Hyperbranched modified hydroxy acrylic resin aqueous dispersion, and preparation method and application thereof

A hydroxyacrylic acid and dispersion technology, applied in the direction of graft polymer adhesives, adhesive types, adhesives, etc., can solve the problems of high solid content and low viscosity, and achieve excellent UV resistance and viscosity reduction. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

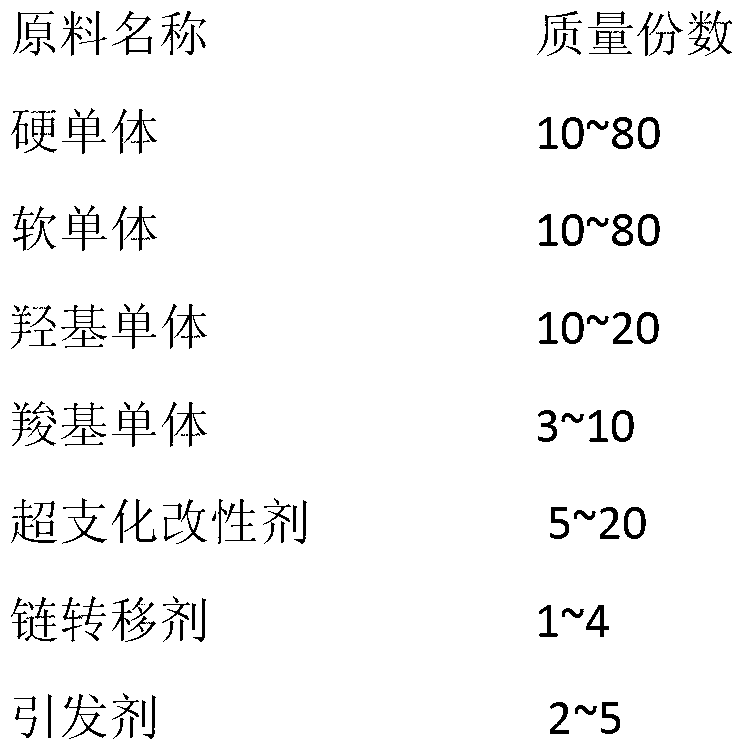

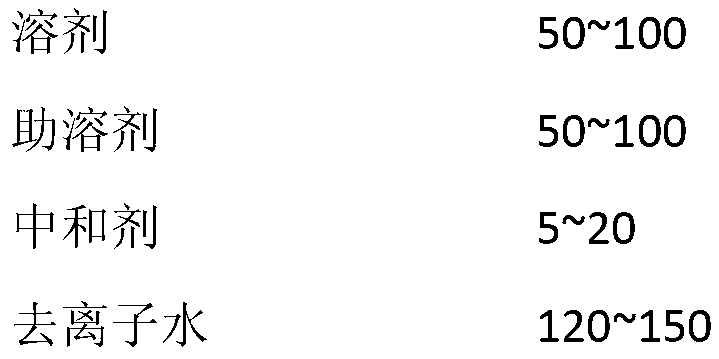

Method used

Image

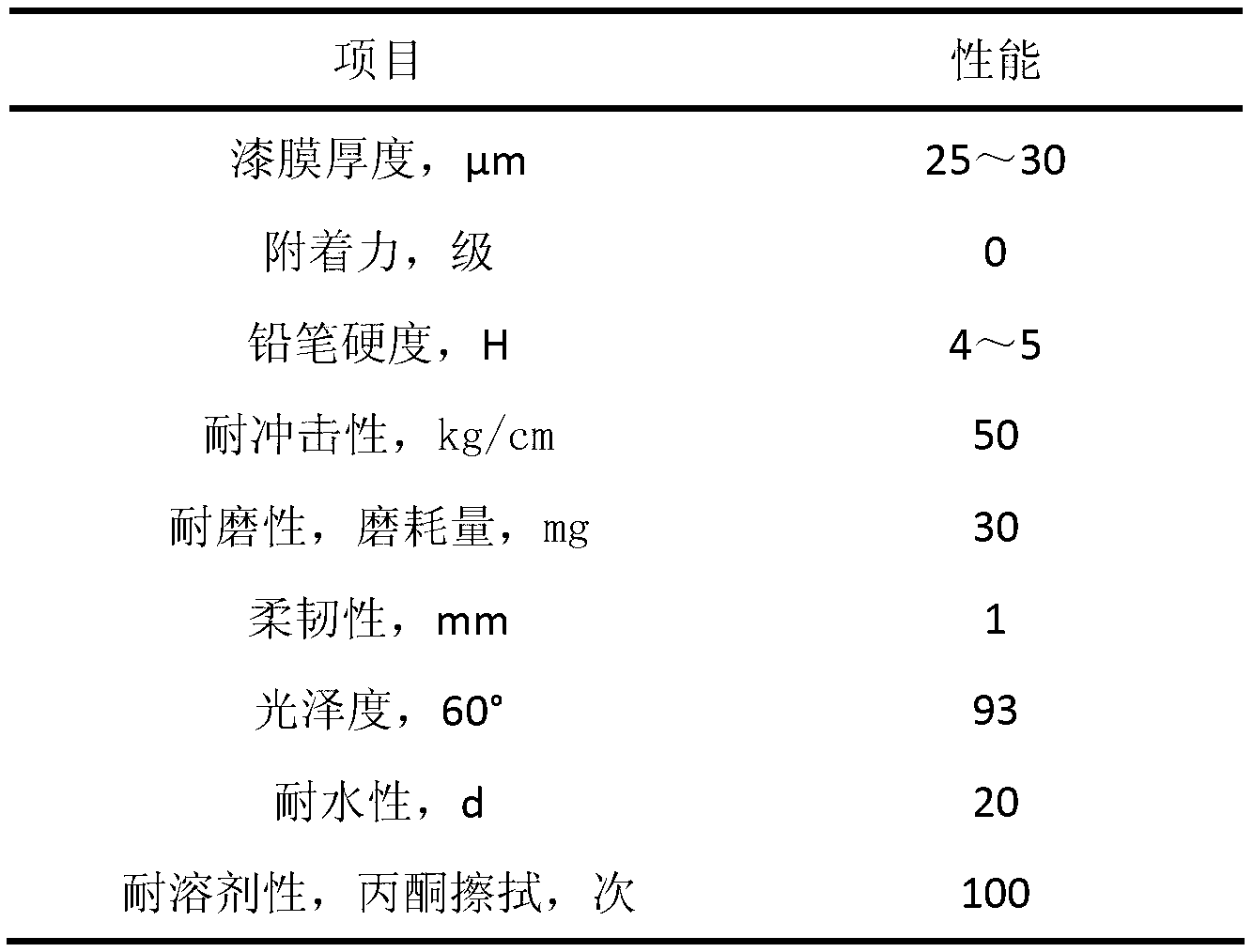

Examples

Embodiment 1

[0034] Embodiment 1: the preparation of hyperbranched polyester acrylate modified hydroxyl acrylic resin aqueous dispersion

[0035]Add 75g of propylene glycol methyl ether acetate and 1g of initiator di-tert-butyl peroxide into a 500ml four-necked flask equipped with a stirrer, condenser, thermometer, and oil bath, stir and heat up to reflux under nitrogen protection Temperature 180°C; 10g butyl acrylate, 22g hydroxyethyl acrylate, 45g methyl methacrylate, 3g acrylic acid, 10g styrene, 10g terminal alkenyl hyperbranched polyester acrylate Boltorn B-H20 (Sweden Perstorp company), Add 3.5g of di-tert-butyl peroxide and 5g of dodecyl mercaptan into the beaker and stir magnetically for 15 minutes to mix evenly to obtain the mixed raw materials. After the temperature in the flask is raised to 180°C, pre-inject 10% of the above mixed raw materials into the flask at one time. , to make reaction "seeds"; after half an hour, use a constant flow pump to slowly drop the remaining mixed ...

Embodiment 2

[0037] Embodiment 2: Preparation of hyperbranched polyurethane acrylate modified hydroxyl acrylic resin aqueous dispersion

