Soap powder composition containing sodium fatty acid methyl ester sulfonate and preparation method thereof

A technology of sodium fatty acid methyl ester sulfonate and composition, which is applied in the field of daily chemicals, can solve problems such as MES stability concerns, and achieve the effect of improving the performance of soap powder, good decontamination performance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

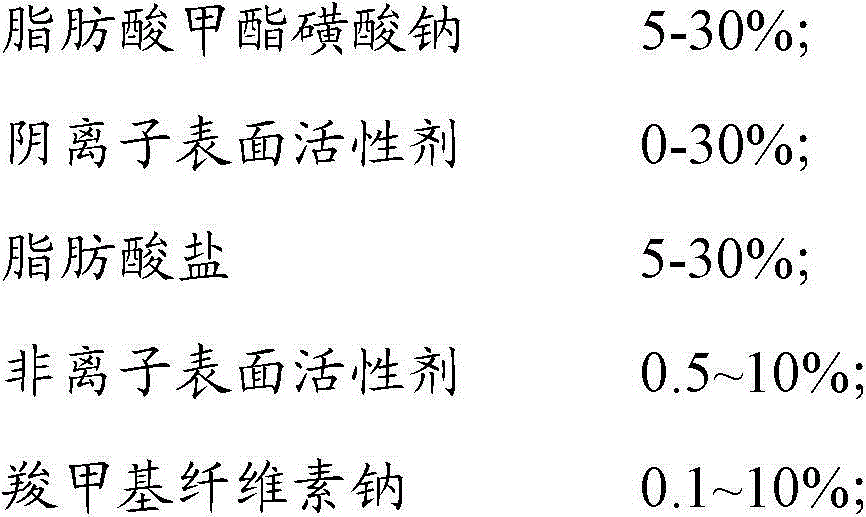

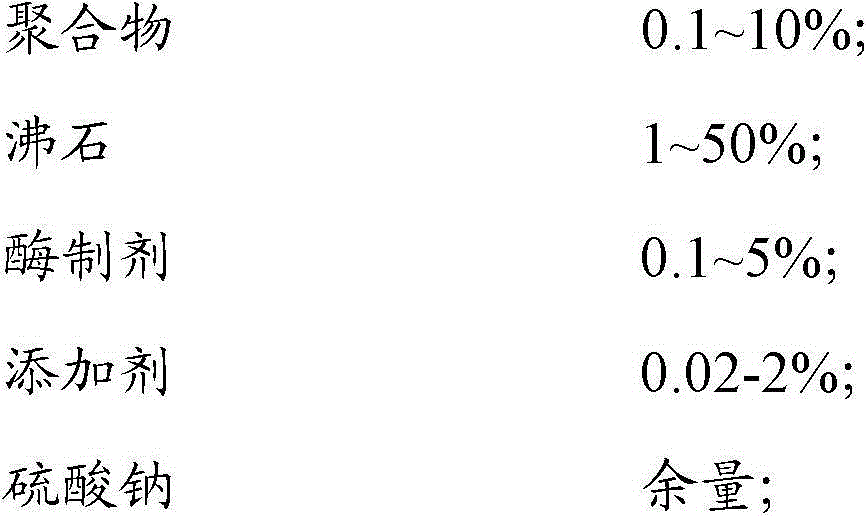

Method used

Image

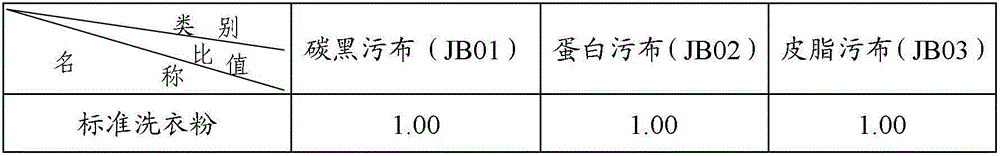

Examples

Embodiment 1

[0030] A soap powder containing fatty acid methyl ester sodium sulfonate (MES), comprising 5 parts of MES, 10 parts of coconut oil fatty acid sodium, 5 parts of alpha-olefin sulfonate, and 2 parts of fatty alcohol polyoxyethylene (9) ether of C12-C16 1 part, 1 part of maleic acid-acrylic acid copolymer, 1 part of sodium carboxymethylcellulose (CMC) with a degree of substitution of 0.7, 10 parts of 4A zeolite, 45 parts of sodium sulfate, 0.2 parts of stilbene biphenyl fluorescent whitening agent 20 parts of water, 0.1 part of protease and 0.3 part of essence.

[0031] Its preparation method is as follows:

[0032] (1) prepare materials according to the content of each component mentioned above;

[0033] (2) Add MES, sodium coconut oil fatty acid, sodium α-olefin sulfonate, C12-C16 fatty alcohol polyoxyethylene (9) ether, polymer (maleic acid-acrylic acid copolymer), CMC to the batching tank in sequence , 4A zeolite, sodium sulfate, brightener and water; start stirring to make...

Embodiment 2

[0036]A soap powder containing fatty acid methyl ester sodium sulfonate (MES), comprising 18 parts of MES, 10 parts of coconut oil fatty acid sodium, 10 parts of fatty alcohol polyoxyethylene ether sulfate, and C12-C16 fatty alcohol polyoxyethylene (7) 4 parts of ether, 2.5 parts of acrylic acid homopolymer, 5 parts of CMC with a substitution degree of 1.0, 20 parts of 4A zeolite, 20 parts of sodium sulfate, 0.15 parts of bistriazineaminostilbene fluorescent whitening agent, 10 parts of water, and 0.15 parts of protease , 0.1 part of lipase and 0.3 part of essence.

[0037] The preparation method of this soap powder is substantially the same as the preparation method in Example 1.

Embodiment 3

[0039] A soap powder containing sodium fatty acid methyl ester sulfonate (MES), including 30 parts of MES, 5 parts of linear alkylbenzene sulfonate sodium, 5 parts of coconut oil fatty acid sodium, 5 parts of C12-C14 alkyl glycoside, Malay 5 parts of acid-acrylic acid copolymer, 8 parts of CMC with a substitution degree of 1.2, 25 parts of 4A zeolite, 10 parts of sodium sulfate, 0.15 parts of bistriazineaminostilbene fluorescent whitening agent, 5 parts of water, 0.25 parts of protease and essence 0.3 parts.

[0040] The preparation method of this soap powder is substantially the same as the preparation method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com