Preparation method of lithium ferrous silicate composite material

A technology of lithium ferrosilicate and composite materials, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of uneven particle size and complex process of lithium ferrosilicate composite materials, and achieve controllable morphology and cycle. High performance, process improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of lithium ferrous silicate composite material of the present invention, specifically implement according to the following steps:

[0023] Step 1, sequentially dissolving the lithium source compound, iron source compound, silicon source compound and surfactant in the solvent, the molar ratio of lithium in the lithium source compound, iron in the iron source compound, and silicon in the silicon source compound is 1.95-2.1: 1:1; the mass ratio of surfactant to lithium source compound is 0 to 3:1, the molar ratio of solvent to lithium source compound is 100 to 500:1, and then the pH is adjusted to 2 to 6 with organic acid, and then In the reaction kettle, react in low temperature water at 150-200°C for 1-24 hours, wash with water, filter, and finally obtain the precursor by spray drying;

[0024] In step 2, the precursor obtained in step 1 is mixed with the carbon source compound and then ball milled. The quality of the carbon source compound is 1 to...

Embodiment 1

[0034] Step 1, sequentially dissolve 0.01mol of lithium carbonate, 0.02mol of ferrous sulfate, 0.02mol of tetraethyl orthosilicate and 2g of polyethylene glycol in 60ml of deionized water, then adjust the pH to 4 with citric acid, and then React in low temperature water at 180°C for 12 hours, wash with water, filter, and finally spray dry to obtain the precursor;

[0035]Step 2, mix the precursor obtained in step 1 with 0.48g of glucose, ball mill for 24 hours, then in an inert atmosphere, first keep it at 450°C for 2h, then keep it at a high temperature of 750°C for 10h, and after cooling, you can get lithium ferrous silicate composite Material.

