Improve anode material of lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the inability to meet the requirements of commercial applications, improve overcharge performance and safety performance, increase battery capacity, and avoid direct contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 0.4311g of lithium carbonate, 2.1887g of aluminum nitrate, 0.16g of titanium dioxide, 0.29g of magnesium oxide and 0.7698g of silicon dioxide in a beaker, add 400ml of deionized water, and stir evenly at a stirring speed of 80Hz. Weigh 100g of lithium cobaltate, add it into a beaker and continue to stir, after mixing evenly, soak and evaporate to dryness to remove water, and dry at 150°C for 24h. The obtained powder was roasted in a muffle furnace, and the roasting system was as follows: heating up to 700 °C at a rate of 10 °C / min, holding the temperature for 10 h, cooling with the furnace, and sieving.

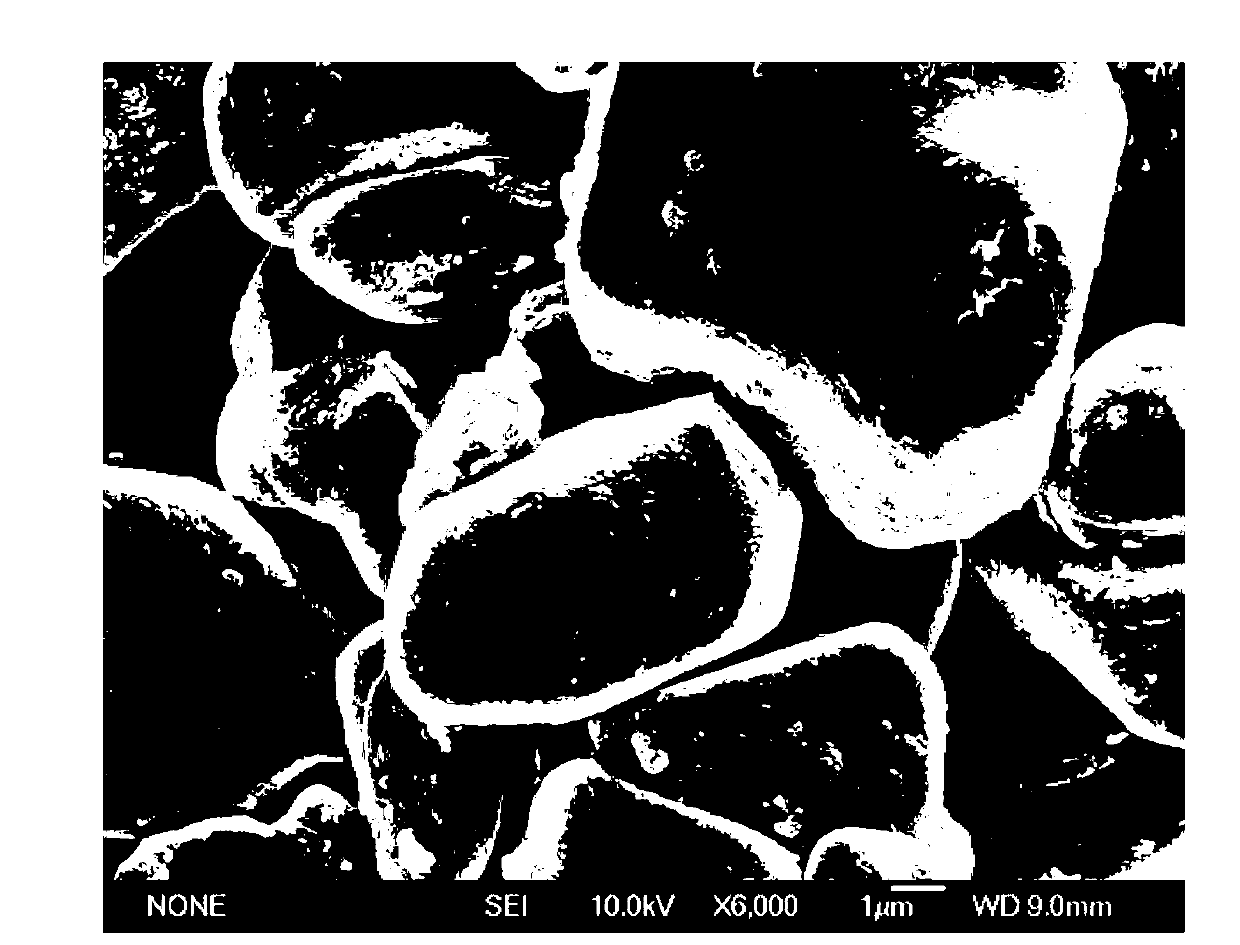

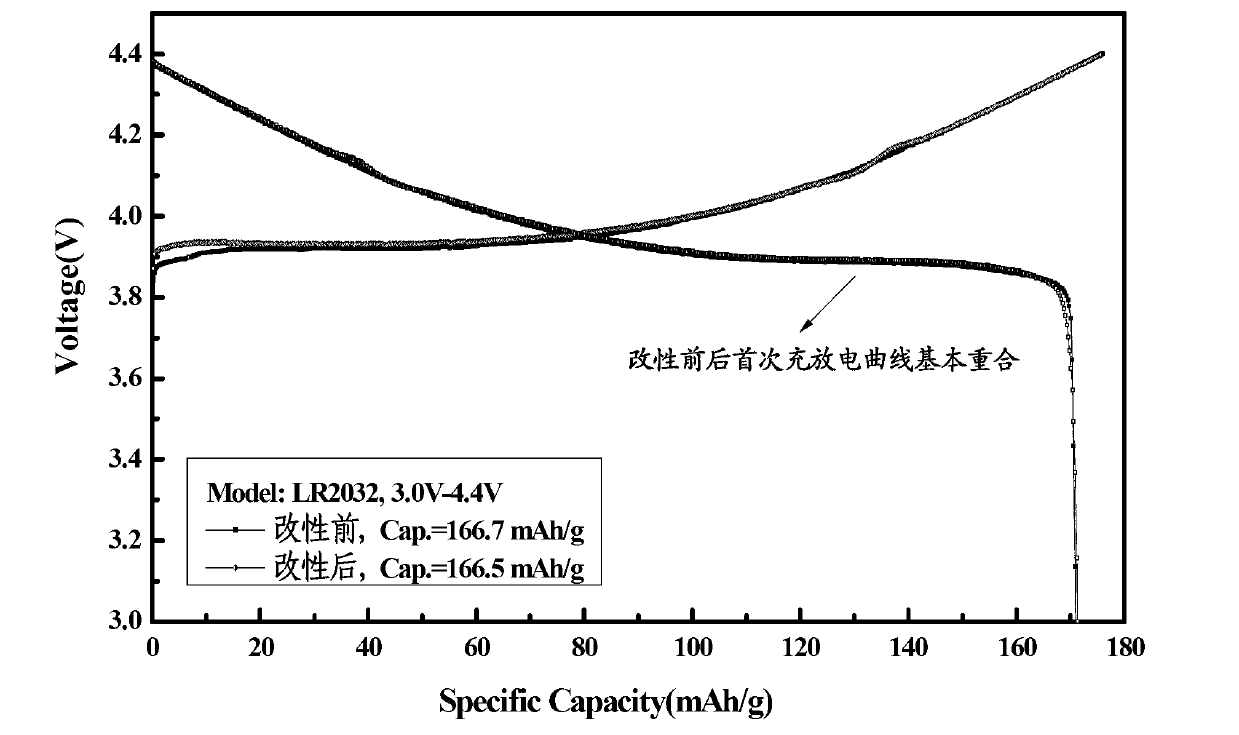

[0037] The physical and chemical analysis of the final product shows that the surface of the raw material lithium cobaltate is coated with a solid electrolyte layer with an average thickness of about 50nm, and the total coating amount is: 1.3% (mass fraction). As shown in Figure 1, the material modified Its microscopic morphology did not change before and after. T...

Embodiment 2

[0041]Put 5.5103g of n-butyl titanate, 2.154g of magnesium nitrate, 1.167g of silicon dioxide and 0.4809g of lithium metasilicate into a beaker, add 700ml of deionized water, under the condition that the temperature of the water bath is 80°C and the stirring speed is 100Hz Next, stir well. Weigh 150g of lithium cobaltate, add it into a beaker and continue stirring for 2h, filter with suction, and dry the filter cake for 24h at 120°C. Put the obtained powder in a furnace for roasting, the roasting system is: 5°C / min to 900°C, keep warm for 5h, cool with the furnace, and sieve.

