Energy-saving environmental-friendly heavy oil additive with maintenance effects

An energy-saving and environmentally friendly additive technology, applied in the petrochemical field, can solve the problems of unsatisfactory combustion improvement, poor stability of emulsified oil, and high requirements for operation and maintenance, and achieve the effects of improving fuel combustion, reducing corrosion, and reducing heavy oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

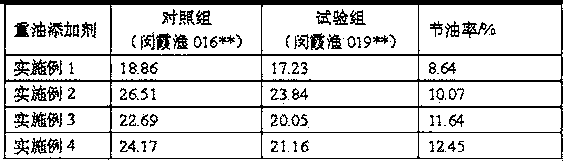

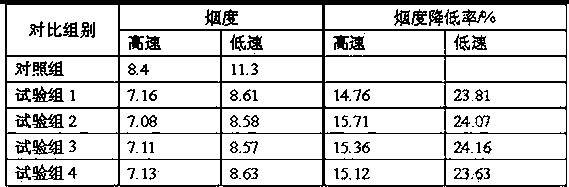

Embodiment 1

[0021] Embodiment 1, energy saving and environmental protection maintenance heavy oil additive, its effective raw material and weight ratio are: 2 parts of tricresyl phosphate, 0.3 part of methylparaben, 25 parts of calcium petroleum sulfonate, 30 parts of xylene, polyisobutylene dibutyl 15 parts of diimide and 10 parts of castor oil polyoxyethylene ether.

Embodiment 2

[0022] Embodiment 2, energy saving and environmental protection maintenance heavy oil additive, its effective raw material and weight ratio are: 3 parts of tricresyl phosphate, 0.4 part of methyl paraben, 20 parts of calcium petroleum sulfonate, 35 parts of xylene, polyisobutylene dibutyl 13 parts of diimide and 11 parts of castor oil polyoxyethylene ether.

Embodiment 3

[0023] Embodiment 3, energy saving and environmental protection maintenance heavy oil additive, its effective raw material and weight ratio are: tricresyl phosphate 4 parts, methylparaben 0.4 part, petroleum calcium sulfonate 18 parts, xylene 35 parts, polyisobutylene dibutyl 10 parts of diimide and 15 parts of castor oil polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com