Probiotics microcapsule product and preparation and application thereof

A technology of microcapsules and probiotics, applied in the field of probiotic microcapsules products, can solve the problems of limited gastric acid barrier effect, achieve high embedding rate, high activity, and significant tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Calcium alginate gel microspheres embedded with Lactobacillus rhamnosus were prepared by co-directional / axial flow technology under sterile conditions, and the cell seeding density was 1×10 7 / ml calcium alginate gel microspheres.

[0034] 2) Microspheres are immersed in chitosan (chitosan molecular weight 50kDa, deacetylation degree 98%) in the solution (concentration 5g / L), the volume ratio of microspheres and chitosan solution is 1: 10, react for 20 minutes, physiological After washing with brine, AC microencapsulated Lactobacillus was prepared.

[0035] 3) The AC microcapsules were liquefied with 55 mM sodium citrate solution for 10 minutes to prepare AC microencapsulated Lactobacillus in a liquid environment inside.

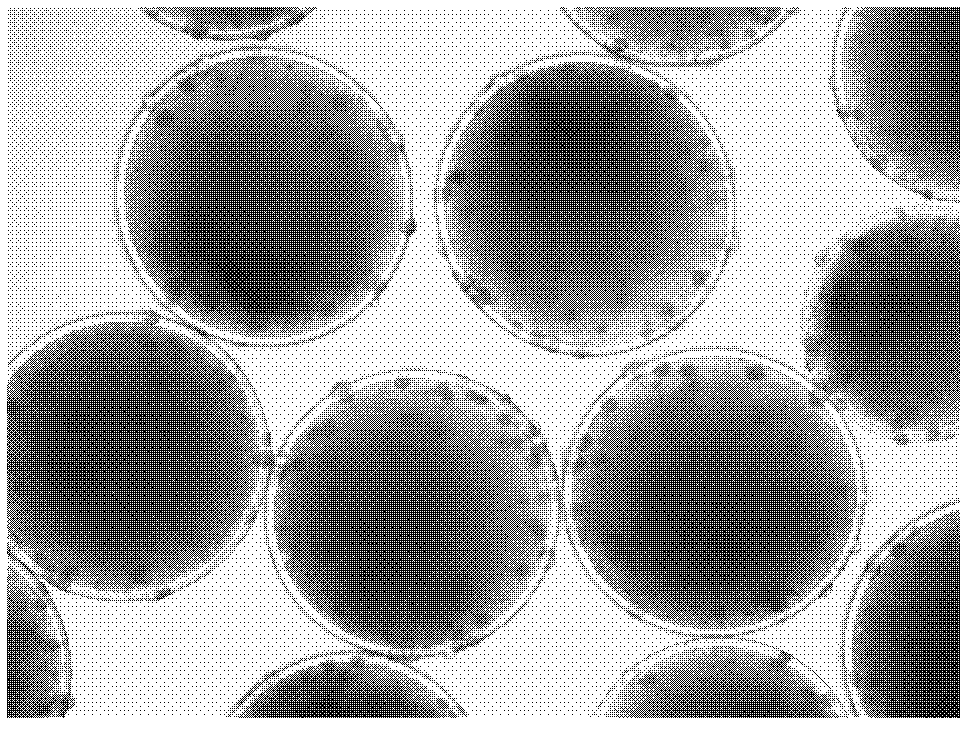

[0036] 4) Put AC microencapsulated Lactobacillus into MRS basal medium, culture at 37°C for 24 hours until the end of the logarithmic growth phase, and the cell density in the microcapsules reaches 5×10 11 / ml microcapsules ( figure 1 ).

[003...

Embodiment 2

[0041] 1) Under sterile conditions, in an anaerobic workstation, calcium alginate gel microspheres embedded with Bifidobacterium longum were prepared by emulsification-internal gelation technology, and the cell seeding density was 1×10 7 / ml calcium alginate gel microspheres.