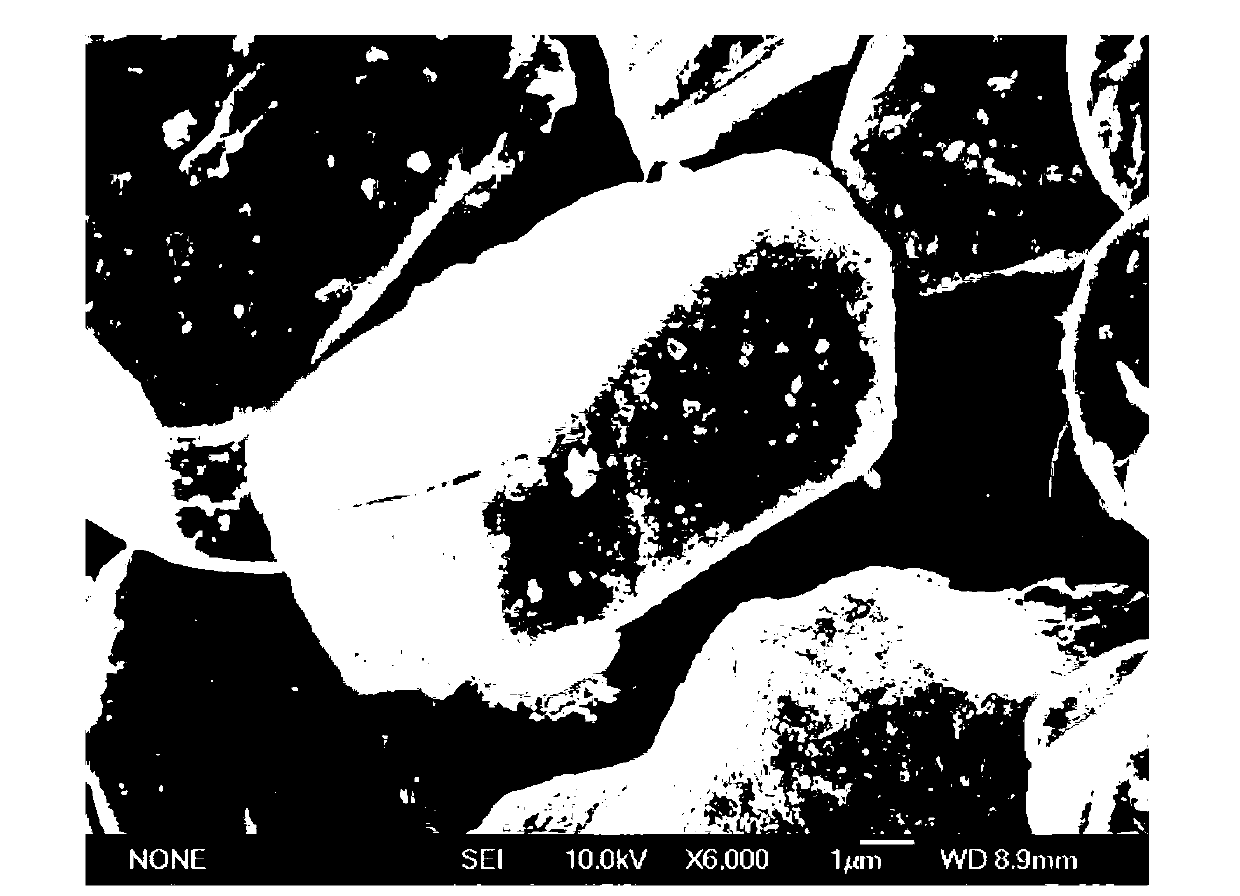

[0042] Through physical and chemical analysis, it is known that the surface of the raw material lithium cobaltate is coated with a solid electrolyte layer with an average thickness of about 120nm, and the total coating amount is: 3.0% (mass fraction). No change. Pack the modified material into a button battery. The electrode ratio in the button battery is: active material: SP:PVDF=91:4:5, Clgard2300 d...

Embodiment 3

[0044] Put 1.0560g of silicon dioxide, 0.7219g of zirconia, 0.6853g of ammonium vanadate and 0.2950g of lithium hydroxide in a beaker, add 700ml of deionized water, and set the temperature of the water bath at 60°C and the stirring speed at 100Hz. Stir well. Weigh 100g of lithium manganate, add it into a beaker and continue to stir for 4h, filter with suction, and dry the filter cake at 120°C for 36h. The obtained powder is roasted in a bell-type furnace, and the roasting system is as follows: 3°C / min to 1000°C, heat preservation for 2h, cooling with the furnace, and sieving.

[0045] Through physical and chemical analysis, it is known that the surface of the raw material lithium manganate is coated with a solid electrolyte layer with an average thickness of about 100nm, and the total coating amount is: 1.9% (mass fraction). The modified material is packed into a button battery. The electrode ratio in the button battery is: active material: SP: PVDF = 91: 4: 5, Clgard2300 dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com