A liquid crystal polyester composition and a molded body formed by the same

A technology of liquid crystal polyester and composition, which is applied in the field of liquid crystal polyester composition and molded body formed from the composition, which can solve problems such as poor appearance, easy to be obvious, color spots, etc., and achieve the reduction of color change, durability High foaming property and maintenance of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0116] Add 994.5 g (7.2 moles) of p-hydroxybenzoic acid, 299.1 g (1.8 moles) of terephthalic acid, and 99.7g (0.6 mol), 446.9g (2.4 mol) of 4,4'-dihydroxybiphenyl, 1347.6g (13.2 mol) of acetic anhydride and 0.2g of 1-methylimidazole, while stirring under nitrogen flow, use The temperature was raised from room temperature to 150° C. in 30 minutes, and refluxed at 150° C. for 1 hour. Next, 0.9 g of 1-methylimidazole was added, and while distilling off by-produced acetic acid and unreacted acetic anhydride, the temperature was raised from 150°C to 320°C over 2 hours and 50 minutes, and held until a rise in torque was confirmed at 320°C After that, the reaction mixture was taken out from the reactor and cooled to room temperature. The obtained solid was pulverized with a pulverizer to obtain a powdery prepolymer. The prepolymer was heated from room temperature to 250°C in nitrogen atmosphere for 1 hour, heated from 250°C to 285°C in 5 hours, kept at 285°C for 3 hours for solid-s...

