Fibroin-base artificial ligament repair material and preparation method thereof

An artificial ligament and repair material technology, applied in medical science, prosthesis, etc., can solve the problems of poor tissue compatibility, reactive exudation, rapid degeneration of carbon fiber ligament, etc., and achieve excellent biocompatibility, preparation Simple method and beneficial effect on cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

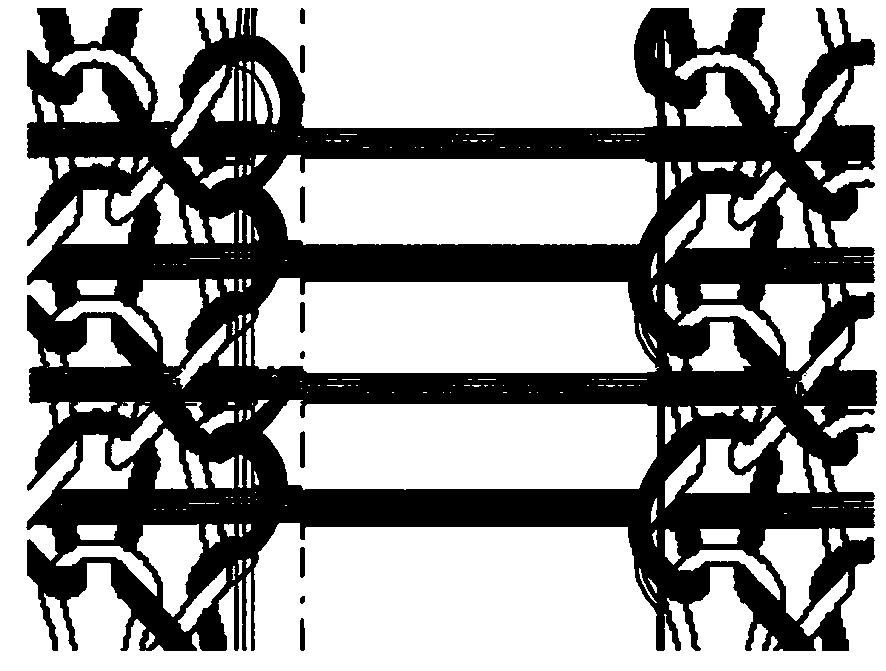

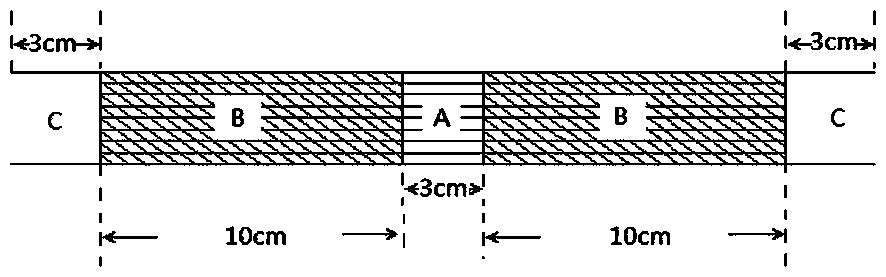

[0043] (1) The weaving of the natural mulberry silk warp knitted scaffold material is woven by the RSM biaxial weft-inserted warp knitting machine. The weaving process and threading process are as follows:

[0044] a. Organization process:

[0045] GB1: 2-3 / 3-2 / 1-0 / 2-3 / 1-0 / 0-1 / 2-3 / 1-0 / /

[0046] GB2: 1-0 / 0-1 / / ×4

[0047] b. Yarn threading process:

[0048] GB1: full wear;

[0049] GB2: full wear

[0050] c. Machine number: E12;

[0051] (2) Degumming, dissolving, and dialysis of natural mulberry silk to form a silk fibroin aqueous solution with a mass fraction of 5%, placing it in a PEG solution and stirring at a low speed to concentrate to a silk fibroin aqueous solution with a mass fraction of 22%; The temperature is about 25 °C, wet spinning is carried out within a storage time of 5d, the nascent silk fibroin fibers are soaked in absolute ethanol, sealed, placed at room temperature for 24 h, and drawn in deionized water above 60 °C , the nascent fibers were drawn twic...

Embodiment 2

[0057] (1) The weaving of the warp-knitted stent material is the same as that of Example 1;

[0058] (2) Degumming, dissolving, and dialysis of natural mulberry silk to form a silk fibroin aqueous solution with a mass fraction of 5%, placing it in a PEG solution and stirring at a low speed to concentrate to a silk fibroin aqueous solution with a mass fraction of 27%; The temperature is about 25 °C, wet spinning is carried out within the storage time of 3d, the nascent silk fibroin fibers are soaked in absolute ethanol, sealed, placed at room temperature for 24 h, and drawn in deionized water above 60 °C , the nascent fibers were drawn twice and heat-set at 120 °C for 30 min. The nascent silk fibroin fibers were placed in EDC / NHS (wt / wt=2 / 1) and added to ethanol / water (V C2H5OH / V H2O = 90 / 10) in a cross-linking solution with a mass fraction of 4.5% for 24 h, stretched in deionized water above 60 °C, and then heat-set at 120 °C for 30 min to obtain EDC / NHS cross-linking The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com