Oxidative desulfurization amphiphilic catalyst, and preparation method and applications thereof

An oxidative desulfurization and amphiphilic technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, refining with oxygenated compounds, etc., can solve the problems of organic acid separation, poor catalytic effect, small contact surface, etc., and achieve regeneration Convenience, good stability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

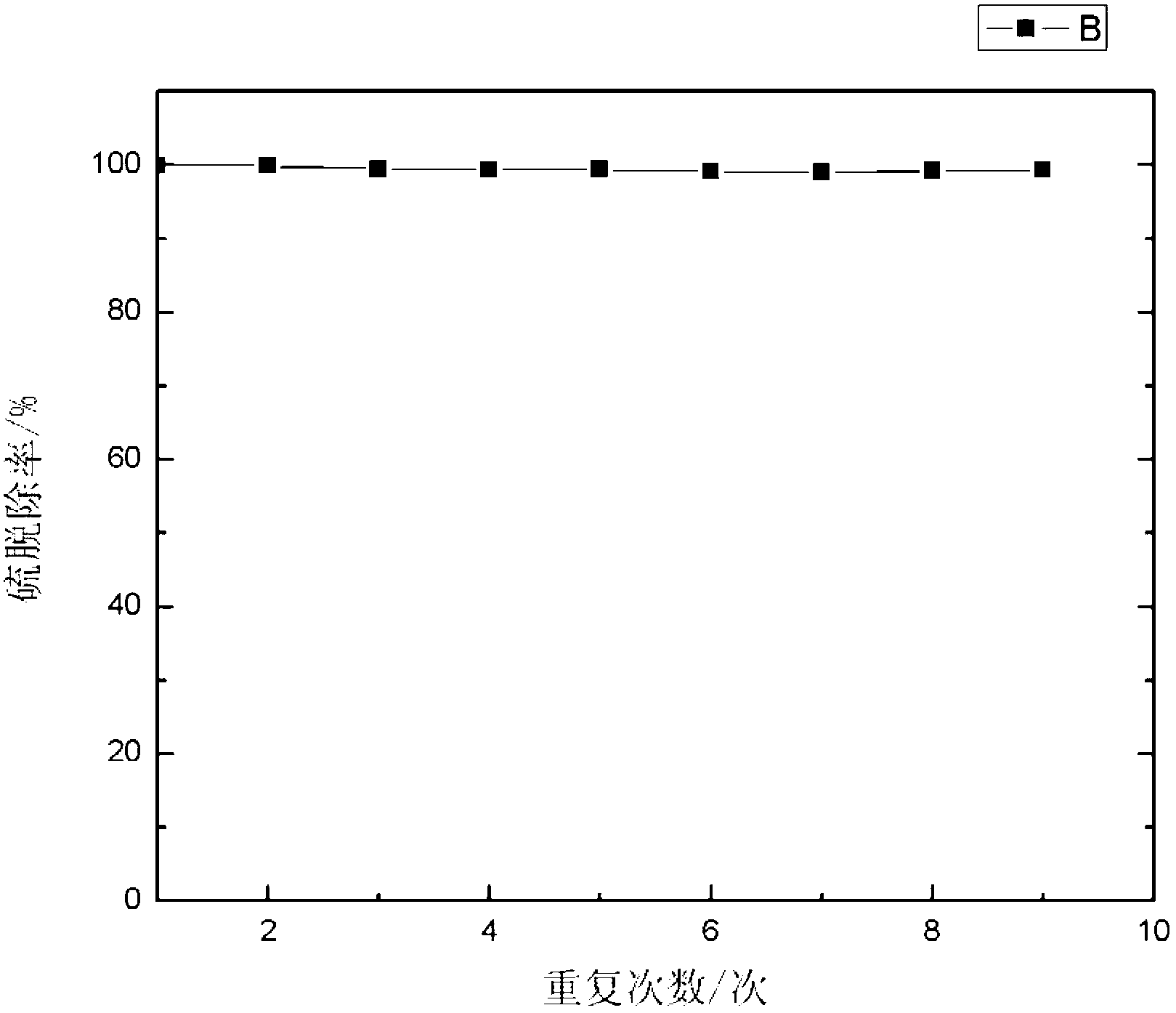

Examples

Embodiment 1

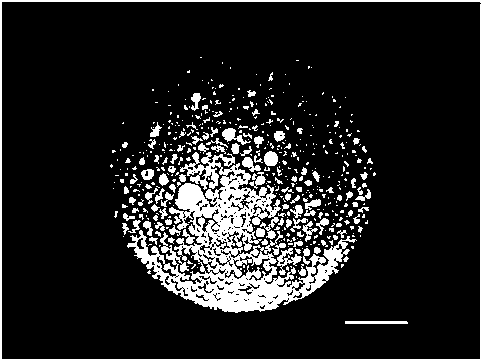

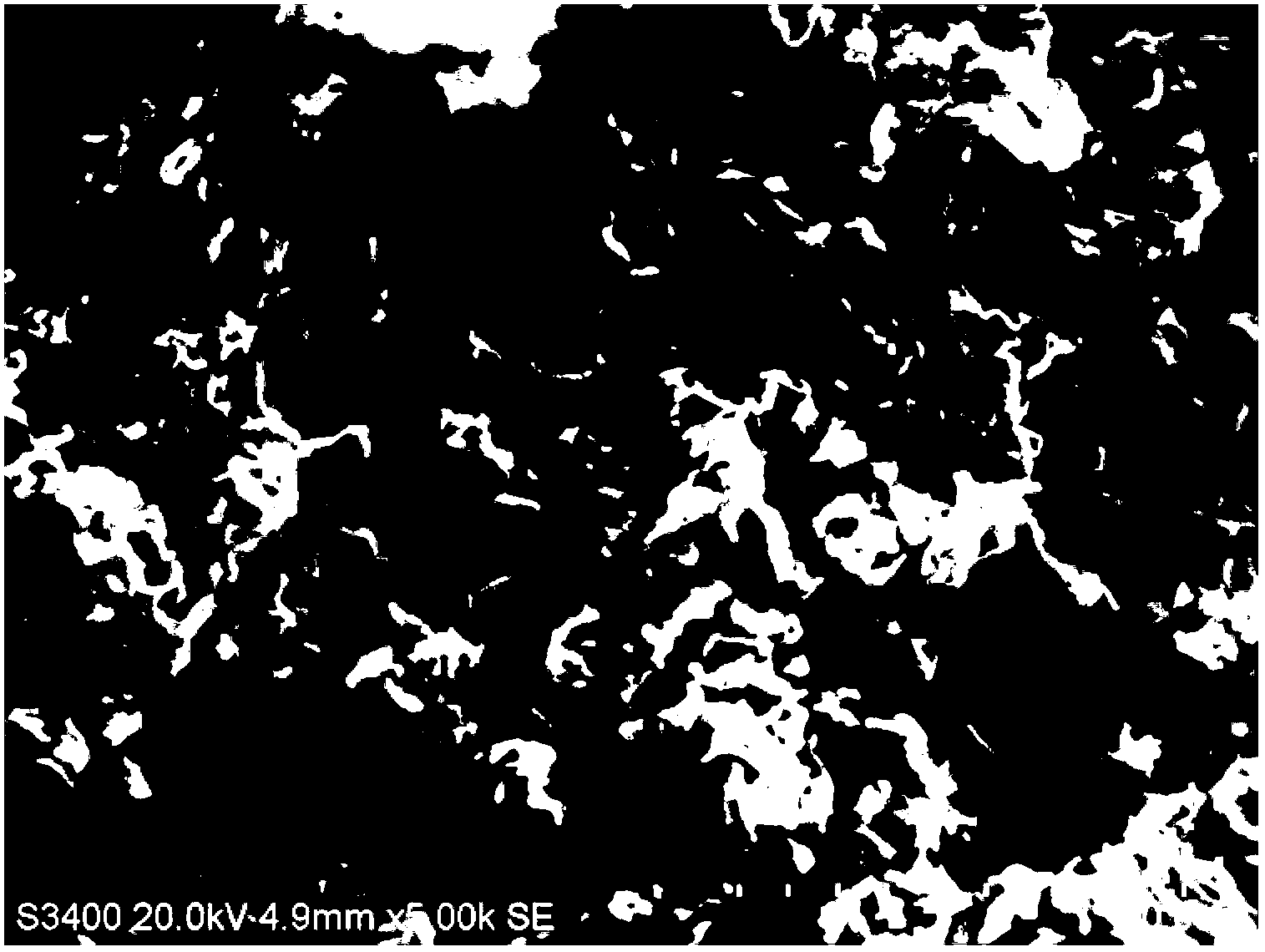

[0030] (1) In parts by weight, one part of graphene oxide was dissolved in 100 parts of water, ultrasonically dispersed for 3 hours, and then centrifuged in a centrifuge at 2000 rpm for 10 minutes to remove trace incompatible substances to obtain a 1% graphene oxide aqueous solution with a mass fraction.

[0031] (2) In parts by weight, dissolve 4 parts of polyether P123 in 100 parts of water, then add 10 parts of the graphene oxide aqueous solution prepared in step (1) and stir at 30°C for 1 hour, then add concentrated hydrochloric acid to make the hydrochloric acid of the mixed solution When the concentration