Preparation method of novel hyperbranched triazine char forming agent

A technology of hyperbranched triazine and carbon-forming agent, applied in the field of polymer materials, can solve the problems of difficulty in solvent distillation and recovery, discontinuous reaction process, poor thermal stability of products, etc., and achieve shortened reaction time, continuous reaction process, and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

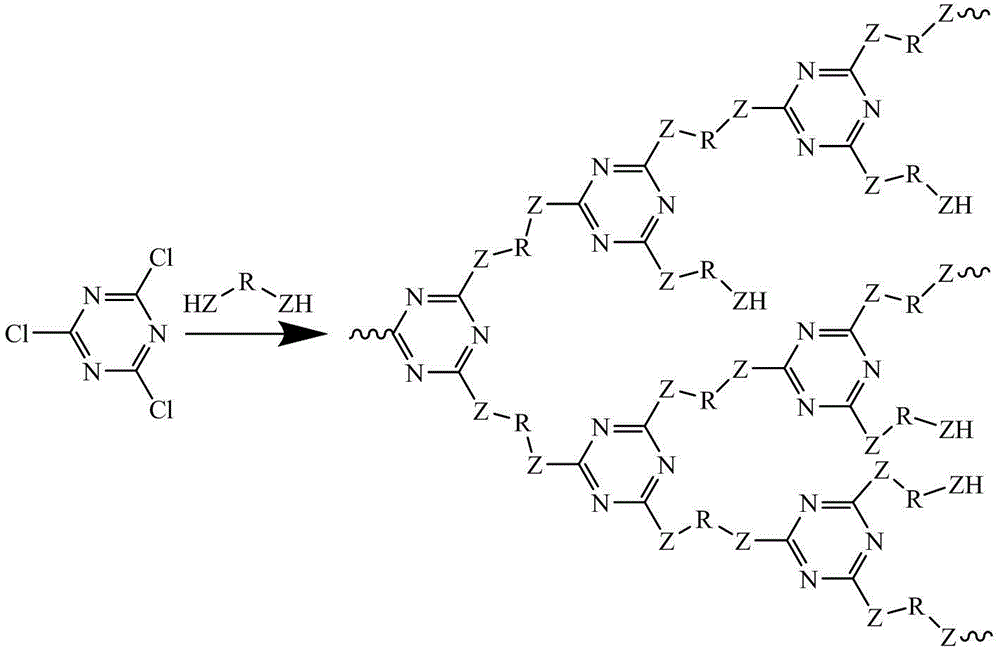

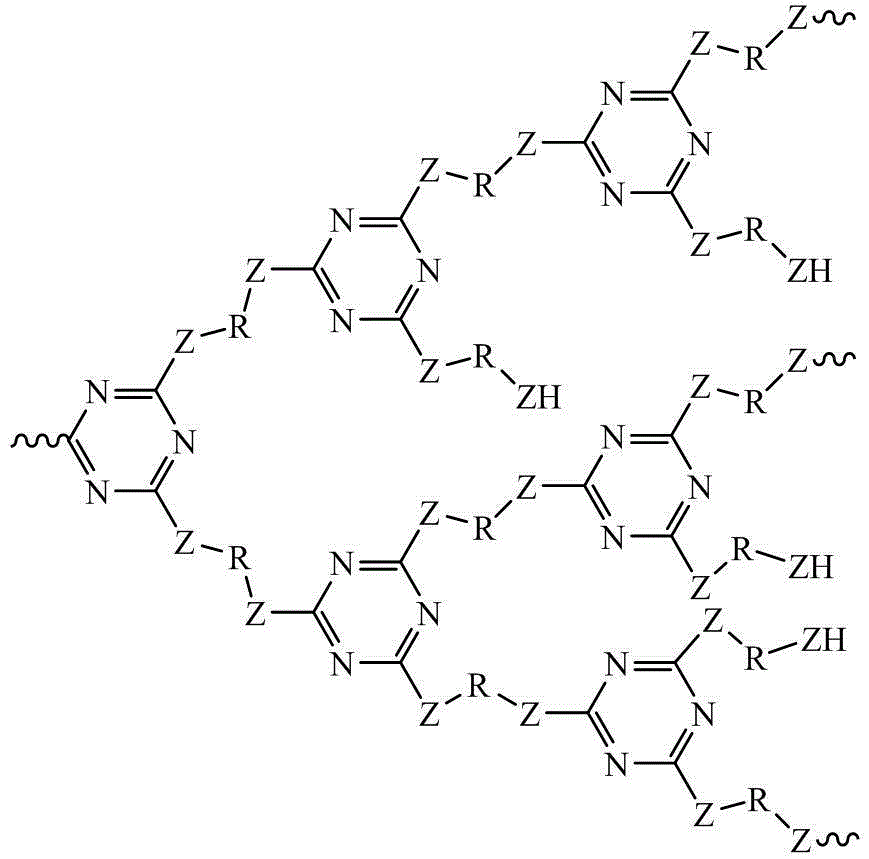

Method used

Image

Examples

Embodiment 1

[0032]Dissolve 0.52mol of piperazine in 150mL of water and add to a 500mL three-necked flask equipped with a reflux condenser, constant pressure dropping funnel, and stirrer, then dissolve 0.25mol of cyanuric chloride in 80mL of ethanol and water (vol. ratio of 4:1) into the mixed solvent, dropwise added to the system, and reacted at 0°C for 4 hours, then raised the temperature to 50°C, dissolved 0.78mol of NaOH in 80mL of water, and slowly added dropwise to the system, And react at this temperature for 6 hours, finally heat up to 95°C, react for 9 hours, stop stirring, suction filter while hot, wash with water 3 times, and vacuum dry at 80°C for 8 hours to obtain 60.13g of triazine hyperbranched charcoal agent , the productive rate is 97.4%, and the chlorine element content is 1.17%. Under a nitrogen atmosphere, the weight loss at 468°C is 1%, and the carbon content at 600°C is 42%.

