Silver-carbon-codoped bicrystal mesoporous titanium dioxide visible light photocatalyst and preparation method thereof

A technology of mesoporous titanium dioxide and photocatalyst, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of weak photocatalytic activity of visible light, and achieve improvement Effect of photocatalytic activity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of twin-crystal mesoporous titania:

[0031] Dissolve 0.8g of surfactant P123 in 30ml of ethanol, stir for 30 minutes, then slowly add 1.0g of titanium tetrachloride and 0.8g of titanium isopropoxide, continue stirring for 60 minutes, then pour the sol from the beaker into an evaporating dish, Place the evaporating dish containing the sol in a constant temperature and humidity box with a relative humidity of 80% and a temperature of 45° C. for 24 hours, and finally obtain a white mesoporous titanium dioxide powder;

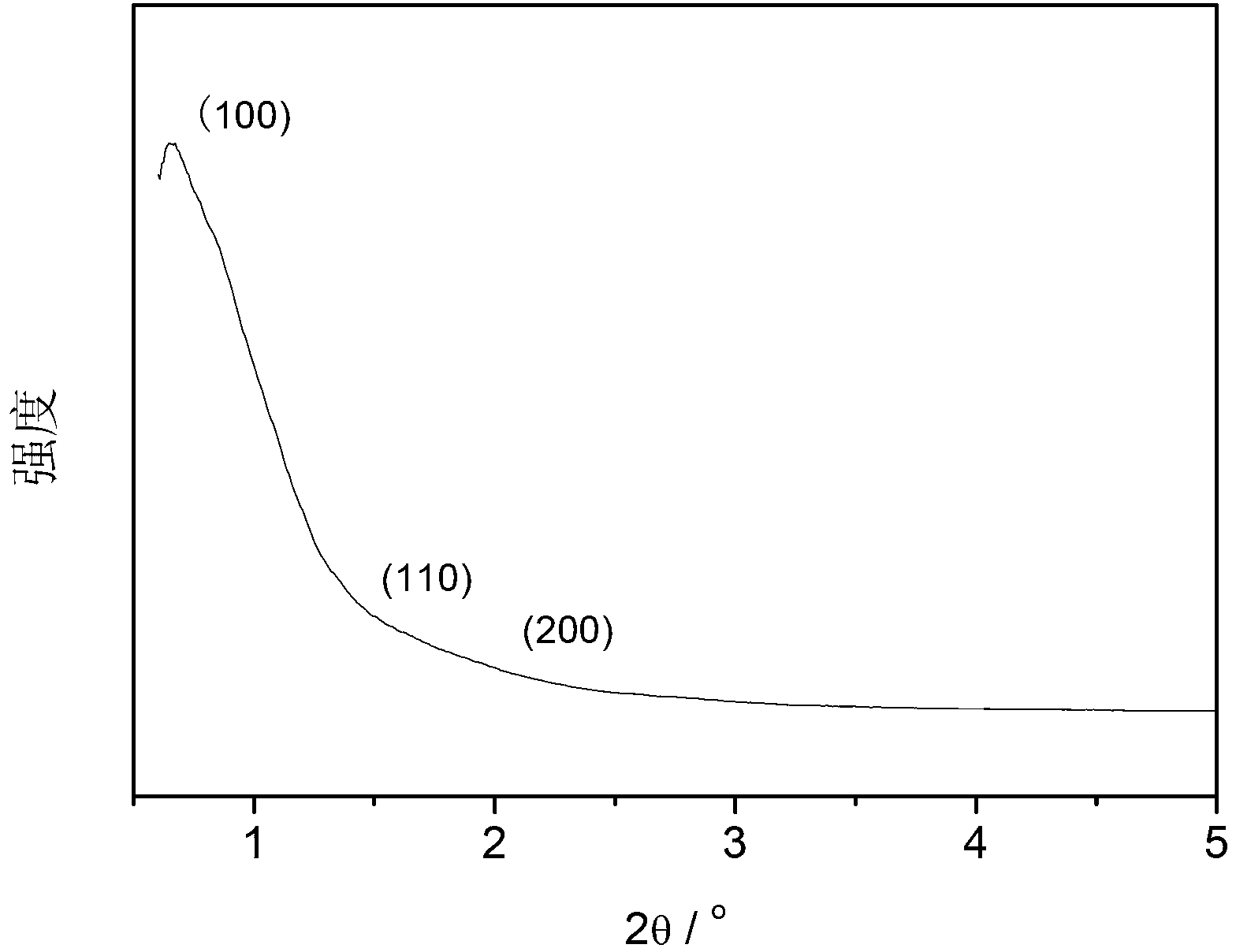

