Regenerated silk fibroin solution and preparation method thereof

A technology for regenerated silk fibroin and solution, applied in the field of regenerated silk fibroin solution and its preparation, can solve the problems of high material brittleness, low strength, and limit the wide application of industrial production of silk fibroin, and achieve excellent mechanical properties, fast dissolution, Simple and efficient processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Natural mulberry silk was degummed by boiling with 0.1wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0026] (2) Prepare natural degummed silk solution: dilute 98% formic acid to 80% with water, then add lithium bromide to make 80% formic acid solution containing 2% lithium bromide, which is silk solution;

[0027] (3) The degummed silk from step (1) was dissolved in the dissolving solution of step (2) at a concentration of 5%, the dissolving temperature was 60° C., and the regenerated silk fibroin protein solution was obtained by stirring at a low speed for 2 hours.

Embodiment 2

[0029] (1) Natural mulberry silk was degummed by boiling 0.05wt% sodium bicarbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0030] (2) Prepare natural degummed silk solution: add 5% calcium chloride to 98% formic acid to obtain silk solution;

[0031] (3) Dissolving the degummed silk in step (1) in the solution of step (2) at a concentration of 20%, at a dissolution temperature of 30°C, stirring at a low speed for 4 hours to obtain a regenerated silk fibroin solution;

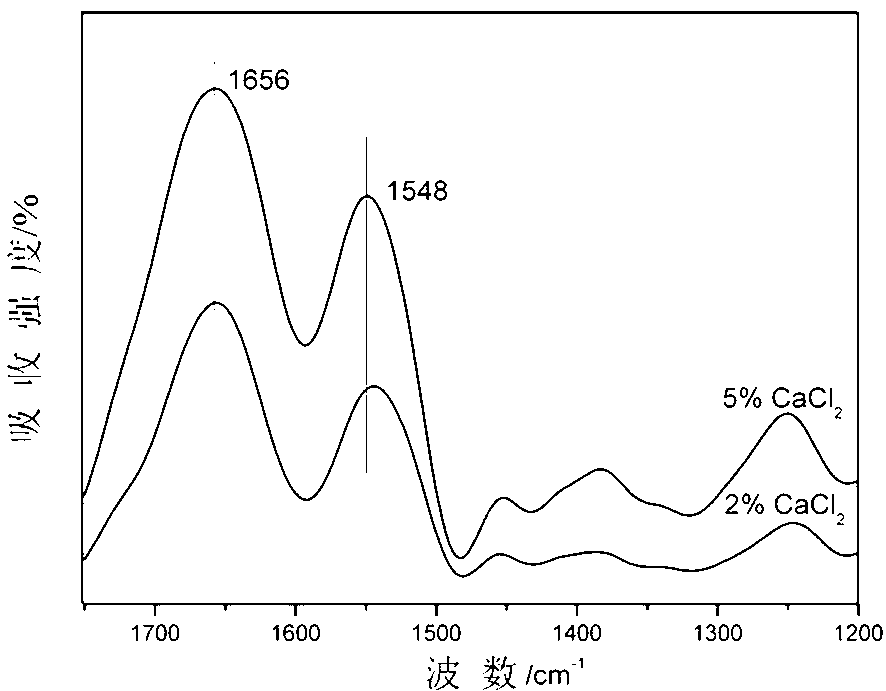

[0032] attached figure 1 For the infrared spectrogram of the regenerated silk fibroin solution prepared in embodiment one and embodiment two after drying on potassium bromide tablet, see figure 1 , in the regenerated silk fibroin solution prepared according to the technical scheme provided by the present invention, the silk fibroin structure is mainly amorphous.

Embodiment 3

[0034] (1) Natural mulberry silk was degummed by boiling 0.5wt% sodium carbonate solution for 30 minutes, and degummed mulberry silk was obtained after repeating 3 times;

[0035] (2) Prepare natural degummed silk solution: dilute 85% phosphoric acid to 30% with water, then add lithium bromide to make 30% phosphoric acid solution containing 5% lithium bromide, which is silk solution;

[0036] (3) The degummed silk from step (1) was dissolved in the dissolving solution of step (2) at a concentration of 15%, the dissolving temperature was 60°C, and the regenerated silk fibroin protein solution was obtained by stirring at a low speed for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com