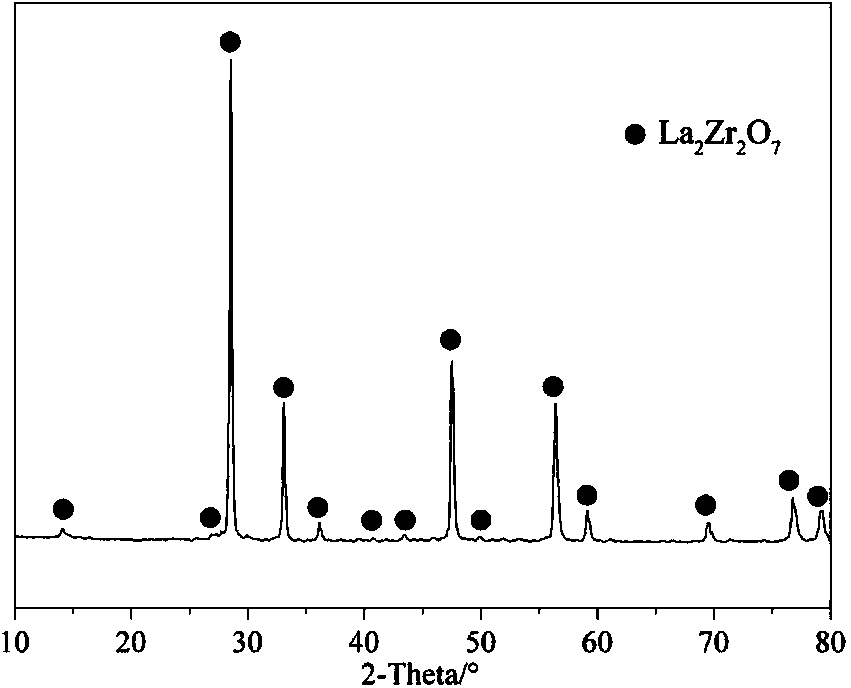

Preparation method of single-phase pyrochlore-type La2Zr2O7 nano-powder

A technology of nano-powder and pyrochlore, which is applied in the field of preparing single-phase pyrochlore-type La2Zr2O7 nano-powder, which can solve the problems of easy sintering, high crystallinity, and good dispersion, and achieve no corrosion of equipment and good crystallinity , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of single-phase pyrochlore type La prepared by the present invention 2 Zr 2 o 7 Nano powder mainly has the following steps:

[0029] (1) Molar ratio of ZrOCl 2 ·8H 2 O:H 2 O:CH 3 OH=1:5:10, 5.00g ZrOCl 2 ·8H 2 O was slowly added to the mixed solution of 1.40g water and 4.97g methanol, and kept stirring to obtain a transparent solution A liquid; at the same time, by molar ratio La(NO 3 ) 3 ·6H 2 O:H 2 O:CH 3 OH=1:0.5:10, 6.66g La(NO 3 ) 3 ·6H 2 O slowly add 0.14g of water and 4.97g of methanol in the mixed solution, stirring constantly, to obtain a transparent solution B liquid;

[0030] (2) Mix liquid A and liquid B to obtain a transparent mixed solution, and stir evenly;

[0031] (3) Under the condition of continuous stirring, add molar ratio: citric acid: Zr to the mixed solution in sequence 4+ =0.1:1 Add 0.33g of citric acid, polyethylene glycol by mass ratio: Zr 4+ =1:1 Add polyethylene glycol 1.41g, wherein, the number average molecular wei...

Embodiment 2

[0036] A kind of single-phase pyrochlore type La prepared by the present invention 2 Zr 2 o 7 Nano powder mainly has the following steps:

[0037] (1) Molar ratio of ZrOCl 2 ·8H 2 O:H 2 O:C 3 h 7 OH=1:8:10, 5.00g ZrOCl 2 ·8H 2 O was slowly added to the mixed solution of 2.24g water and 9.31g propanol, and kept stirring to obtain a transparent solution A; meanwhile, La(NO 3 ) 3 ·6H 2 O:H 2 O:C 3 h 7 OH=1:2:10, 6.66g La(NO 3 ) 3 ·6H 2 O slowly add 0.56g water and 9.31g propanol in the mixed solution, stir constantly, obtain transparent solution B liquid;

[0038] (2) Mix liquid A and liquid B to obtain a transparent mixed solution, and stir evenly;

[0039] (3) Under the condition of continuous stirring, add molar ratio: citric acid: Zr to the mixed solution in sequence 4+ =0.4:1 Add 1.32g of citric acid, polyethylene glycol by mass ratio: Zr 4+ =1:7.5 adds Polyethylene Glycol 0.19g, wherein, the number average molecular weight of Polyethylene Glycol is 20000...

Embodiment 3

[0044] A kind of single-phase pyrochlore type La prepared by the present invention 2 Zr 2 o 7 Nano powder mainly has the following steps:

[0045] (1) Molar ratio of ZrOCl 2 ·8H 2 O: H 2 O: C 2 h 5 OH=1:6:10, 5.00g ZrOCl 2 ·8H 2 O was slowly added to the mixed solution of 1.68g water and 7.14g ethanol, and kept stirring to obtain a transparent solution A; meanwhile, La(NO 3 ) 3 ·6H 2 O: H 2 O: C 2 h 5 OH=1:1:10, 6.66g La(NO 3 ) 3 ·6H 2 O slowly add 0.28g water and 7.14g ethanol in the mixed solution, stir constantly, obtain transparent solution B liquid;

[0046] (2) Mix liquid A and liquid B to obtain a transparent mixed solution, and stir evenly;

[0047] (3) Under the condition of continuous stirring, add molar ratio: citric acid: Zr to the mixed solution in sequence 4+ =0.2:1 Add citric acid 0.65g, polyethylene glycol by mass ratio: Zr 4+ =1:5 adds polyethylene glycol 0.28g, wherein, the number average molecular weight of polyethylene glycol is 20000, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com