Preparation method of porous hollow micro-cube blocky tin dioxide

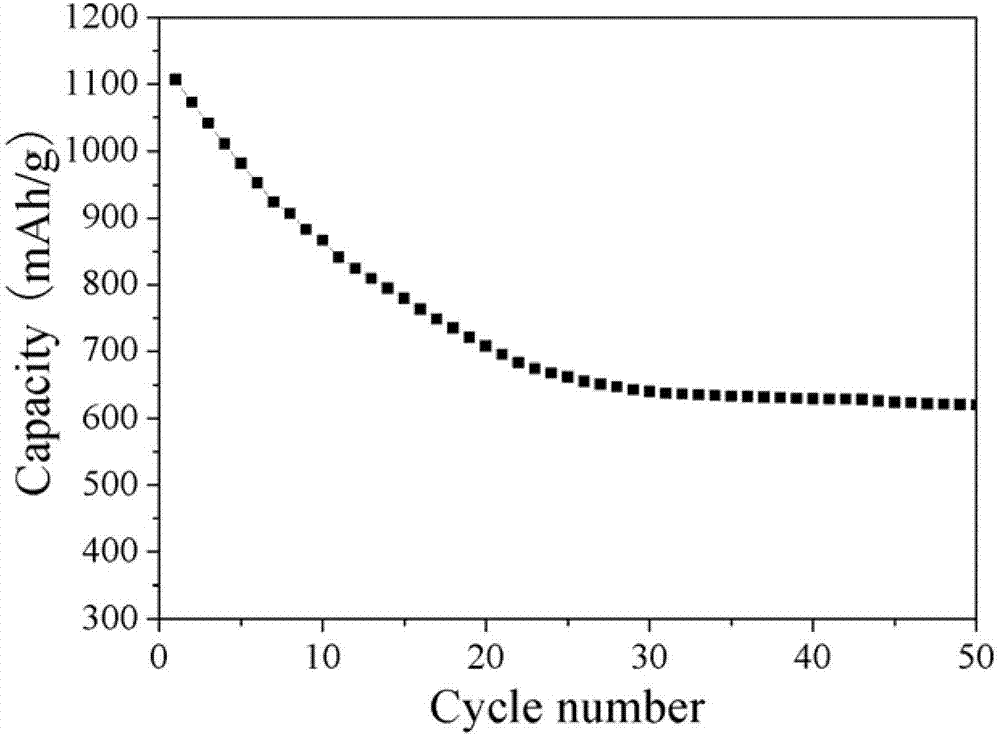

A tin dioxide and cubic technology is applied in the field of preparation of porous hollow micro-cube-shaped tin dioxide, which can solve the problem that the control of tin dioxide nanocrystals cannot be realized, the structure pulverization cannot be well solved, and the cycle performance is not good. and other problems, to achieve the effect of solving the problem of structure pulverization, large specific capacity and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

