Hydrothermal preparation method of nano-titania coating on surface of magnesium alloy intravascular stent

A nano-titanium oxide, magnesium alloy blood vessel technology, applied in metal material coating process, coating and other directions, can solve the problem that titanium oxide coating does not have specific surface area and porosity, magnetron sputtering equipment is complex and expensive, and it is difficult to achieve load-bearing. drug function and other issues, to achieve the effects of good blood compatibility, strong binding force, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

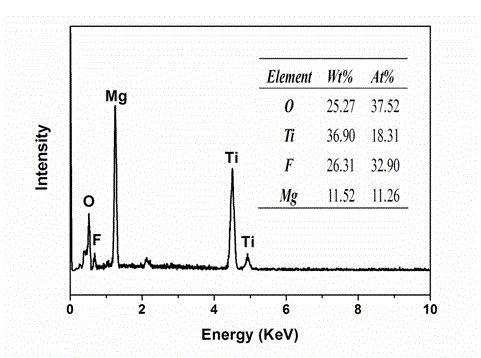

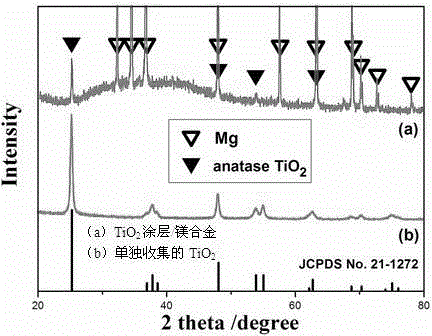

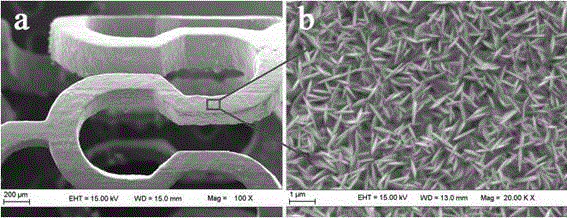

[0021] On the surface of the electropolished Mg-Zn-based alloy vascular stent, a nano-flaky titanium oxide coating is prepared, and the preparation steps are as follows:

[0022] (1) Drop hydrofluoric acid into absolute ethanol, stir until mixed evenly, then add tetrabutyl titanate, stir until mixed evenly to form solution A, and the molar concentration of hydrofluoric acid in solution A is 0.2mol· L -1 , the molar concentration of tetrabutyl titanate in solution A is 0.1mol L -1 ;

[0023] (2) Stir and mix ammonium fluoride and deionized water evenly to form solution B, the molar concentration of ammonium fluoride in solution B is 0.2mol L -1 , mix and stir solution A and solution B evenly to form solution C, the volume ratio of solution A and solution B is 60:1, and the molar concentration of ammonium fluoride in solution C is 3.3mmol L -1 ;

[0024] (3) Put the electropolished magnesium alloy stent into solution C, and react with it under the condition of 170°C for 10 h...

Embodiment 2

[0029] On the surface of the electropolished Mg-Zn-based alloy vascular stent, a nano-flaky titanium oxide coating is prepared, and the preparation steps are as follows:

[0030] (1) Drop hydrofluoric acid into absolute ethanol, stir until mixed evenly, then add tetrabutyl titanate, stir until mixed evenly to form solution A, and the molar concentration of hydrofluoric acid in solution A is 0.1mol· L -1 , the molar concentration of tetrabutyl titanate in solution A is 0.2mol L -1 ;

[0031] (2) Stir and mix sodium fluoride and deionized water evenly to form solution B. The molar concentration of sodium fluoride in solution B is 0.1mol L -1 , mix and stir solution A and solution B evenly to form solution C, the volume ratio of solution A and solution B is 30:1, and the molar concentration of sodium fluoride in solution C is 3.3mmol L -1 ;

[0032] (3) Put the electropolished magnesium alloy stent into the solution C, and react it with water heat at 100°C for 24 hours; take ...

Embodiment 3

[0034] Prepare a nano-sheet titanium oxide coating on the surface of the electropolished Mg-Re-based alloy vascular stent, and the preparation steps are as follows:

[0035] (1) Drop hydrofluoric acid into absolute ethanol, stir until it is evenly mixed, then add tetrabutyl titanate, and stir until it is evenly mixed to form solution A. The molar concentration of hydrofluoric acid in solution A is 0.4mol· L -1 , the molar concentration of tetrabutyl titanate in solution A is 0.3mol L -1 ;

[0036] (2) Stir and mix potassium fluoride and deionized water evenly to form solution B. The molar concentration of potassium fluoride in solution B is 0.4mol L -1 , mix and stir solution A and solution B evenly to form solution C, the volume ratio of solution A and solution B is 150:1, and the molar concentration of potassium fluoride in solution C is 2.6mmol L -1 ;

[0037] (3) Put the electrolytically polished magnesium alloy stent into solution C, and react it with water heat at 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com