[0038] Add 75g of propylene glycol butyl ether and 1g of initiator di-tert-butyl peroxide into a 500ml four-neck flask equipped with a stirrer, condenser, thermometer, and oil bath as a base material, stir, and heat up to a reflux temperature of 120°C under nitrogen protection. ℃; 10g butyl acrylate, 22g hydroxyethyl acrylate, 45g methyl methacrylate, 3g acrylic acid, 10g styrene, 10g terminal alkenyl hyperbranched polyurethane acrylate (HBPUA) (Sweden Perstorp company), 3.5g di-tert Butyl peroxide and 5g of dodecyl mercaptan were added to the beaker and stirred magnetically for 15 minutes to mix evenly to prepare mixed raw materials. After the temperature in the flask was raised to 120°C, 10% of the above mixed raw materials were pre-injected into the flask at one time and reacted" After half an hour, use a constant flow pump to slowly drop the remainin...

Embodiment 3

[0040] Embodiment 3: Preparation of hyperbranched polyether acrylate modified hydroxyl acrylic resin aqueous dispersion

[0041] Add 75g of propylene glycol butyl ether and 1g of initiator di-tert-butyl peroxide into a 500ml four-neck flask equipped with a stirrer, condenser, thermometer, and oil bath as a base material, stir, and heat up to a reflux temperature of 150 ℃; 10g butyl acrylate, 22g hydroxyethyl acrylate, 45g methyl methacrylate, 3g acrylic acid, 10g styrene, 10g terminal alkenyl hyperbranched polyether acrylate (Perstorp, Sweden), 3.5g di-tert-butyl Add peroxide and 5g of dodecyl mercaptan into the beaker and stir magnetically for 15 minutes to mix evenly to prepare mixed raw materials. After the temperature in the flask is raised to 150°C, 10% of the above mixed raw materials are pre-injected into the flask at one time to make reaction "seeds" After half an hour, use a constant flow pump to slowly drop the remaining mixed raw materials into the four-necked flask...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com