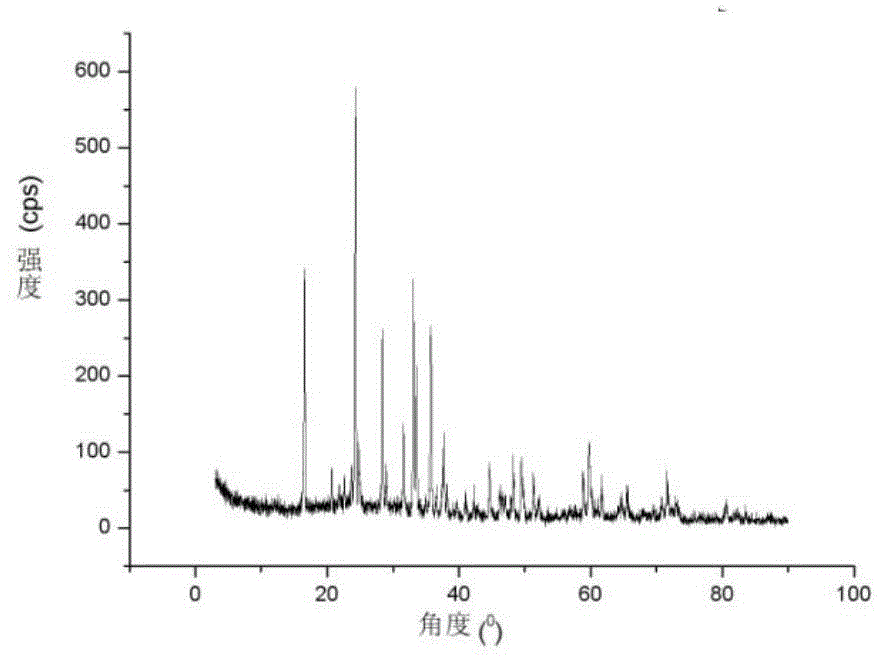

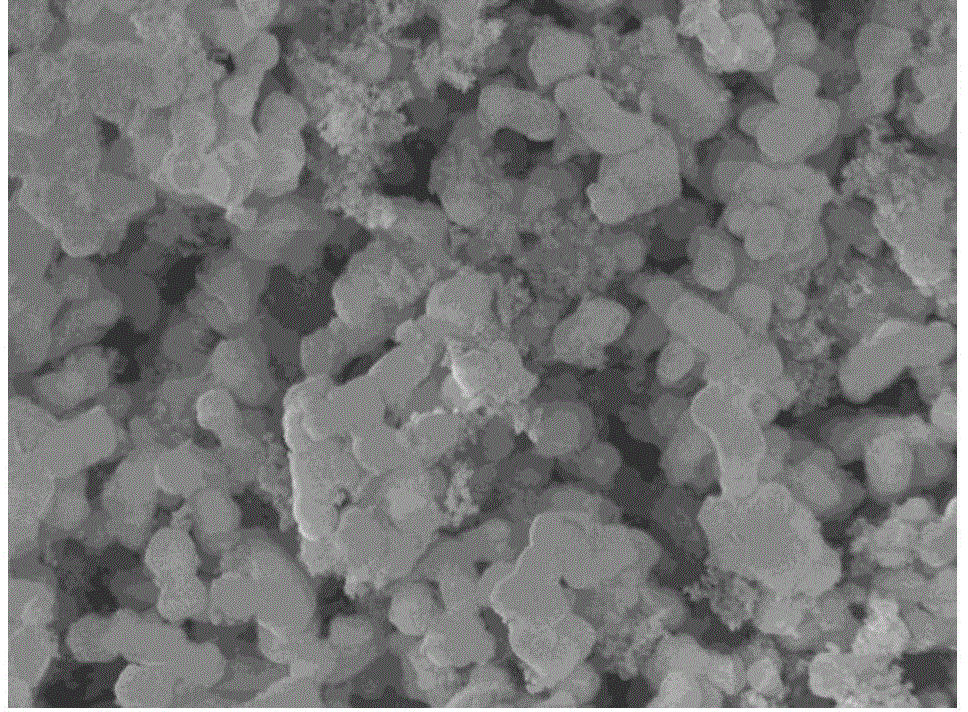

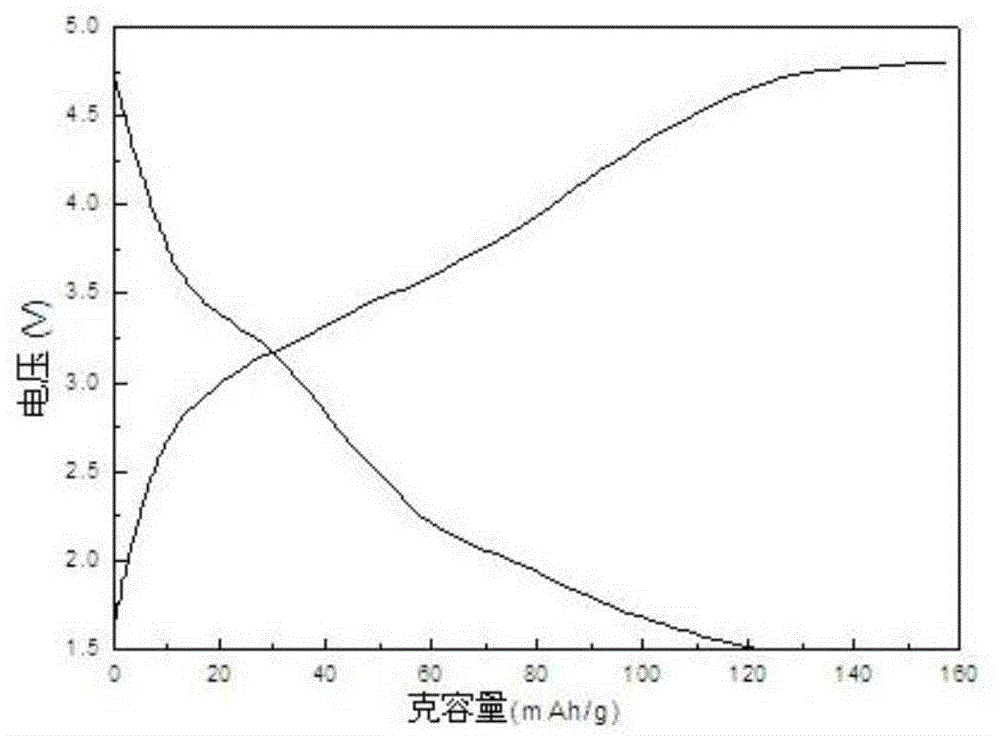

[0036] figure 1 It is the X-ray diffraction pattern of the lithium ferrous silicate composite material prepared in Example 1 of the present invention, from figure 1 As can be seen, figure 1 The main peak is the diffraction peak of the lithium ferrous silicate composite material, indicating that the lithium ferrous silicate compos...

Embodiment 2

[0040] Step 1, sequentially dissolve 0.039 lithium acetate, 0.02mol ferrous sulfate, 0.02mol sodium silicate in a mixture of 30ml ethanol and 40ml acetone, then use ascorbic acid to adjust the pH to 2, and then carry out low temperature in the reaction kettle at 150°C After reacting in water for 24 hours, wash with water, filter, and finally spray dry to obtain the precursor;

[0041] Step 2, mix the precursor obtained in step 1 with 0.0322g of conductive graphite and ball mill for 24 hours, then in an inert atmosphere, first keep it at 300°C for 6h, then keep it at a high temperature of 600°C for 24h, after cooling, you can get lithium ferrous silicate composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com