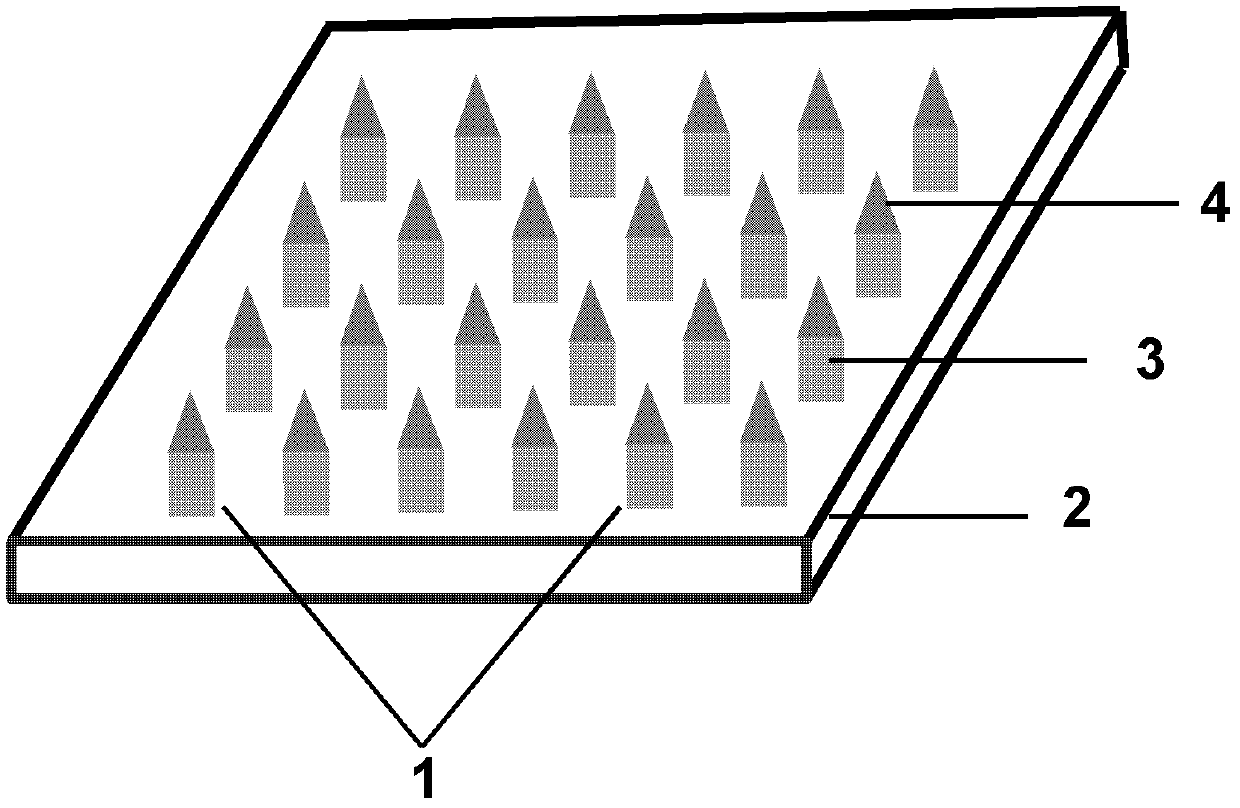

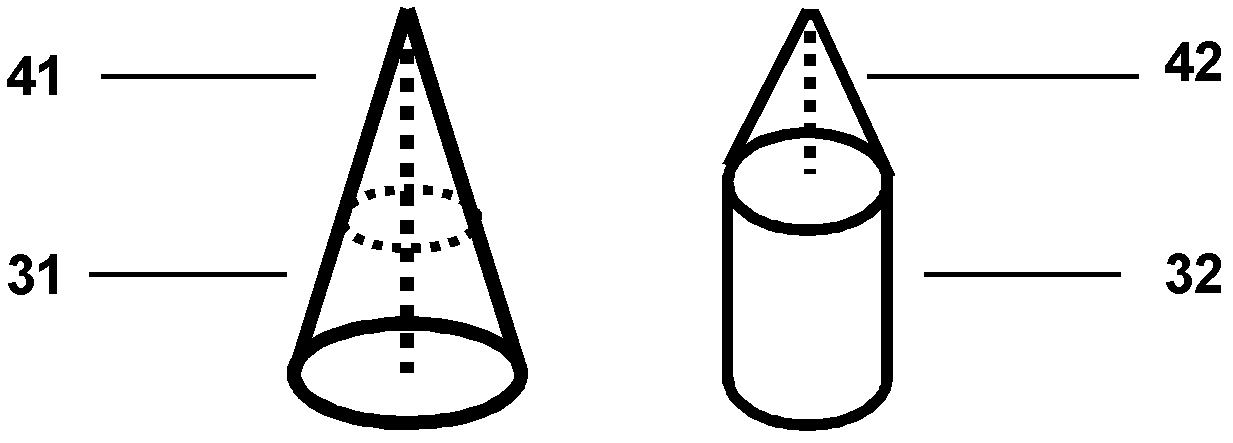

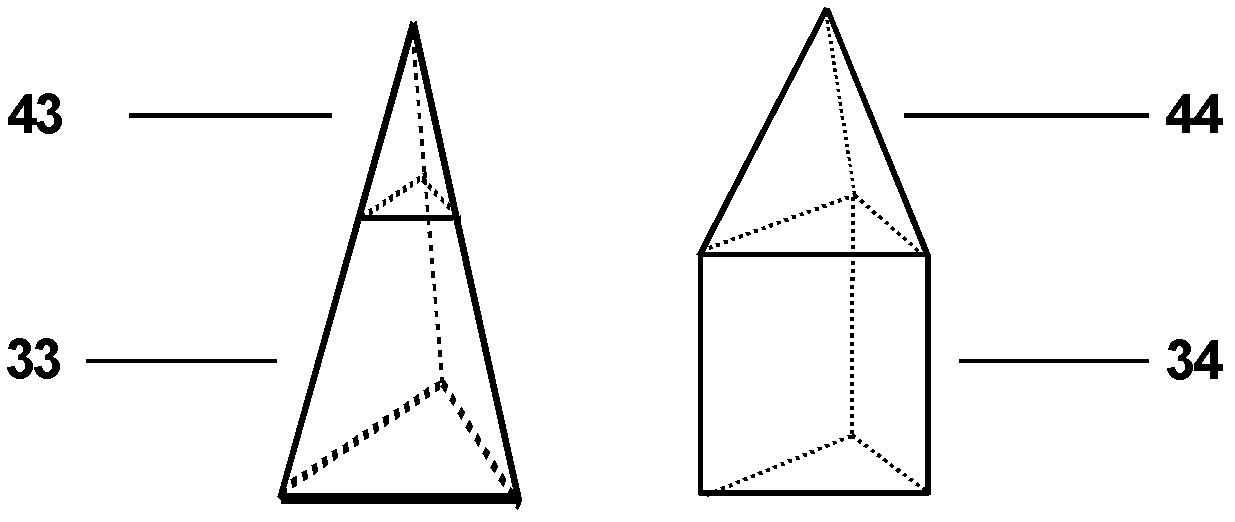

Polymer micro-needle array chip, and preparation method and application thereof

A microneedle array and polymer technology, applied in the field of biomedical materials and micro-processing, can solve the problems of loss of activity and insufficient mechanical strength to pierce the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0191] The invention provides a synthetic method for preparing the above-mentioned polyacrylamide polymer, which mainly includes the following steps:

[0192] S-1, in the reactor equipped with stirring device, add organic solvent, water and acrylamide monomer according to the set value;

[0193] The organic solvent of the present invention is mainly based on alcohols, supplemented by ketones. Alcohols are selected from at least one or a mixture of two or more of components such as methanol, ethanol, n-propanol, isopropanol, n-butanol; preferably, the volume percentage of the alcohol solvent in the reaction system is ≥ 60%; The ketones are selected from one of acetone, butanone, methyl isobutyl ketone and cyclohexanone, or a mixture of two or more of them. Preferably, the volume percentage of the ketone solvent in the reaction system is ≤25%; the present invention can control the molecular weight of the polymer by changing the volume percentage of the organic solvent in the re...

Embodiment 1

