Preparation method of PPS (polyphenylene sulfide)-based N-methylimidazole strong base type ion exchange fiber

A technology of methyl imidazole and exchange fiber, which is applied in the field of preparation of strong alkali ion exchange fiber, can solve the problems of complicated synthesis steps, high price of polytetrafluoroethylene, and achieves good chemical stability, good adsorption and regeneration performance, adsorption and regeneration. large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of PPS-based N-methylimidazole strong base ion exchange fiber of the present invention, its detailed steps are as follows:

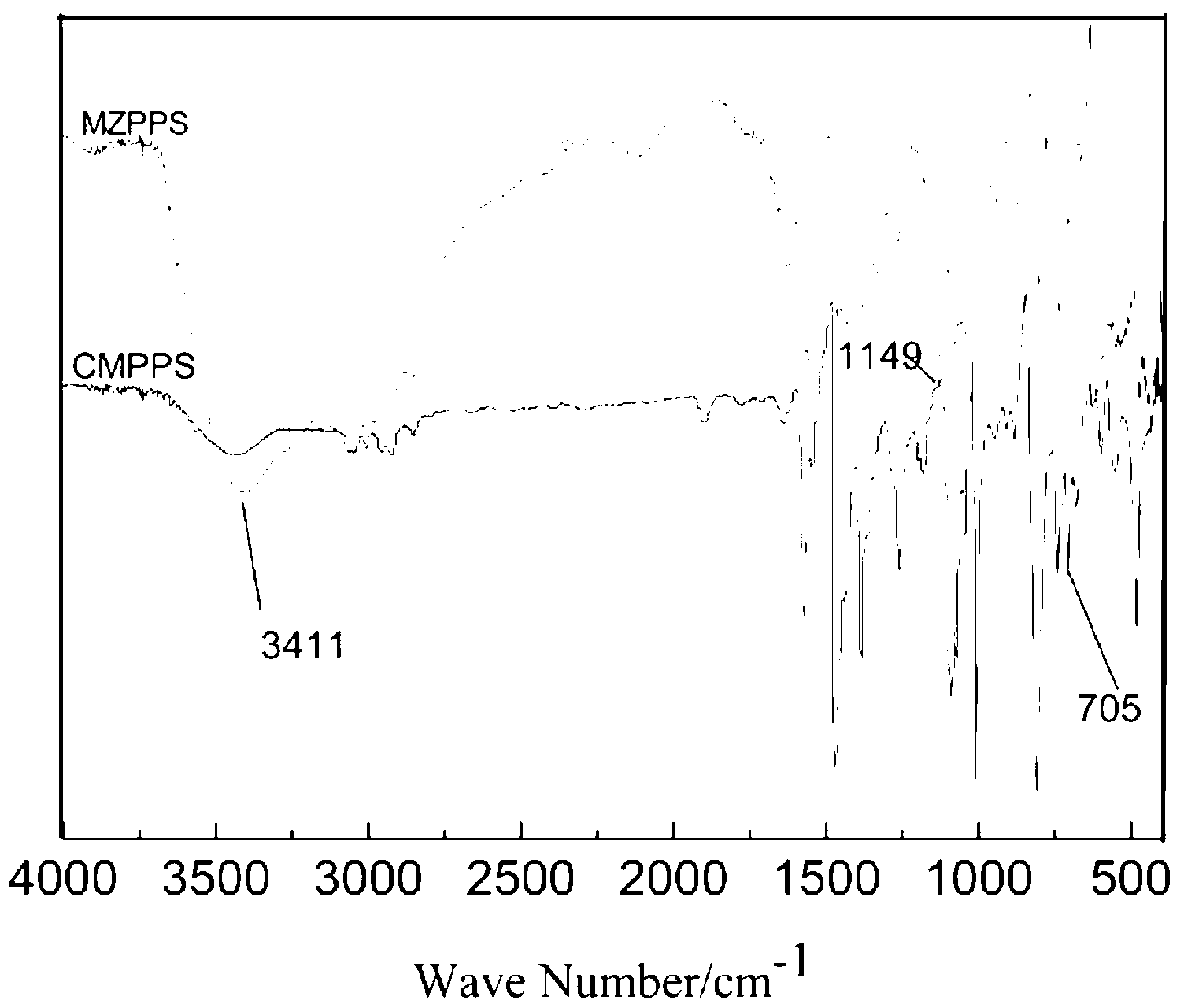

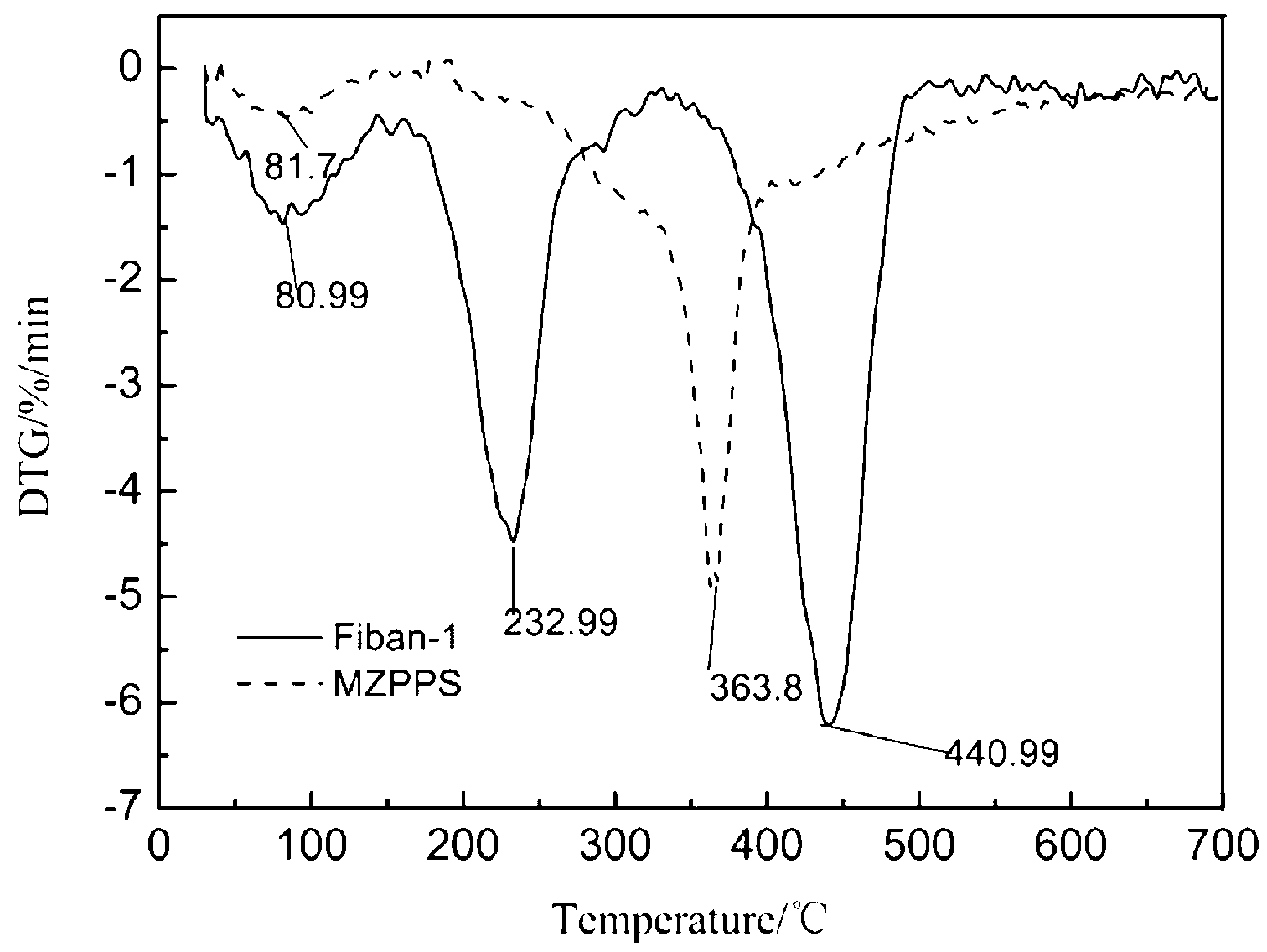

[0034] a. Preparation of chloromethylated polyphenylene sulfide fiber: Weigh 6.8896g of polyphenylene sulfide fiber and place it in a hydrothermal kettle, add solvent dichloroethane 30mL, chloromethyl ether 50mL and catalyst anhydrous tetrachloride Tin 2mL screw tight, swell for 16h; after swelling, place the hydrothermal kettle in a 100°C oil bath to heat for 2h, cool to room temperature after heating, and filter out the product after cooling; Soak in HCl for 10 hours, extract with ethanol for 6 hours, wash with water until neutral, then vacuum dry to constant weight (vacuum degree 0.08Mpa, drying temperature 60°C, drying time 24 hours), and dry to obtain chloromethylated polyphenylene sulfide fibers; (Compared to the 34.40% weight gain of the original polyphenylene sulfide fiber, the elemental analysis results of the chlor...

Embodiment 2