Embodiment 1~8、 comparative example 1~8

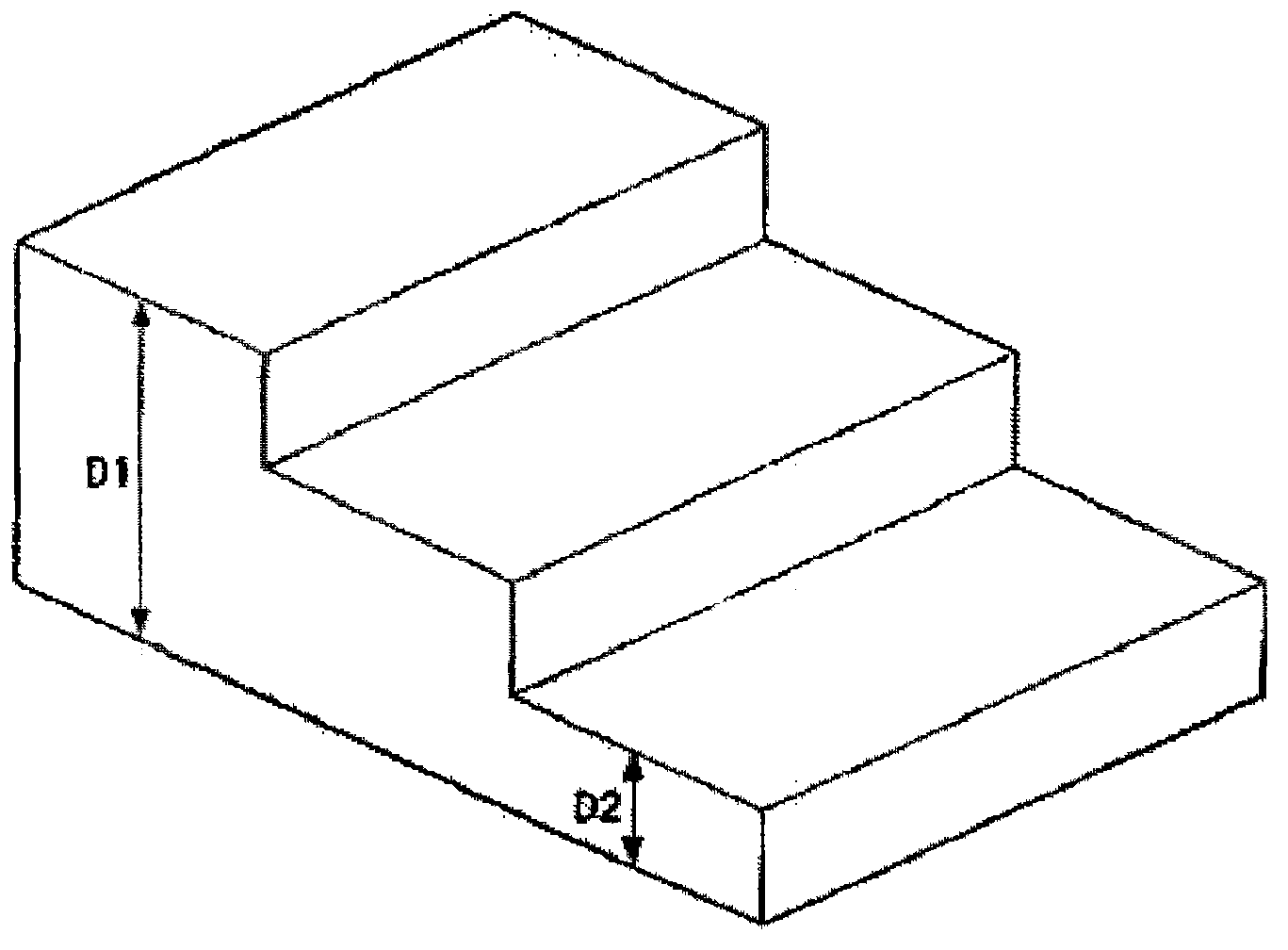

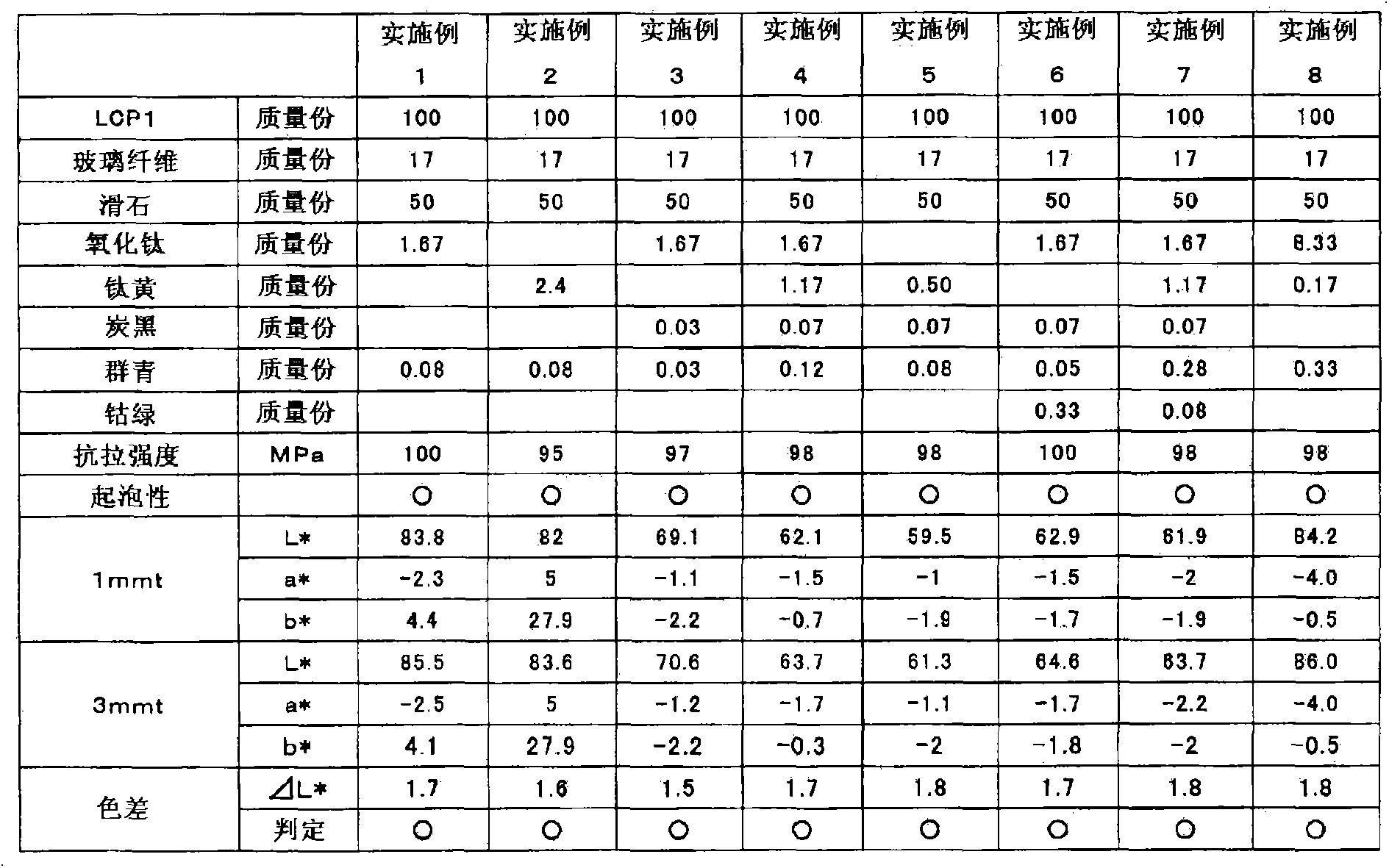

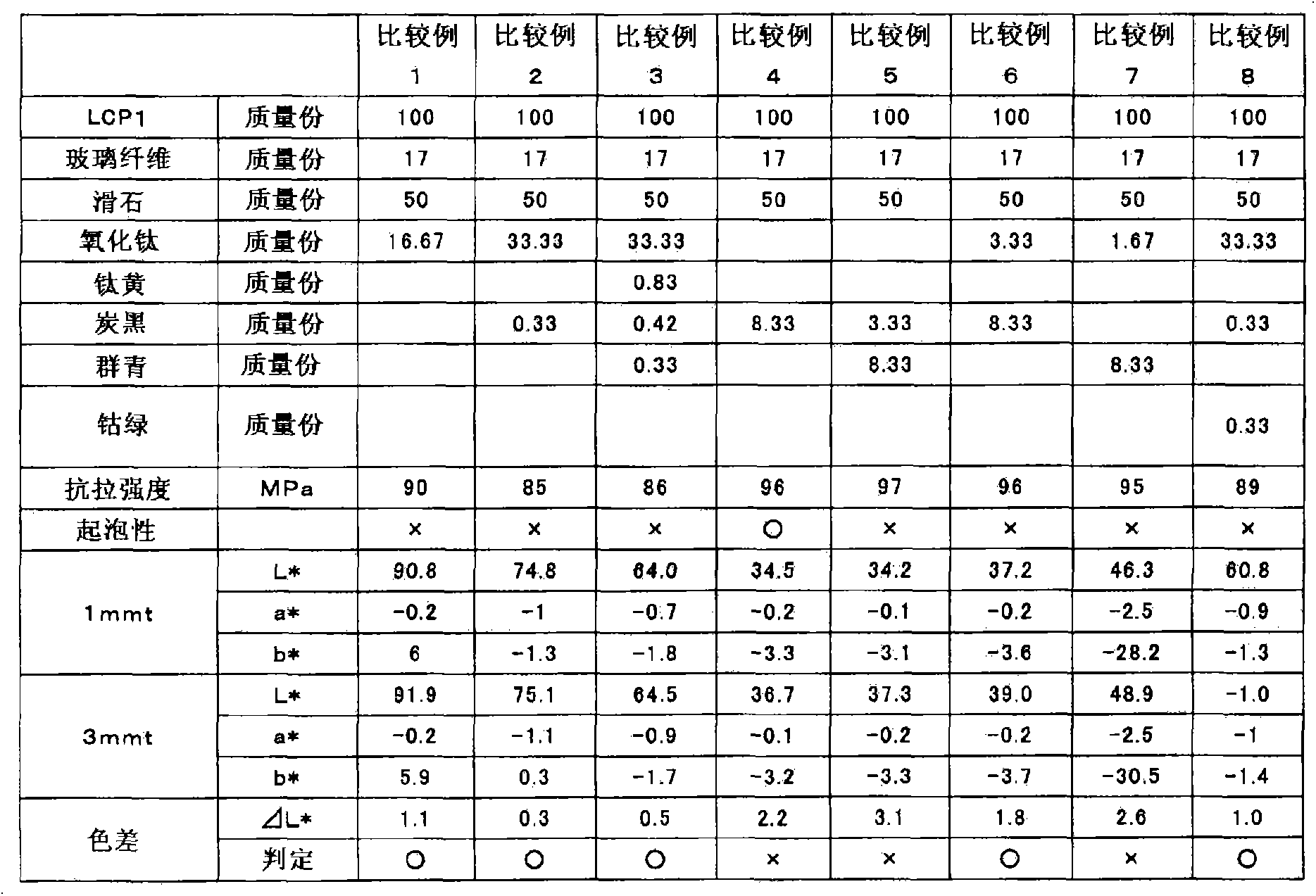

[0119]The liquid crystal polyester obtained in Production Example 1 was blended with the following fillers and coloring materials at the ratios shown in Tables 1 and 2, and a twin-screw extruder PCM30 manufactured by Ikegai Iron Works Co., Ltd. was used. Granulation was carried out at 340° C. to obtain a liquid crystal polyester composition. The obtained composition was molded at 350° C. using an injection molding machine PS40E5ASE manufactured by Nissei Plastic Industry Co., Ltd. to obtain a size of 40 mm (short side)×60 mm (long and short side)×thickness (maximum thickness portion D1 = 3 mm, Minimum thickness part D2 = 1mm) figure 1 The molded body of the plate-shaped test piece with height difference shown. Tables 1 and 2 show the color tone of the minimum thickness portion D2 (thickness 1 mm) and maximum thickness portion D1 (thickness 3 mm) of the molded article.

[0120] Glass fiber: Glass fiber PF70E-001 of Nitto Bosho Co., Ltd. with a number average fiber diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com