A polycrystalline ingot furnace

A polycrystalline ingot and protective layer technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems affecting the service life of graphite hard felt, graphite hard felt corrosion, etc., to improve the temperature around the silicon ingot , avoid corrosion, reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A polycrystalline ingot casting furnace, comprising a heat sink 1, a quartz crucible 2, a heater 3, a heat insulation baffle 4, a heat dissipation window 5 and a heat insulation layer 6, the inner wall of the heat insulation layer 6 is covered with a reflective protective layer 7; The thickness of the protective layer (7) is 3-5mm.

[0032] The height of the reflective protective layer 7 is 200-500mm.

[0033] The lower part of the reflective protective layer 7 is flush with the upper surface of the cooling platform (1).

[0034] The surface of the reflective protective layer 7 is a transverse sawtooth surface 8, and the depth of the sawtooth is 0.5-2.5mm.

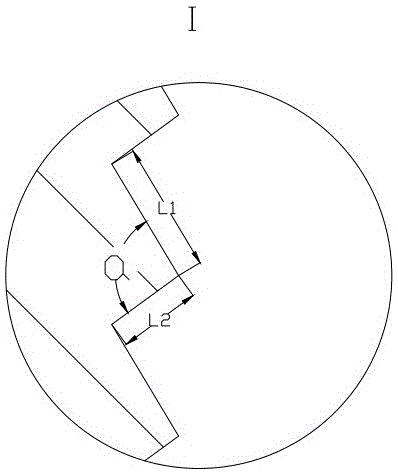

[0035] The sharp angle a of the serrated surface 8 is greater than 60°, and the length L of the two sides of the sharp angle a 1 greater than L 2 .

[0036] The material of the reflective protection layer 7 has a melting point higher than 1600° C. and does not react with silicon monoxide.

[0037] The reflectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com