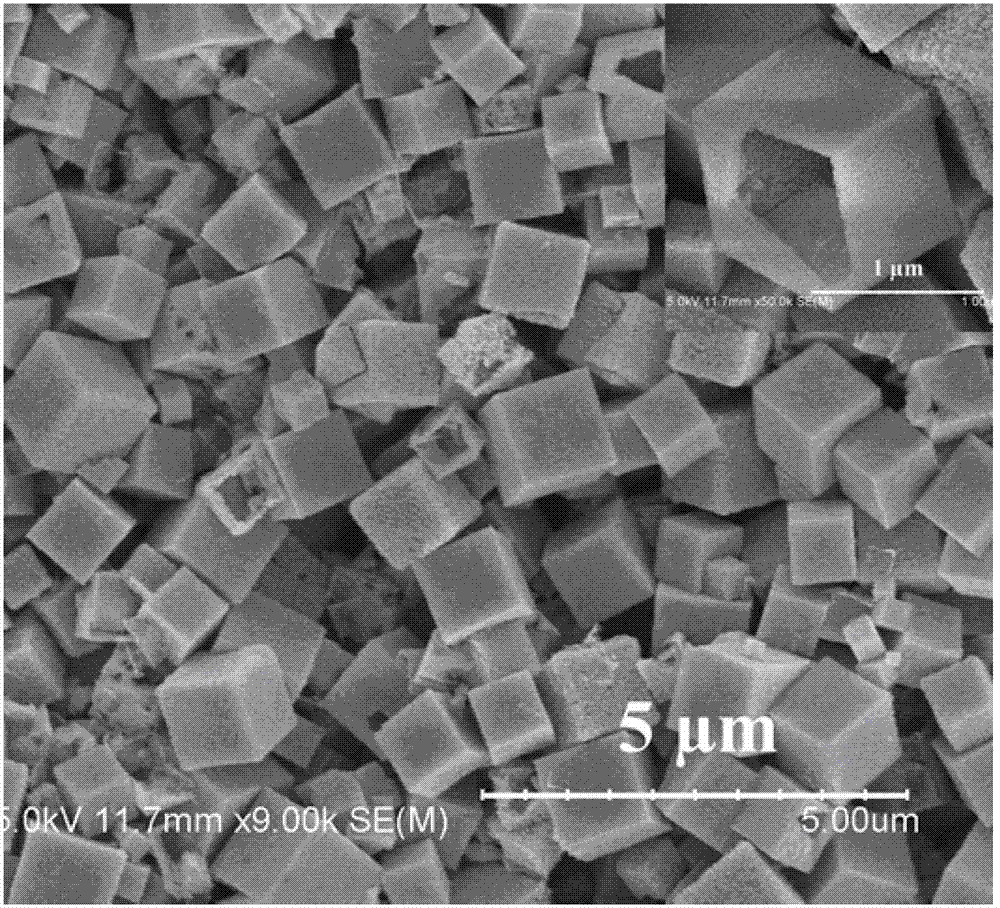

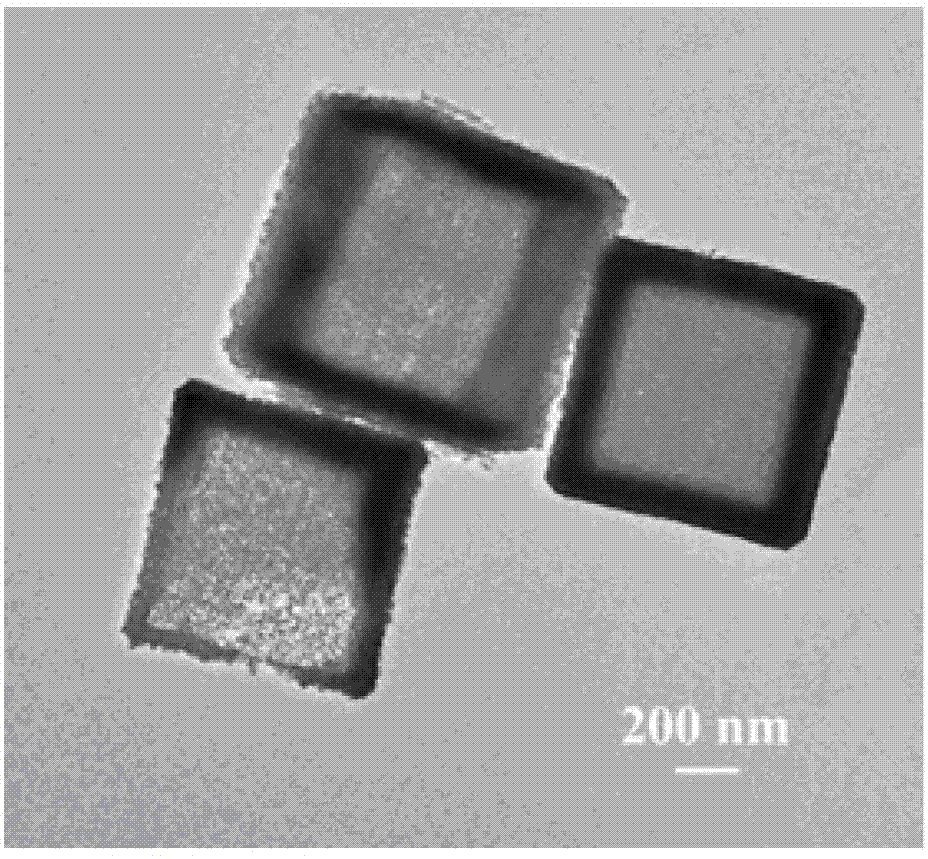

[0029] A preparation method of porous hollow micron cubic tin dioxide powder, the steps comprising:

[0030] A, mixing process: dissolving tin tetrachloride pentahydrate in water, then adjusting the pH of the solution to 12.5 with 5.0mol / L sodium hydroxide, preparing 30 milliliters of 0.0005mol / L sodium stannate solution; dissolving cobalt chloride Prepare 15 ml of 0.001mol / L cobalt chloride solution in water; mix the above-mentioned solutions and heat in a water bath at 60°C for 40 minutes, stir to obtain a cloudy solution; place the obtained cloudy solution at 25°C for aging After 12 hours, the precipitate was filtered, washed, and dried to obtain a solid cobalt hydroxystannate precursor in the form of micron cubes;

[0031] The stirring uses magnetic stirring, and the rotating speed is 15 rpm;

[0032] B. Conversion process: transform the precursor powder obtained in step A with 3 mol / L sodium hydroxide solution whose mass is 200 times that of the precursor powder at 10°C ...

Embodiment 2

[0036] A preparation method of porous hollow micron cubic tin dioxide powder, the steps comprising:

[0037] A, mixing process: sodium stannate is dissolved in water, and then the pH value of the solution is adjusted to 12.5 with 5.0mol / L potassium hydroxide to obtain 30 milliliters of 0.05mol / L sodium stannate solution; cobalt nitrate is dissolved in water to prepare 15 milliliters of 0.2mol / L cobalt chloride solution were obtained; the above-mentioned solution was mixed and heated in a water bath at 50°C for 80 minutes, and stirred to obtain a cloudy solution; the obtained cloudy solution was allowed to stand and age at 30°C for 4 hours, and then The precipitate is filtered, washed, and dried to obtain a solid micron cubic cobalt hydroxystannate precursor;

[0038] The stirring uses magnetic stirring, and the rotating speed is 80 rpm;

[0039] B. Transformation process: transform the precursor powder obtained in step A with a 4mol / L potassium hydroxide solution whose mass is ...

Embodiment 3

[0043] A preparation method of porous hollow micron cubic tin dioxide powder, the steps comprising:

[0044] A. Mixing process: Dissolve sodium stannate in water, then adjust the pH of the solution to 13.5 with 5.0mol / L sodium hydroxide to obtain 30 milliliters of 0.5 mol / L sodium stannate solution; dissolve cobalt chloride in water to prepare 15 milliliters of 1mol / L cobalt chloride solution were obtained; the above-mentioned solution was mixed and heated in a water bath at 60° C. for 50 minutes, and stirred to obtain a cloudy solution; the obtained cloudy solution was left to age at 80° C. for 6 hours, and then The precipitate is filtered, washed, and dried to obtain a solid micron cubic cobalt hydroxystannate precursor;

[0045] The stirring uses magnetic stirring, and the rotating speed is 50 rpm;

[0046] B. Conversion process: convert the precursor powder obtained in step A with a 5 mol / L sodium hydroxide solution whose mass is 100 times that of the precursor powder at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com