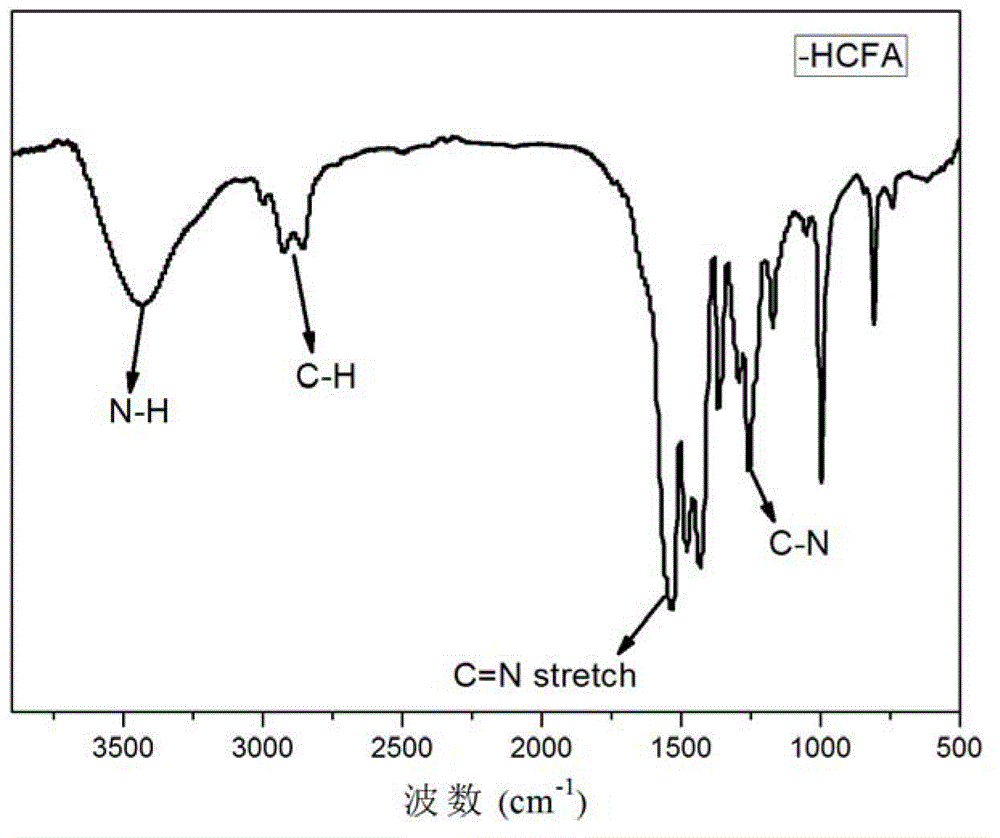

[0033] figure 1 It is the infrared spectrogram of the product in Example 1. As can be seen...

Embodiment 2

[0036] Dissolve 0.5mol of ethylenediamine in 50mL of water into a 500mL three-necked flask equipped with a reflux condenser, a constant pressure dropping funnel, and a stirrer, then dissolve 0.25mol of cyanuric chloride in 25mL of ethanol, and gradually Add dropwise to the system, and react at 10°C for 1 hour, then raise the temperature to 70°C, add 0.4mol of Na 2 CO 3 Dissolve in 40mL of water, slowly drop into the system, and react at this temperature for 3 hours, finally raise the temperature to 150°C, react for 6 hours, stop stirring, suction filter while hot, wash with water 3 times, and dry at 100°C for 2 hours , 46.5 g of triazine hyperbranched charcoal agent was obtained, the yield was 95.9%, and the content of chlorine element was 0.95%. The elemental analysis results of the product in Example 2 show that in the triazine hyperbranched charcoal agent, the theoretical percentages of C, N, and H are respectively 43.30%, 50.52%, and 6.19%, while the measured values are...

Embodiment 3

[0038] Dissolve 0.15mol of N-aminoethylpiperazine in a mixture of 300mL of water and ethanol (4:1 by volume) and add it to a 1000mL three-necked flask equipped with a reflux condenser, a constant pressure dropping funnel, and a stirrer. Then, dissolve 0.05mol of cyanuric chloride in 100mL of water, add dropwise to the system, and react at 5°C for 3 hours, then raise the temperature to 30°C, dissolve 0.18mol of KOH in 180mL of water, slowly add dropwise into the system, and react at this temperature for 8 hours, and finally raise the temperature to 90°C, react for 10 hours, stop stirring, suction filter while hot, wash with water 3 times, and vacuum dry at 50°C for 10 hours to obtain a triazine-based hyperbranched charcoal Agent is 15.56g, and productive rate is 93.45%, and chlorine element content is 1.56%. The elemental analysis results of the product in Example 3 show that the theoretical percentages of C, N, and H in the triazine hyperbranched charcoal agent are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com