Tetrafluoroethylene-propylene rubber/silicone rubber/chloroprene rubber composite sealing pad and preparation method thereof

A technology of tetrapropylene fluorine rubber and composite gasket, applied in the field of gasket and its preparation, can solve the problems of rubber gasket's sealing performance, compression permanent deformation resilience can not meet the actual requirements, etc., achieve small changes in volume and hardness, not easy Crack, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

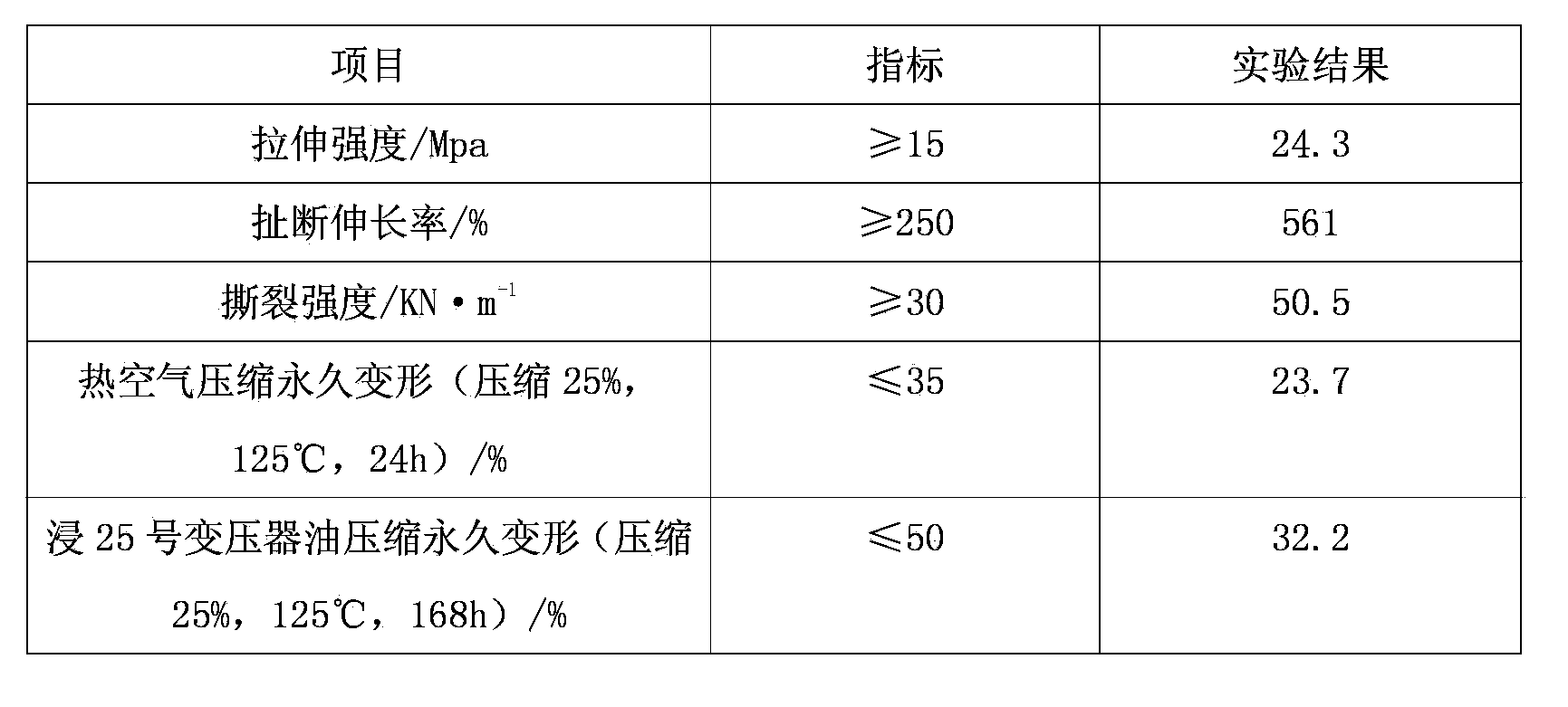

Examples

Embodiment Construction

[0015] A tetrapropylene fluororubber / silicone rubber / neoprene composite gasket, made of the following raw materials in weight (kg): tetrapropylene fluororubber (TP-2) 48, silicone rubber (SR-315) 26, neoprene Rubber (CR2442) 15, magnesium methacrylate 4, tris(2,3-dichloropropyl) phosphate 6, decabromodiphenylethane 4, 2, 4-dichlorobenzoyl peroxide 2, N, N'-m-phenylene bismaleimide 1.5, C5 petroleum resin 4, fumed silica 12, modified fluorite powder 10, nano silicon nitride 4, trimethylolpropane trimethacrylate 2.5, hard Lead fatty acid 1.5, zinc oxide 2, anti-scorch agent CTP 0.5, anti-aging agent 4020 1.5, accelerator TMTD 3, accelerator NS 3;

[0016] The preparation method of the modified fluorite powder is as follows: crush the fluorite to below 15 μm, add diatomite equivalent to 8% of the fluorite weight, 4% sodium tripolyphosphate, 2% plant ash, and 3% nano-carbon , 5% simethicone oil, grind at 3000 r / min for 20 minutes, dry, then add an appropriate amount of water to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com