Liquid active magnesium-cuprous chloride paper battery and preparation method thereof

A technology of cuprous chloride paper and liquid activation, which is applied in the direction of dry batteries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

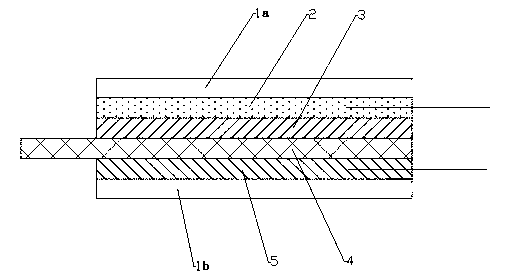

Image

Examples

Embodiment 1

[0039] Example 1. Fabrication of liquid-activated magnesium-cuprous chloride paper batteries.

[0040] (1) Passivation treatment of magnesium anode. Soak 0.1mm thick metal magnesium foil in 0.05M stannate solution for 5 minutes to form a passivation film.

[0041] (2) Preparation of electrolyte. Prepare Mg(ClO 4 ) 2 Electrolyte with a concentration of 0.4M and a quaternary ammonium salt concentration of 0.06M.

[0042](3) Treatment of fiber paper. Immerse the filter paper in the above mixed electrolyte for 2-3 minutes, take out and drain the excess drip, and dry it at 40-50°C for later use.

[0043] (4) Preparation of cuprous chloride mixed powder. The method is to mix according to the ratio of cuprous chloride: graphite: carbon nanotube: zeolite = 90:5:5:0.1, and obtain CuCl mixed powder through ball milling.

[0044] (5) Preparation and coating of CuCl active slurry. The method is to weigh a certain amount of cuprous chloride mixed powder, add deionized water to pre...

Embodiment 2

[0047] Example 2. Fabrication of liquid-activated magnesium-cuprous chloride paper batteries.

[0048] (1) Passivation treatment of magnesium anode. The method is to immerse a magnesium alloy with a thickness of about 0.2mm in a 0.05M vanadate solution for 3 minutes to form a passivation film.

[0049] (2) Preparation of electrolyte. Prepare MgSO 4 An electrolyte with a concentration of 1.0M and a stannate concentration of 0.03M.

[0050] (3) Treatment of fiber paper. The method is to soak the quick-absorbing paper in the above-mentioned electrolyte for 2-3 minutes, take out and drain the excess dripping liquid, and dry it at 40-50°C for later use.

[0051] (4) The preparation of CuCl mixed powder, its method is to press CuCl: carbon nanotube: V 2 o 5 =90:10:0.05 ratio mixing, through ball milling to get CuCl mixed powder.

[0052] (5) Preparation and coating of CuCl active slurry. The method is to weigh a certain amount of CuCl mixed powder, add deionized water to pre...

Embodiment 3

[0055] Example 3. Fabrication of liquid-activated magnesium-cuprous chloride paper batteries.

[0056] (1) Passivation treatment of magnesium negative electrode, the method is to immerse a 0.1mm thick magnesium foil in a 0.1M phosphate solution for 5 minutes to form a passivation film.

[0057] (2) Preparation of electrolyte, preparation of MgBr 2 An electrolyte with a concentration of 0.2M and a chromate concentration of 0.02M.

[0058] (3) Treatment of fiber paper, the method is to immerse the filter paper in the above electrolyte solution for 5 minutes, take out and drain the excess dripping liquid, and dry it at 40~50°C for later use.

[0059] (4) Preparation of CuCl mixed powder, the method is to mix according to the ratio of CuCl: carbon black: MgO=85:15:0.1, and obtain CuCl mixed powder by ball milling.

[0060] (5) Preparation and coating of CuCl active slurry. The method is to weigh a certain amount of CuCl mixed powder, add deionized water to prepare a slurry, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com