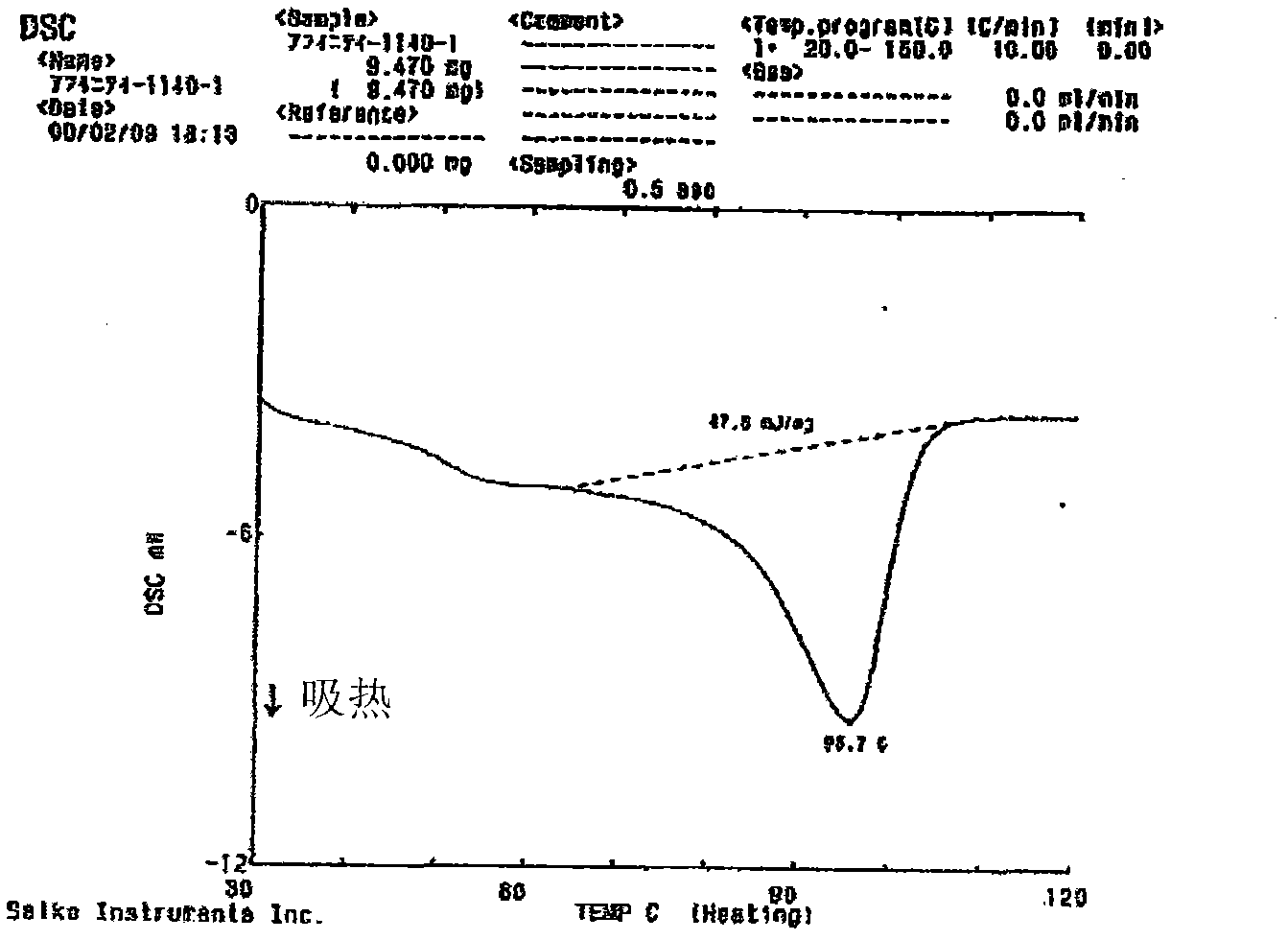

[0100] As a material for forming the adhesive layer, 9% by weight of hydrogenated terpene was added to a mixture composed of 90% by weight of the propylene-based copolymer (1) and 10% by weight of random polypropylene (manufactured by Idemitsu Petrochemical Co., Ltd., F-744NP). An adhesive composition of vinyl resin (manufactured by YASUHARA CHEMICAL, Clearon P-105) was used as a material for forming the white layer of the surface layer of the base material, with the addition of 0.7 The material of weight % fatty acid amide, 20 weight % white pigment (manufactured by Dainichi Seika Co., Ltd., HCM2035W) is used as the material of the black color layer forming the base material intermediate layer. 0.3% by weight of ultraviolet absorber (manufactured by Ciba Specialty Chemicals, Tinuvin), 0.22% by weight of light stabilizer (manufactured by Ciba Specialty Chemicals, Chimassorb), 1% by weight of carbon black (manufactured by Mitsubishi Chemicals, carbon black "#45") Each material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com