Reinforced cement grinding aid and preparation method thereof

A cement grinding aid and enhanced technology, which is applied in the field of enhanced cement grinding aid and its preparation, can solve the problems of inconspicuous effect and high production cost, and achieve the effect of low price, low cost and sufficient source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]10 parts by weight of polystyrene foam plastics are pre-dissolved in 30 parts by weight of organic solvent hexane oxide, add the catalyst phosphorus pentoxide of 0.05 parts by weight, add the concentrated sulfuric acid of 20 parts by weight of 95% dropwise to the reactor, at 60 After reacting at ℃ for 4 hours, add 50 parts by weight of water, stir and separate the hexane oxide, then neutralize the remaining sulfuric acid with waste alumina, filter to remove impurities and unreacted waste alumina, and adjust with 20% NaOH solution Solution pH value is 7, obtains the mixed solution of SPS and aluminum sulfate;

[0021] Take 26 parts by weight of the above-mentioned mixed solution of SPS and aluminum sulfate, add 28.5 parts by weight of water, 20 parts by weight of diethanol monoisopropanolamine (DEIPA), 5 parts by weight of ethylene glycol, 10 parts by weight of diethylene glycol, molasses 10 parts by weight and 0.5 parts by weight of tributyl phosphate were mixed and stir...

Embodiment 2

[0024] Dissolve 10 parts by weight of polystyrene foam in advance in 100 parts by weight of organic solvent 1,2-dichloroethane, add 0.2 parts by weight of catalyst silver sulfate, and drop 25 parts by weight of 97% concentrated sulfuric acid into the reactor, After reacting at 40°C for 8 hours, add 65 parts by weight of water, stir and separate 1,2-dichloroethane, then use bauxite to neutralize the remaining sulfuric acid, filter to remove impurities and unreacted bauxite, and use 40% NaOH solution adjusts the pH value of the solution to 7 to obtain a mixed solution of SPS and aluminum sulfate;

[0025] Take 52.5 parts by weight of the above-mentioned mixed solution of SPS and aluminum sulfate, add 20.2 parts by weight of water, 3 parts by weight of N,N,N',N'-tetrakis(2-hydroxyethyl)ethylenediamine (THEEA), diethanol 7 parts by weight of monoisopropanolamine (DEIPA), 7 parts by weight of diethylene glycol, 5 parts by weight of corn syrup, 5 parts by weight of sucrose, and 0.3 ...

Embodiment 3

[0028] Take 45 parts by weight of the mixed solution of SPS and aluminum sulfate prepared in Example 2, add 30 parts by weight of water, N,N,N',N'-tetrakis(2-hydroxyethyl)ethylenediamine (THEEA) 5 Parts by weight, 2.5 parts by weight of methyldiethanolamine (MEDA), 5 parts by weight of propylene glycol, 5 parts by weight of diethylene glycol, 5 parts by weight of sucrose, 2.3 parts by weight of sodium gluconate, and 0.2 parts by weight of tributyl phosphate are mixed, stirred, An enhanced cement grinding aid is obtained.

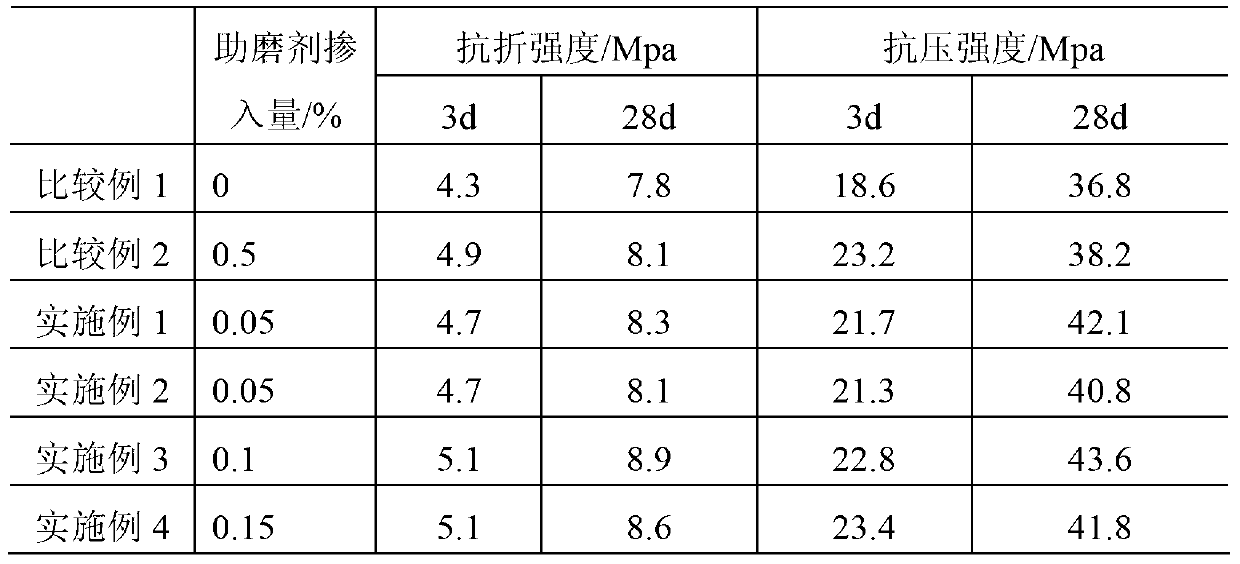

[0029] Add 0.1% of the enhanced cement grinding aid prepared in this example to the fly ash Portland cement with a fly ash content of 30%, and measure its enhancement effect. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com