Compounding method and application of soil conditioner

A soil improver and saline-alkali soil technology, which is applied in the field of solid waste treatment, can solve the problems of phosphogypsum environmental pollution and low value-added use of distiller's grains, so as to increase output value and economic benefits, increase dry matter content, and improve soil fertility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

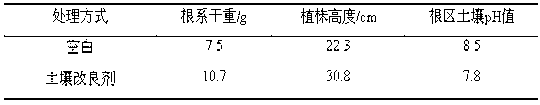

Embodiment 1

[0019] 1. Dry the waste residue phosphogypsum from Kunming Changqingshu Company at 60°C for 10 hours, and crush it to 200 mesh after drying to obtain pretreated phosphogypsum;

[0020] 2. Dried the waste fungus bag from Kunming Edible Fungi Research Institute (the waste fungus bag produced by cultivating Flammulina velutipes using conventional methods) and the distiller's grains from Kunming winery until the water content was 12% and then pulverized. The pulverized 100 1 kg of distiller's grains and 5 kg of waste bacteria bags are mixed evenly and fermented naturally. The fermentation conditions are as follows: control the fermentation water to 50%, and the stacking height is 0.7m. Cover with film to facilitate heat preservation, reduce water evaporation, turn over once every 3 days, and ferment for 10 days;

[0021] 3. Mix 1,000 kg of pretreated phosphogypsum with the fermented distiller's grains waste bacteria bag evenly, add water to adjust the water content to 35%, stack a...

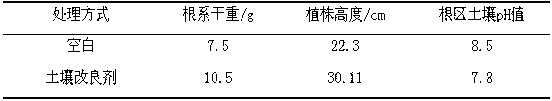

Embodiment 2

[0029] 1. Dry the waste residue phosphogypsum from Kunming Changqingshu Company at 80°C for 5 hours, and crush it to 250 mesh after drying to obtain pretreated phosphogypsum;

[0030] 2. Dried the waste fungus bag from the Kunming Edible Fungi Research Institute (the waste fungus bag produced by cultivating shiitake mushrooms by conventional methods) and the distiller's grains from the Kunming winery until the water content was 14%, and then crushed. The crushed 100 kg The distiller's grains and 10 kg of waste bacteria bags are mixed evenly and fermented naturally. The fermentation conditions are: control the fermentation water to 55%, and the stacking height is 0.9m. Thin film is used to keep warm and reduce water evaporation, turn over every 5 days, and the fermentation time is 15 days;

[0031] 3. Mix 1,000 kg of pretreated phosphogypsum with the fermented distiller's grains waste bacteria bag evenly, add water to adjust the water content to 37%, pile up at room temperature...

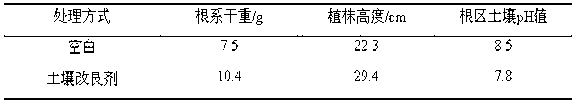

Embodiment 3

[0039] 1. Dry the waste residue phosphogypsum from Kunming Changqingshu Company at 65°C for 8 hours, and crush it to 300 mesh after drying to obtain pretreated phosphogypsum;

[0040]2. Dried the waste fungus bag from Kunming Edible Fungi Research Institute (a mixture of the waste fungus bag produced after cultivating Flammulina velutipes and Lentinus edodes using conventional methods) and the distiller's grains from Kunming winery until the water content was 16% and then pulverized. 500 kg of crushed distiller's grains and 50 kg of waste bacteria bags are mixed evenly and fermented naturally. The fermentation conditions are: control the fermentation water to 60%, and the stacking height is 1.1m. Microbial reproduction, cover with film to facilitate heat preservation, reduce water evaporation, turn over every 4 days, and the fermentation time is 20 days;

[0041] 3. Mix 1,000 kg of pretreated phosphogypsum with the fermented distiller's grains waste bacteria bag evenly, add wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com