Catalyst used for synthesizing methyl chloride by gas-solid phase reaction and preparation method thereof

A catalyst and gas-solid phase technology, which is applied in the field of catalyst and its preparation for the synthesis of methyl chloride by gas-solid phase method, can solve the problems of low yield of the target product, easy coking of the catalyst, poor selectivity, etc., achieve long catalyst life, promote catalytic Activity and selectivity, and the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The catalyst for the synthesis of methyl chloride by the gas-solid phase method adopts the following specific preparation steps.

[0023] a. Using the supersaturated water absorption method, measure 1g of silicon-aluminum ratio n(SiO 2 ) / n(Al 2 o 3 )=25 ZSM-5 carrier saturated water absorption is 0.4ml.

[0024] b. Pour 8ml of a solution containing 2.14g of silica sol (silica content: 28wt%) into 20g of ZSM-5 (25) carrier, stir, impregnate for 20h, dry at 120°C for 4h, and roast at 550°C for 7h , to get SiO 2 : SiO of ZSM-5 (25) = 0.03:1 (mass ratio) 2 / ZSM-5 (25), denoted as catalyst Ⅰ;

[0025] c. Immerse the catalyst I obtained above in 12ml of ethyl silicate for 16h, dry at 130°C for 3h, and roast at 550°C for 6h to obtain the catalyst II modified by ethyl silicate;

[0026] d. Pour 8ml of a solution containing 1.84g of zinc nitrate and 1.51g of copper nitrate into the catalyst II at one time, stir, impregnate for 18h, dry at 140°C for 2h, and ro...

Embodiment 2-12

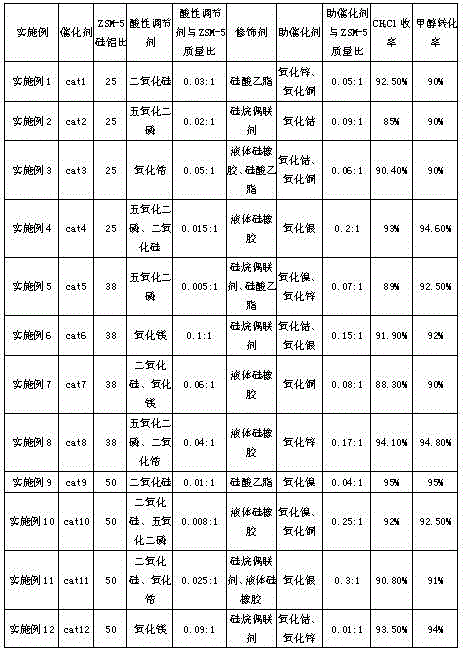

[0027] Example 2-12: The difference from Example 1 is that the silicon-aluminum ratio of the carrier ZSM-5 and the types of regulators, modifiers and co-catalysts and their mass ratios to the carrier ZSM-5 are changed to obtain different silicon-aluminum ratios And different regulators, different modifiers and different co-catalysts and catalysts with different mass ratios to the carrier ZSM-5, wherein the ZSM-5 carrier silicon-aluminum ratio ranges from 25 to 50, and the mass ratio of the co-catalyst to the carrier is 0.01- 0.3:1, the catalyst is expressed as Cat2~Cat12. When the conditioner, modifier and co-catalyst are composed of two substances respectively, their mass ratio is 1:1; the amount of acidic conditioner precursor and co-catalyst precursor in the production process is calculated according to the ratio of the final catalyst. Obtain, wherein the precursor of zinc oxide is zinc nitrate, the precursor of copper oxide is copper nitrate, the precursor of cobalt oxide ...

Embodiment 13

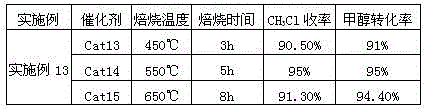

[0033] Influence of catalyst calcination temperature: Cat9 is used as the probe catalyst, which is different from Example 9 in that the calcination temperature is 450° C. to 650° C. during the preparation process of the catalyst by equal volume impregnation method, and the catalyst is recorded as Cat13 to Cat15.

[0034] According to the catalyst activity evaluation method, the catalysts Cat13-Cat15 were evaluated for activity, and the evaluation results are shown in Table 2.

[0035] Table 2: Catalyst activity corresponding to different calcination temperatures

[0036]

[0037] Table 2 lists the catalytic activity results of the catalysts prepared at different calcination temperatures. Among them, when the calcination temperature was 550 ° C, the catalyst showed higher activity, the yield of methyl chloride reached 95%, the methanol conversion rate was 95%, and no By-products, the selectivity reaches 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com