Copper indium gallium selenium solar battery device and preparing method thereof

A technology of copper indium gallium selenide and solar cells, which is applied to electrical components, semiconductor devices, circuits, etc., can solve the problems of increased carrier recombination, poor film crystal quality, and many defects, and achieve improved roughness and good crystal quality , not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

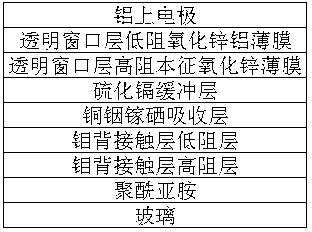

[0044] A copper indium gallium selenide solar cell device is a copper indium gallium selenide solar cell based on a polyimide film-soda glass composite substrate, such as figure 1 As shown, it consists of glass, polyimide, molybdenum back contact layer, copper indium gallium selenide absorber layer, cadmium sulfide buffer layer, transparent window layer with high resistance intrinsic zinc oxide film, transparent window layer with low resistance zinc aluminum oxide film and aluminum The upper electrode is composed and forms a laminated structure, wherein the substrate is composed of soda glass and a polyimide film grown on its surface, the thickness of the soda glass is 2 mm, and the thickness of the polyimide film is 25 μm; the molybdenum back contact layer includes a high The resistance layer film and the low resistance layer film, wherein the thickness of the high resistance layer film is 100nm, and the thickness of the low resistance layer film is 600nm; the chemical molecul...

Embodiment 2

[0071] A copper indium gallium selenide solar cell device is a copper indium gallium selenide solar cell based on a polyimide film-soda glass composite substrate, such as figure 1 As shown, it consists of glass, polyimide, molybdenum back contact layer, copper indium gallium selenide absorber layer, cadmium sulfide buffer layer, transparent window layer with high resistance intrinsic zinc oxide film, transparent window layer with low resistance zinc aluminum oxide film and aluminum The upper electrode is composed and forms a laminated structure, wherein the substrate is composed of soda glass and polyimide film grown on its surface, the thickness of the soda glass is 2mm, and the thickness of the polyimide film is 30μm; the molybdenum back contact layer includes high The resistance layer film and the low resistance layer film, wherein the thickness of the high resistance layer film is 100nm, and the thickness of the low resistance layer film is 700nm; the chemical molecular for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com