Slagging resistance method for mixed burning of biomass and sludge

A mixed combustion and biomass technology, applied in the direction of combustion method, combustion type, dehydration/drying/thickened sludge treatment, etc., can solve the problems of waste of resources, environmental pollution, etc., and achieve the effect of avoiding secondary pollution and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

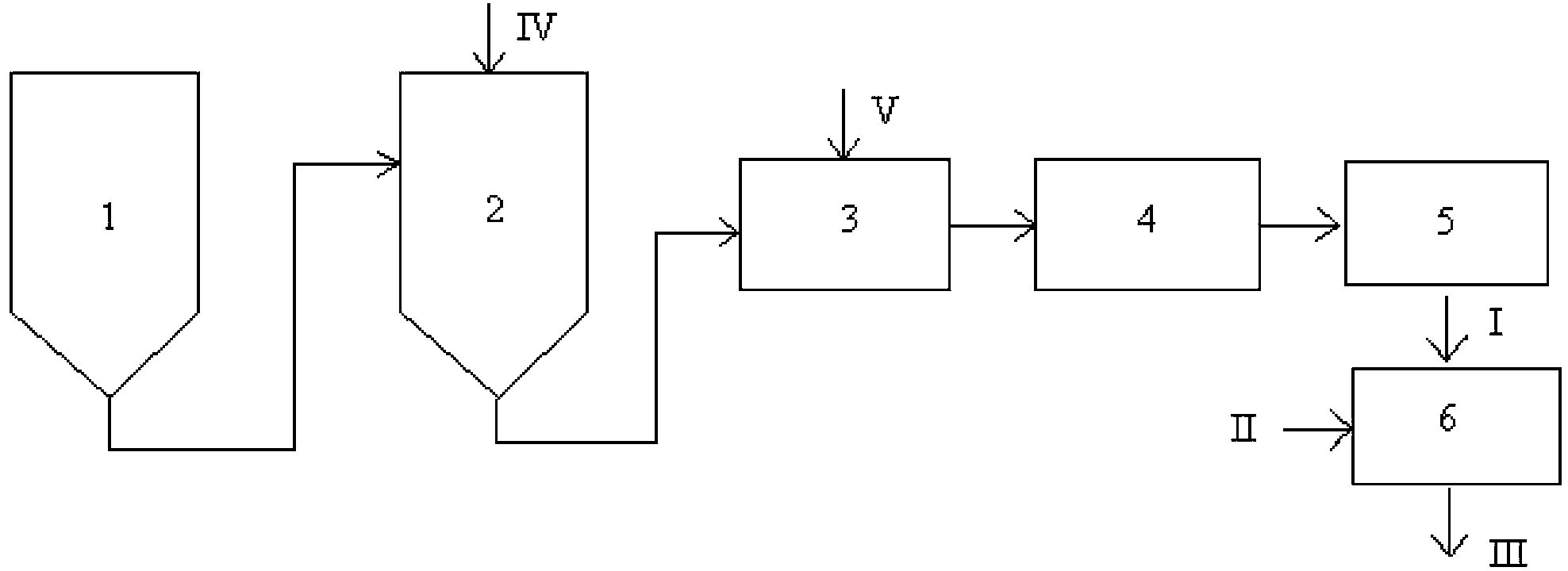

Image

Examples

Embodiment 1

[0021] The sludge discharged from the secondary settling tank enters the concentration flocculation system and then adds aluminum sulfate with a weight ratio of 1:500 to the dry sludge as a flocculant to flocculate the sludge. CaO with a weight ratio of 1:10 is used as a conditioner to condition the sludge, and then dehydrate the sludge with dehydration equipment such as a plate and frame filter press. The dehydrated sludge is dried until the water content is 30 %, enter the crushing system for crushing, and the crushed sludge and biomass are mixed at a mass ratio of 1:1 to prepare shaped fuel and sent to the biomass boiler for combustion. On the basis of sludge disposal, this method recovers heat, and at the same time, the anti-slagging elements contained in the sludge increase the ash melting point of biomass combustion. After half a year of continuous operation, the boiler has no slagging phenomenon.

Embodiment 2

[0023] After the sludge discharged from the secondary sedimentation tank enters the thickening and flocculation system, polyaluminum chloride with a weight ratio of 1:300 to the dry sludge is added as a flocculant to flocculate the sludge, and the sludge obtained by flocculation and concentration enters the dehydration system and then added CaO with a weight ratio of 1:100 to the dry sludge is used as a conditioner to condition the sludge, and then the sludge is dehydrated by dehydration equipment such as a plate and frame filter press, and the dehydrated sludge is dried to moisture After it is below 30%, it enters the crushing system for crushing. The crushed sludge and biomass are mixed at a mass ratio of 1:5 to prepare shaped fuel and sent to the biomass boiler for combustion. After being blended with sludge, the slagging of the biomass boiler has been significantly improved compared with burning biomass only after half a year of continuous operation.

Embodiment 3

[0025] After the sludge discharged from the secondary sedimentation tank enters the thickening and flocculation system, polyaluminum magnesium silicate with a weight ratio of 1:200 to the dry sludge is added as a flocculant to carry out flocculation treatment on the sludge, and the sludge obtained by flocculation and concentration enters the dehydration system Adding CaO with a weight-to-weight ratio of 1:50 as a conditioner to the sludge is used as a conditioner to condition the sludge, and then use dehydration equipment such as a plate and frame filter press to dehydrate the sludge, and the dehydrated sludge is dried to After the moisture is below 30%, it enters the crushing system for crushing. The crushed sludge and biomass are mixed at a mass ratio of 5:1 and then directly sent to the biomass boiler for combustion. The blending of sludge in the biomass combustion process not only solves the problem of sludge disposal in nearby sewage treatment plants, but also avoids the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com