Buckwheat and waxy wheat liquid nutrient enhanced yellow wine and brewing method thereof

A nutrient-enhanced, glutinous wheat technology, which is applied in the fields of food processing and alcoholic beverages, can solve the problems of long solid-state fermentation production cycle, complex and cumbersome production process, and inconvenient mechanized production, so as to save rice soaking and steaming steps and reduce costs The effect of consumption and shortening the fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Threshing

[0040] The outermost hard husk of good-quality tartary buckwheat is removed, and the seed coat and grain components inside the husk are retained.

[0041] Step 2. Crush

[0042] The tartary buckwheat threshed in step 1 and high-quality waxy wheat are uniformly mixed according to the ratio of tartary buckwheat: waxy wheat (W / W) = 75%: 25%, put into a grinder and pulverize into 30-35 mesh whole powder.

[0043] Step 3. Liquefaction

[0044] During the liquefaction process, add water at 75°C to 78°C that is 1.9-2.0 times the weight of raw materials, and add α-amylase to make the enzyme concentration 18U / g, heat up to keep the temperature of the liquefaction system at 75°C to 78°C , so that the fine powder of raw materials is evenly dispersed in water.

[0045] Step 4, the first saccharification

[0046] Heat the liquefied raw materials until the temperature rises to 96°C, add high-temperature α-amylase at 90-95°C, make the concentration of high-temp...

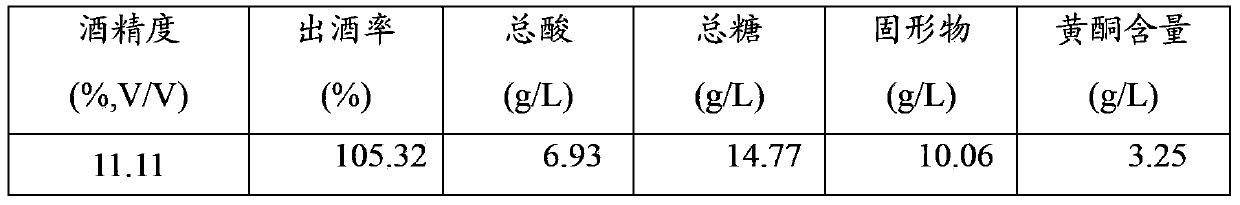

Embodiment 2

[0062] Using the method of the present invention to brew liquid nutritionally fortified yellow rice wine, the same parts as in Example 1 will not be repeated, and the difference lies in the ratio of raw materials in the step 2 pulverization process.

[0063] Threshed tartary buckwheat and high-quality waxy wheat are evenly mixed according to the ratio of tartary buckwheat: waxy wheat (W / W) = 50%: 50%, and then put into a grinder to grind into 30-35 mesh whole powder.

[0064] See Table 2 for the related indicators of the rice wine finished wine prepared according to the method of Example 2.

[0065] The yellow rice wine finished wine relevant index of table 2 embodiment 2

[0066]

[0067] Note: The alcohol yield is the ratio of rice wine with an alcohol content of 15%vol to the weight of raw materials

[0068] The finished rice wine obtained is clear and transparent, deep yellow in color, rich in aroma, mellow and refreshing in taste, and its relevant indicators have reac...

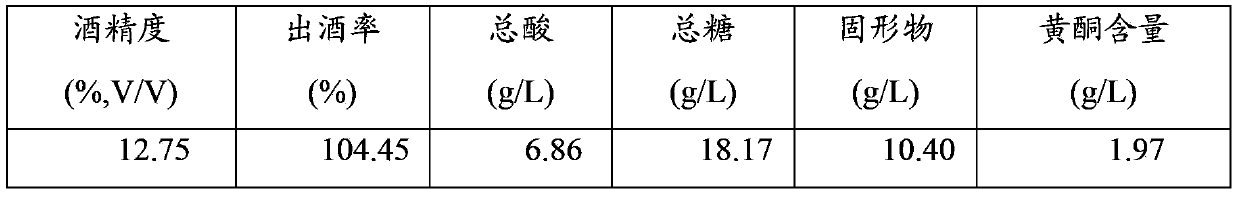

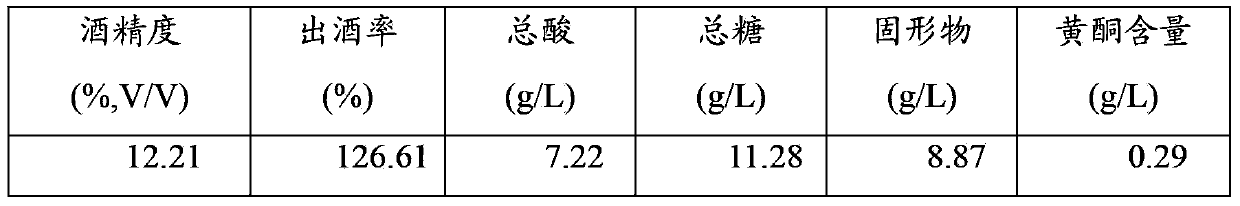

Embodiment 3

[0070] Using the method of the present invention to brew liquid nutritionally fortified yellow rice wine, the same parts as in Example 1 will not be repeated, and the difference lies in the ratio of raw materials in the step 2 pulverization process.

[0071] Threshed tartary buckwheat and high-quality waxy wheat are uniformly mixed according to the ratio of tartary buckwheat: waxy wheat (W / W) = 25%: 75%, and then put into a grinder to grind into 30-35 mesh whole powder.

[0072] See Table 3 for relevant indicators of the rice wine finished wine prepared according to the method of Example 3.

[0073] The rice wine finished wine related index of table 3 embodiment 3

[0074]

[0075] Note: The alcohol yield is the ratio of rice wine with an alcohol content of 15%vol to the weight of raw materials

[0076] The finished rice wine obtained is clear and transparent, deep yellow in color, rich in aroma, mellow and refreshing in taste, and its relevant indicators have reached the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com