[0042] 2) Microspheres are immersed in chitosan (chitosan molecular weight 100kDa, deacetylation degree 90%) in the solution (concentration 2g / L), the volume ratio of microspheres and chitosan solution is 1: 10, react for 20 minutes, physiological After washing with brine, AC microencapsulated Bifidobacterium longum was prepared.

[0043] 3) The AC microcapsules were liquefied with 55 mM sodium citrate solution for 10 minutes to prepare AC microencapsulated Bifidobacterium longum in a liquid environment inside.

[0044] 4) Put AC microencapsulated Bifidobacterium longum into the culture medium (formula (by weight): 1.67% soybean peptone, 0.83% casein peptone, 1.0% lactose, 0.5% yeast extract powder, 0....

Embodiment 3

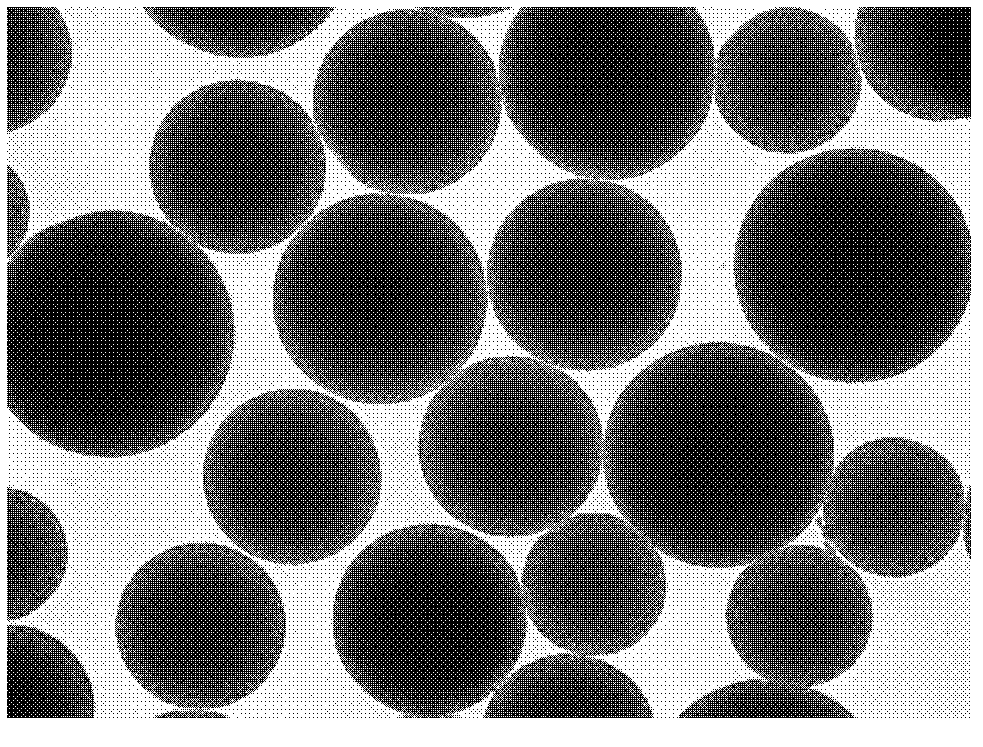

[0049] 1) Calcium alginate gel microspheres embedded with probiotic yeast were prepared by emulsification-external gelation technology under sterile conditions, and the cell embedding density was 2×10 9 / ml calcium alginate gel microspheres ( image 3 ).

[0050] 2) Microspheres are immersed in chitosan (chitosan molecular weight 20kDa, deacetylation degree 98%) in the solution (concentration 5g / L), the volume ratio of microspheres and chitosan solution is 1: 10, react for 20 minutes, physiological After washing with brine, AC microencapsulated yeast was prepared.

[0051] 3) Add protective agent ((by weight) 3% galactose, 8% skimmed milk powder, 5% glycerol, 1.5% sodium glutamate (W / V, g / ml) to the above-mentioned microcapsules, and the balance is water ), after freeze-drying (-40°C, 12 hours), probiotic microcapsule particles were obtained, with an average particle size of 100 microns.

[0052] 4) After the above-mentioned dried microcapsules were treated with simulated g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com