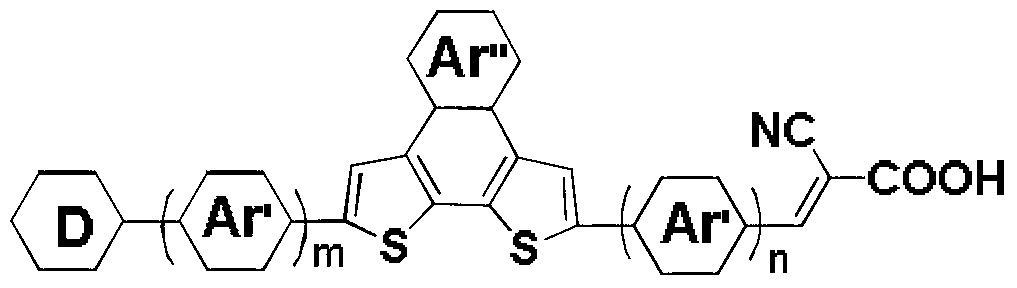

Dye based on dibenzothiophene derivative as well as synthesis method and application thereof

A technology of benzene derivatives and dithiophene, applied in the field of dyes and their synthesis based on dithienoacene derivatives, can solve problems such as large-scale industrialization restrictions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

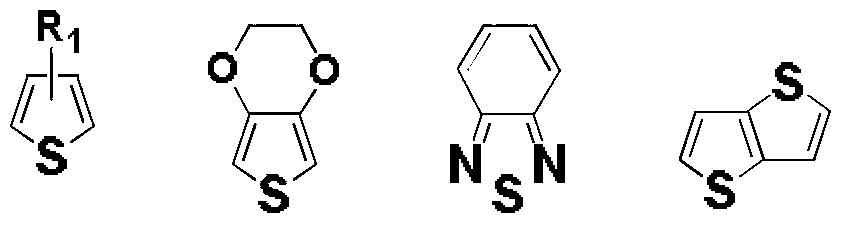

Method used

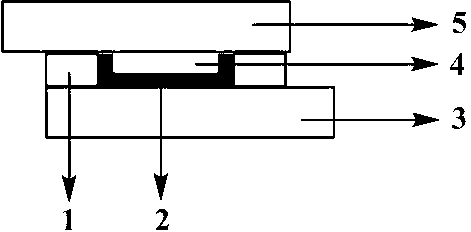

Image

Examples

Embodiment 1

[0055] Embodiment 1: the preparation of dye intermediate 1c

[0056] Under nitrogen protection, 1.97g (3.01mmol) 1a (Wang, B.; Tsang, S.-W.; Zhang, W.; Tao, Y.; Wong, M.S.Chem.Commun., 2011,47,9471 .), 1.02g (7.00mmol) 1b was dissolved in 40mL toluene, and 70mg (0.06mmol) Pd(PPh 3 ) 4 , 2.76g (20.00mmol) K 2 CO 3 , 10mL H 2 O, heated to 85°C, reacted for 15 hours, when the reaction was complete, poured the reaction system into water, extracted with dichloromethane, washed the organic phase with water several times, dried, removed the solvent, and purified by column separation to obtain 1.67g of compound 1c , yield 84%.

Embodiment 2

[0057] Embodiment 2: the preparation of dye intermediate 1d

[0058]Under nitrogen protection, dissolve 1.50g (2.27mmol) of 1c in 30mL of dichloromethane, add 0.24mL (2.58mmol) of phosphorus oxychloride, 0.28mL (3.62mmol) of N,N-dimethylformamide (DMF ), heated to 70° C. and refluxed for 8 hours. After the reaction was completed, saturated sodium acetate was added and stirred for half an hour, and the pH value of the solution was adjusted to 7 with sodium hydroxide solution. It was extracted with dichloromethane, the organic phase was washed several times with water, dried, the solvent was removed, and 1.41 g of compound 1d was obtained by column separation and purification with a yield of 90%.

Embodiment 3

[0059] Embodiment 3: the preparation of dye intermediate 1e

[0060] Under nitrogen protection, dissolve 1.29g (1.87mmol) 1d in 30mL chloroform and 10mL glacial acetic acid, add 0.40g (2.25mmol) N-bromosuccinimide (NBS), stir at room temperature for 5 hours, after the reaction , adding water to terminate the reaction, extracting with dichloromethane, washing the organic phase with sodium hydroxide solution and water several times, drying, removing the solvent, and column separation and purification to obtain 1.16 g of compound 1e, with a yield of 81%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com