[0036] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0037] a. Preparation of chloromethylated polyphenylene sulfide fiber: Weigh 6.9807g of polyphenylene sulfide fiber into a hydrothermal kettle, add solvent dichloroethane 30mL, chloromethyl ether 50mL and catalyst anhydrous tin tetrachloride Tighten 2mL and swell for 18h; after swelling, place the hydrothermal kettle in an oil bath at 100°C for heating reaction for 2h, cool to room temperature after heating, and filter out the obtained product after cooling; soak the obtained product in 5mol / L HCl for 12h in turn , extracted with ethanol for 6 hours, washed with water until neutral, vacuum-dried to constant weight (vacuum degree 0.08Mpa, drying temperature 60°C, drying time 24h), after drying, chloromethylated polyphenylene sulfide fibers were obtained; (the obtained chloromethyl Compared with the original polyphenylene sulfide fiber, the weight gain of the modified polyphenylene sulfide fiber is 35....

Embodiment 3

[0039] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0040] In step b: Weigh 4.0764 g of the chloromethylated polyphenylene sulfide fiber prepared in step a, put it in a 250 mL three-neck flask, add 100 mL of dichloroethane to swell for 20 hours, add 100 mL of ethanol, 7.01 mL of N-methyl 0.42 g of imidazole and tetrabutylammonium bromide, heat the reaction solution to 55 ° C for 10 h, after the reaction, filter out the fiber, wash the obtained fiber with distilled water until it is neutral, and place it in a Soxhlet extractor after washing Extract with ethanol for 8 hours, soak in 1 mol / L hydrochloric acid solution for 12 hours after extraction, wash the product with distilled water until neutral, and finally vacuum dry to constant weight (vacuum degree 0.08Mpa, drying temperature 80°C, drying time 24 hours ), after drying, PPS-based N-methylimidazole type strong base ion exchange fibers were obtained (the quality of the obtained PPS-based N-methylimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com