Catalyst for one step conversion of cellulose into sorbitol

A catalyst and functionalization technology, applied in clean catalysis and green fields, can solve the problems of increasing safety hazards and increasing costs, and achieve the effects of reduced separation, simple preparation, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

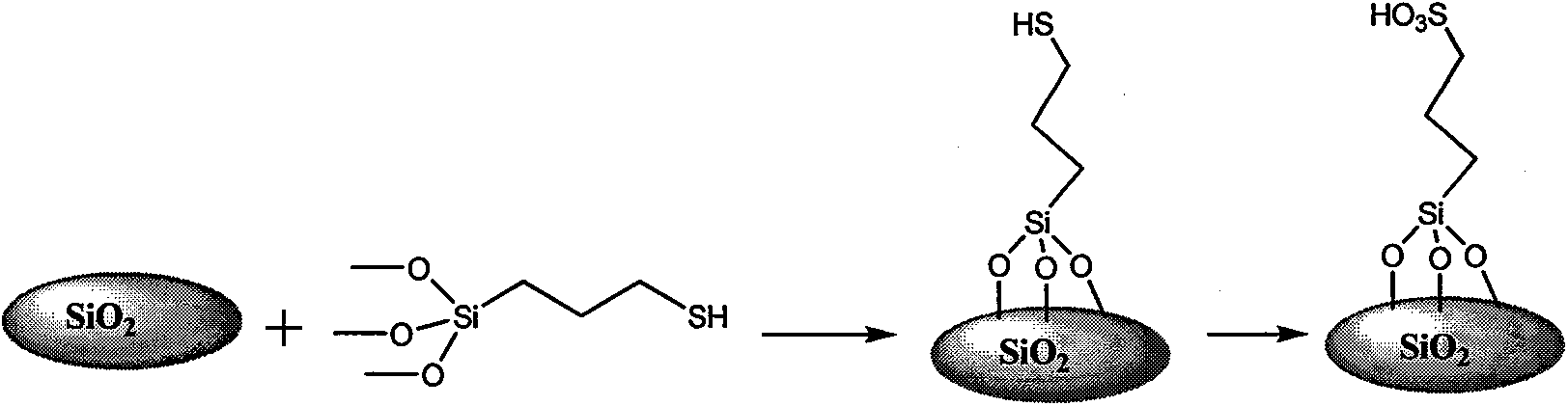

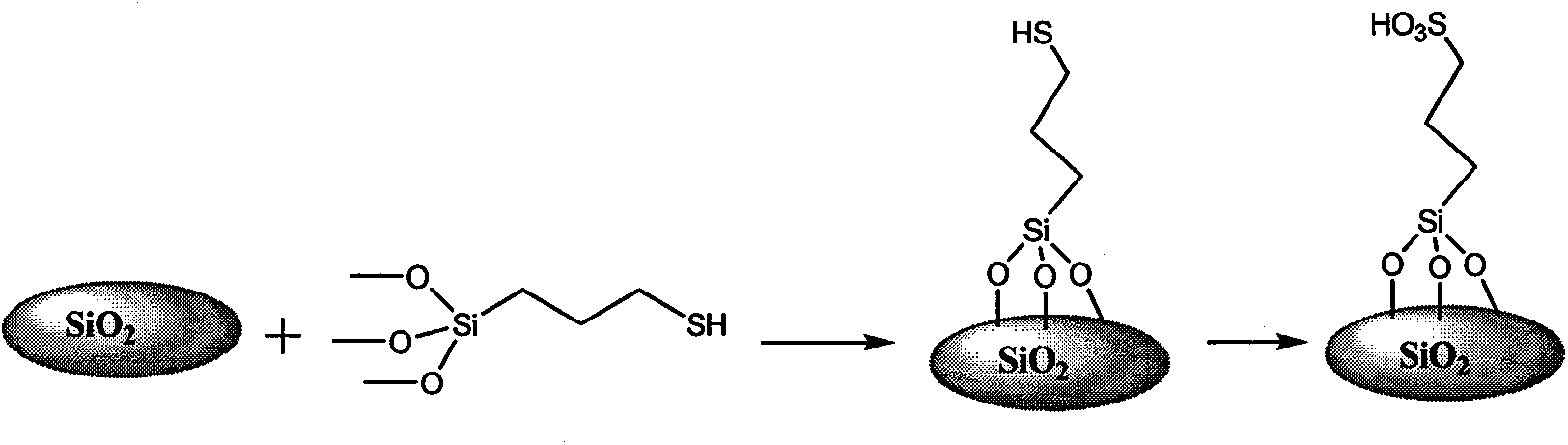

[0019] Example 1: Preparation of ruthenium-supported sulfonic acid functionalized silica catalyst

[0020] Step 1. Preparation of mercapto-functionalized silica gel: reflux and stir 10 g of silica gel and 1 mmol of 3-mercaptopropyltrimethoxysilane in dry toluene for 18 h. The obtained solid material was washed with hot toluene in a Soxhlet extractor for 12 h, and finally the washed solid material was dried in a vacuum oven at 110° C. overnight. A mercapto-functionalized silica material is obtained.

[0021] Step 2. Preparation of sulfonic acid-functionalized silica gel: take 5 g of the previously prepared mercapto-functionalized silica material, add 50 mL of 30% H 2 o 2 Hydrogen peroxide, 2 drops of concentrated sulfuric acid and 15 mL of methanol were stirred at room temperature for 12 h (oxidation of mercapto functional groups to sulfonic acid functional groups). The above mixture was filtered with suction, and the filter cake was washed with 50 mL of deionized water. In...

example 2

[0023] Example 2: Preparation of ruthenium-supported sulfonic acid functionalized silica catalyst

[0024] Step 1. Preparation of mercapto-functionalized silica gel: reflux and stir 10 g of silica gel and 3 mmol of 3-mercaptopropyltrimethoxysilane in dry toluene for 18 h. The obtained solid material was washed with hot toluene in a Soxhlet extractor for 12 h, and finally the washed solid material was dried in a vacuum oven at 110° C. overnight. A mercapto-functionalized silica material is obtained.

[0025] Step 2. Preparation of sulfonic acid-functionalized silica gel: take 5 g of the previously prepared mercapto-functionalized silica material, add 50 mL of 30% H 2 o 2 Hydrogen peroxide, 2 drops of concentrated sulfuric acid and 15 mL of methanol were stirred at room temperature for 12 h (oxidation of mercapto functional groups to sulfonic acid functional groups). The above mixture was filtered with suction, and the filter cake was washed with 50 mL of deionized water. In...

example 3

[0027] Example 3: Preparation of ruthenium-supported sulfonic acid functionalized silica catalyst

[0028]Step 1. Preparation of mercapto-functionalized silica gel: reflux and stir 10 g of silica gel and 7 mmol of 3-mercaptopropyltrimethoxysilane in dry toluene for 18 h. The obtained solid material was washed with hot toluene in a Soxhlet extractor for 12 h, and finally the washed solid material was dried in a vacuum oven at 110° C. overnight. A mercapto-functionalized silica material is obtained.

[0029] Step 2. Preparation of sulfonic acid-functionalized silica gel: take 5 g of the previously prepared mercapto-functionalized silica material, add 50 mL of 30% H 2 o 2 Hydrogen peroxide, 2 drops of concentrated sulfuric acid and 15 mL of methanol were stirred at room temperature for 12 h (oxidation of mercapto functional groups to sulfonic acid functional groups). The above mixture was filtered with suction, and the filter cake was washed with 50 mL of deionized water. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com