reaches 2M, add 8.4 parts of tetraethyl orthosilicate (TEOS) to react at 40°C for 20h, and then age at 120°C for 24h. After suction filtration, the filter residue is dried at 60°C for 10h, and the dried solid is protected under nitrogen. Burn at 500°C for 10 hours to obtain the graphene-modified molecular sieve amphiphilic catalyst support S1-G10 (the value after G is th...

Embodiment 2

[0034] (1) In parts by weight, one part of graphene oxide was dissolved in 100 parts of water, ultrasonically dispersed for 3 hours, and then centrifuged in a centrifuge at 2000 rpm for 10 minutes to remove trace incompatible substances to obtain a 1% graphene oxide aqueous solution with a mass fraction.

[0035] (2) In parts by weight, dissolve 4 parts of polyether P123 in 100 parts of water, then add 10 parts of the graphene oxide aqueous solution prepared in step (1) and stir at 30°C for 1 hour, then add concentrated hydrochloric acid to make the hydrochloric acid of the mixed solution When the concentration reaches 2M, add 8.4 parts of tetraethyl orthosilicate (TEOS) to react at 40°C for 20h, and then age at 120°C for 24h. After suction filtration, the filter residue is dried at 60°C for 10h, and the dried solid is protected under nitrogen. Burn at 500°C for 10 hours to obtain the graphene-modified molecular sieve amphiphilic catalyst support S1-G10 (the value after G is th...

Embodiment 3

[0038] (1) In parts by weight, one part of graphene oxide was dissolved in 100 parts of water, ultrasonically dispersed for 2.5 hours, and then centrifuged in a centrifuge at 2500 rpm for 8 minutes to remove trace incompatible substances to obtain a 1% graphene oxide aqueous solution with a mass fraction.

[0039] (2) In parts by weight, dissolve 3 parts of polyether P123 in 80 parts of water, then add 15 parts of the graphene oxide aqueous solution prepared in step (1) and stir at 30°C for 1 hour, then add concentrated hydrochloric acid, which is the hydrochloric acid of the mixed solution When the concentration reaches 1M, add 8.4 parts of tetraethyl orthosilicate (TEOS), react at 40°C for 30h, and then age at 80°C for 48h. After suction filtration, the filter residue is dried at 100°C for 5h, and the dried solid is protected by argon. Burn at 500°C for 8 hours to obtain the graphene-modified molecular sieve amphiphilic catalyst support S2-G15.

[0040] The difference betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com