[0312] In a 250ml three-neck round-bottomed flask equipped with a mixed-flow condenser, a thermometer, and a nitrogen-equaling device, add water, ethanol, acetone, and isopropanol in sequence in a volume ratio of 2:5:10:83, and a total of 100ml is added through a magnetic stirrer. Mix it evenly; continue to add 10.66g of acrylamide monomer to the system, continue to stir to dissolve it; pass nitrogen gas, heat the reaction system through a water bath, and set the target temperature to 60°C; dissolve 107mg of azobisisobutyronitrile in In 10ml of isopropanol, mix evenly to make it fully dissolve. After the temperature of the reaction system reaches the target temperature of 60°C, add 1ml of isopropanol dissolved in azobisisobutyronitrile to the system, and keep it warm for 15 hours. Keep stirring during the reaction, and ensure the uninterrupted feeding of high-purity nitrogen;

[0313] After the reaction, the system was cooled, and the solid-liquid of the reaction system was se...

Embodiment 2

[0316] Same as Example 1, the proportioning of water, ethanol, acetone and isopropanol in changing solvents is 5:5:10:80. The content of residual acrylamide monomer in the polymer was detected by the Daofeng liquid chromatograph (LC-20A / SPD-20AV), and the measured value was ≤0.5ppm. Measure its molecular weight according to the GB 17514-2008 method in conjunction with the static light scattering method (Wyatt DAWN HELEOS-II), and the molecular weight of the obtained polymer is about 1.35×10 5 . The Vickers hardness of the corresponding block material is about 300HV measured according to the GB / T4340.2 standard. According to the D-256 standard of American ATSM, the impact strength is about 25J / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com