Simultaneous desulphurization and denitration device for seawater smoke with membrane absorption method, as well as process of device

A technology of desulfurization, denitrification, and membrane absorption, which is applied in separation methods, air quality improvement, chemical instruments and methods, etc., can solve the problems of limited adjustment range, difficulty in resisting impact, equipment corrosion, etc., to achieve wide application range, prevent water vapor, The effect of mitigating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

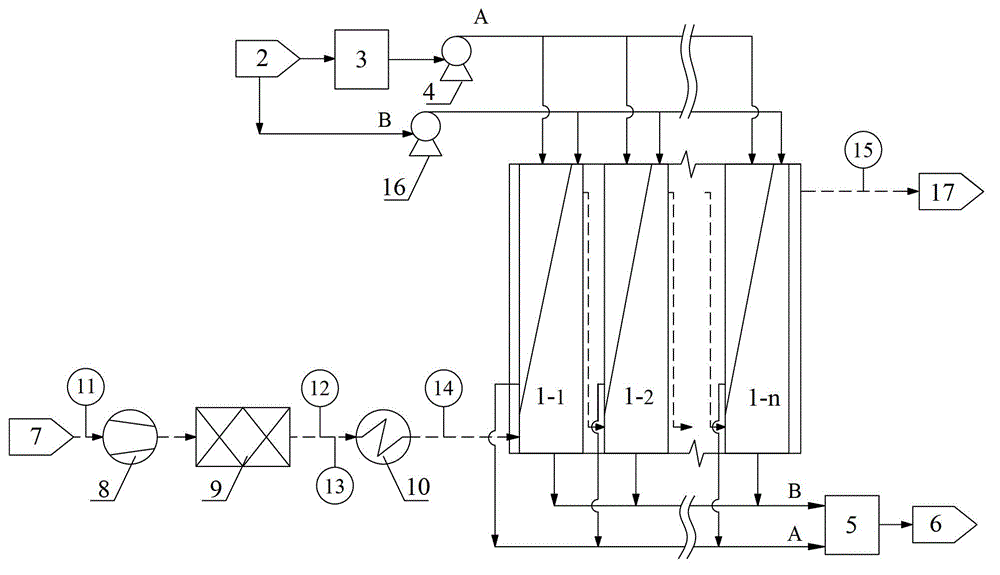

[0067] The simultaneous desulfurization and denitrification process of seawater flue gas by membrane absorption method is adopted as shown in the attached figure. The desulfurization and denitrification core part of the device is composed of three-stage box-type hydrophobic hollow fiber membrane absorbers 1-1, 1-2 and 1-3 in horizontal series. Assembled, the hollow fiber membrane filling area of each stage membrane absorber is 500m 2 , the film packing density is about 9%; the pretreated raw seawater 2 is used as the seawater-based absorbent, the pH value is 8.2, and the temperature is normal temperature; the actual coal-fired flue gas is used, and its SO 2 The concentration is 1500mg / Nm 3 , NO X Concentration 350mg / m 3 , soot concentration 100mg / Nm 3 , the temperature is 110℃~120℃, the flue gas treatment capacity is 1000Nm 3 / h. The continuous monitoring device for flue gas components is selected as SWG300 -1 Smoke is in the monitoring system. Using hydrogen peroxide...

Embodiment 2

[0069] Using the same membrane absorption treatment device and flue gas oxidant as in Example 1, the flue gas condition is SO 2 The concentration is 1500mg / Nm 3 , NO X Concentration 650mg / m 3 , soot concentration 100mg / Nm 3 , the temperature is 110℃~120℃, the flue gas treatment capacity is 1000Nm 3 / h. And using seawater-based NaClO 2 solution as an absorbent, where the additive NaClO 2 The concentration is 0.0004mol / L, the pH value is 9.0, and the temperature is normal temperature; after stable operation, the molar ratio of the amount of hydrogen peroxide sprayed into the oxidant injection device 9 to the amount of nitric oxide in the flue gas is 1.1, and the flow rate of seawater-based absorbent is 10m 3 / h, flue gas 17SO after desulfurization and denitrification 2 The concentration is 100mg / Nm 3 , NO X The concentration is 100mg / m 3 , the post-treatment of desulfurized and denitrified seawater is the same as in Example 1. Example 3:

Embodiment 3

[0070] Using the same flue gas conditions, flue gas oxidant and membrane absorption treatment device as in Example 1, the seawater-based absorbent used is composed of former seawater and NaClO 2 and HCl two additives, of which NaClO 2 The concentration is 0.0004mol / L, the concentration of HCl is 0.0001mol / L, the pH value is 6.0, and the temperature is normal temperature; after stable operation, the molar ratio of the amount of hydrogen peroxide injected into the oxidant injection device 9 to the amount of nitric oxide in the flue gas is 1.1 , the flow rate of seawater-based absorbent is 8m 3 / h, flue gas 17SO after desulfurization and denitrification 2 The concentration is 100mg / Nm 3 , NO X The concentration is 100mg / m 3 After desulfurization and denitrification, the absorption liquid and cleaning seawater are collectively discharged into the treatment tank, mixed with fresh seawater and mixed with waste alkali for neutralization, and aerated to restore the water quality, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com