Method for recycling vanadium from vanadium-containing electrolysis aluminum slag ash

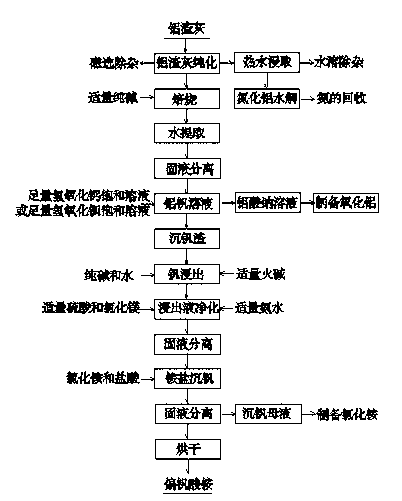

A technology of aluminum slag ash and slag ash, which is applied in the field of chemical beneficiation and secondary resource utilization, can solve the problems of inefficient separation of aluminum and vanadium, and achieve good comprehensive recycling, strong adaptability, and less waste gas and waste solids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. A certain aluminum slag ash, the main components of which are shown in Table 1. Weigh an appropriate amount of the aluminum slag ash and add it to a round bottom flask, add 1:4 water, shake it up and heat it on a temperature-controlled electric furnace. The hydrolysis of aluminum and aluminum carbide releases a large amount of ammonia and methane. The ammonia can be absorbed with 33% dilute sulfuric acid to prepare ammonium sulfate or absorbed with water to prepare ammonia water. The soluble salt in the aluminum ash is dissolved in hot water, and after the hydrolysis of aluminum nitride and aluminum carbide is completed, it is filtered, and the solid is purified aluminum slag ash.

[0054] 2. Add a certain amount of sodium carbonate to the purified aluminum slag ash. The mass ratio of sodium carbonate to spent catalyst (Al2O3+V2O5) is 0.8:1. Mix the two evenly and roast them in a muffle furnace at high temperature , the temperature is 900°C, and the time is 40min;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com