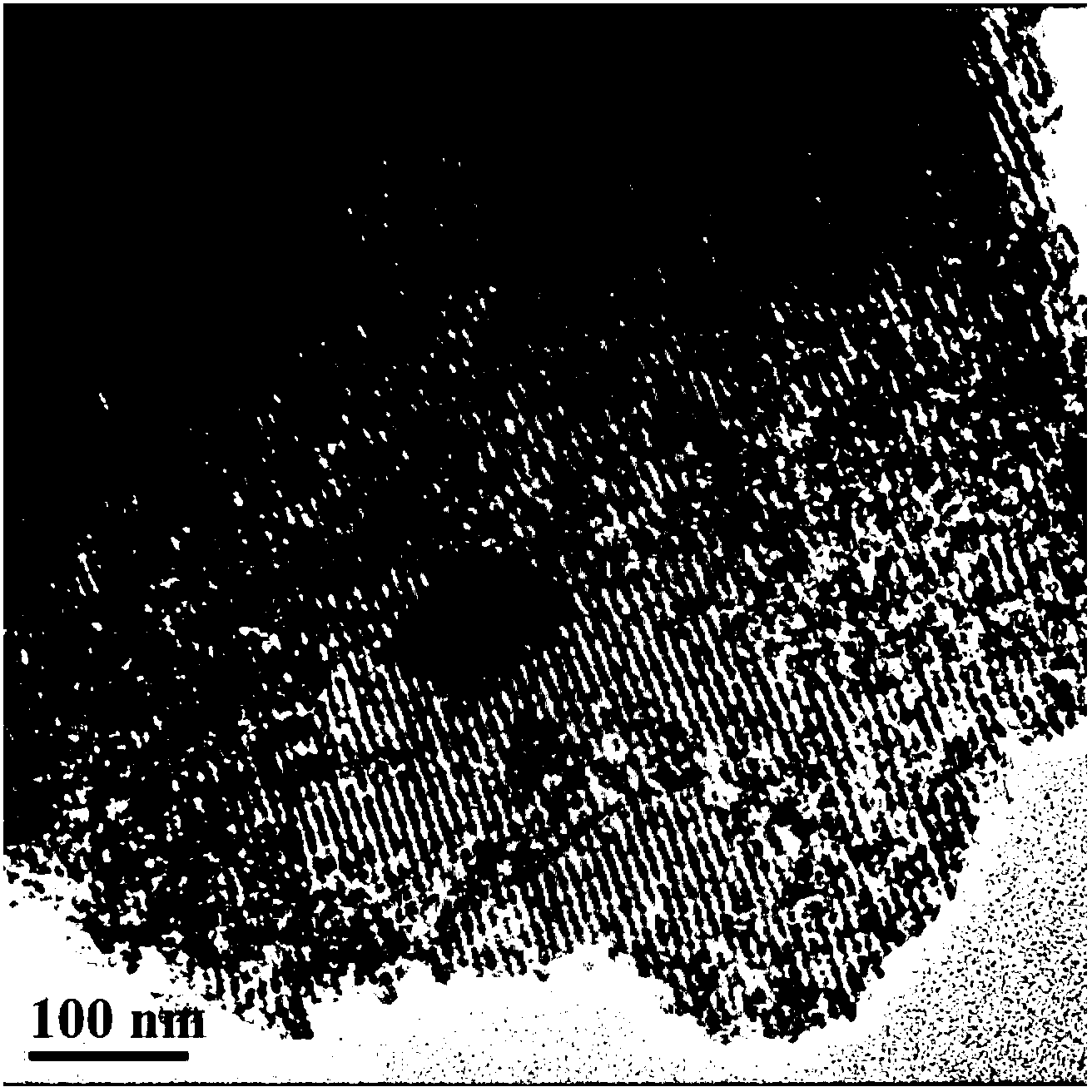

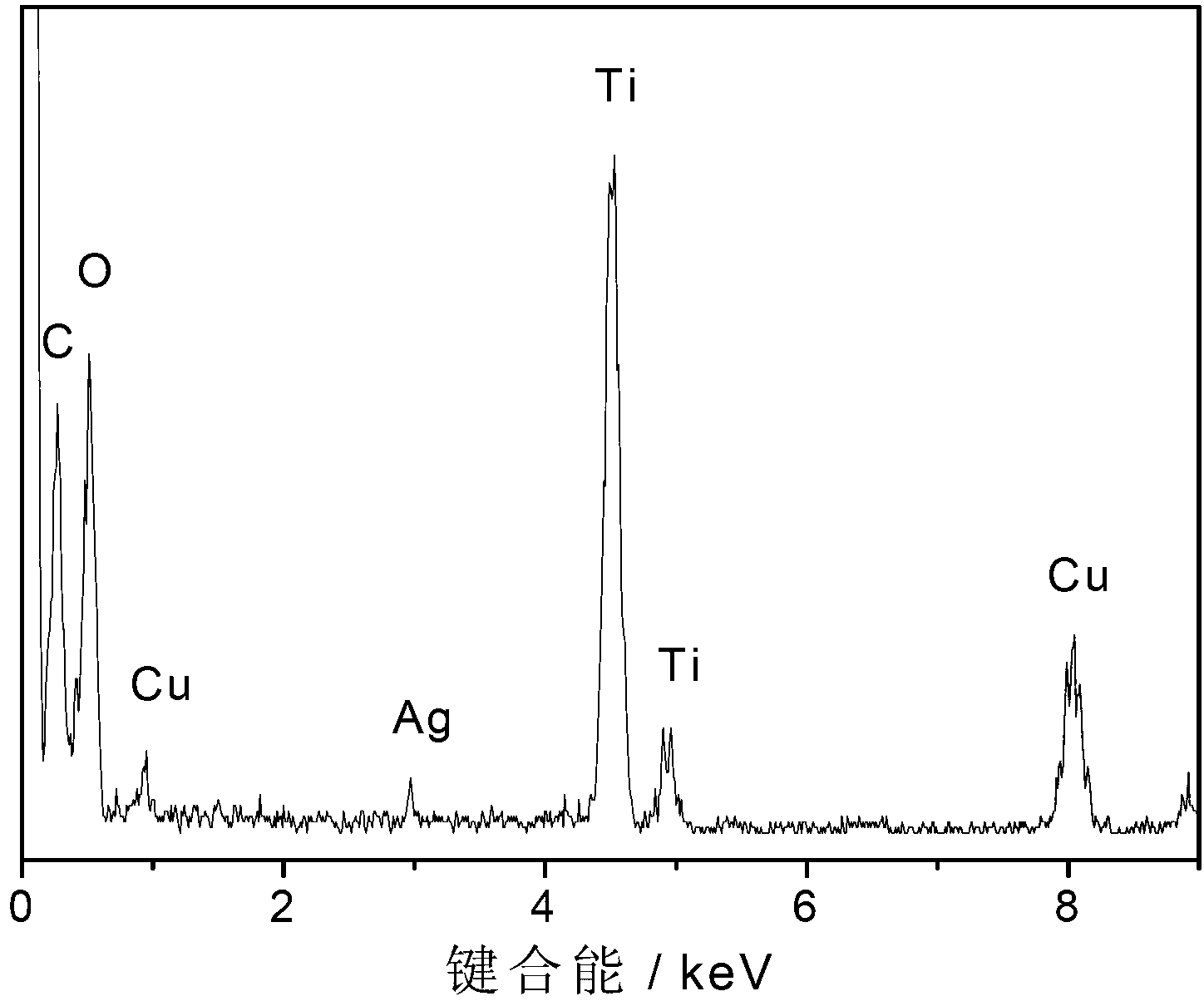

[0032] The above mesoporous titanium dioxide powder was calcined for 4 hours in a nitrogen atmosphere at a temperature of 400°C, then switched to an air atmosphere at a temperature of 300°C, and continued to be calcined for 2 hours to obtain a twin-crystal mesoporous titanium dioxide with an anatase phase and a rutile phase skeleton , its small-angle XRD diffraction pattern is as follows figure 1 As shown, its TEM picture is shown in figure 2...

Embodiment 2

[0045] Preparation of twin crystal mesoporous titania

[0046] With embodiment 1.

[0047] Preparation of silver-carbon co-doped twin-crystal mesoporous titania

[0048] Experimental medicine used and operating procedure are the same as embodiment 1, and the consumption of changing silver nitrate is: 0.25g. The silver content of the sample was 2.6 wt.%.

[0049] Visible-light photocatalytic activity of silver-carbon co-doped bicrystalline mesoporous titania

[0050] The experimental conditions were the same as in Example 1, and the degradation rate of methylene blue was 68% after 180 minutes of visible light irradiation.

Embodiment 3

[0052] Preparation of twin crystal mesoporous titania

[0053] With embodiment 1.

[0054] Preparation of silver-carbon co-doped twin-crystal mesoporous titania

[0055] Used experimental medicine and operation steps are the same as embodiment 1, the consumption of changing silver nitrate is: 0.2g. The silver content of the sample was 2.1 wt.%.

[0056] Visible-light photocatalytic activity of silver-carbon co-doped bicrystalline mesoporous titania

[0057] The experimental conditions are the same as in Example 1, and the degradation rate of methylene blue after 180 minutes of visible light irradiation is 63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com