Environment-friendly high-wear-resistance lubricating oil and preparation method thereof

An environmentally friendly, high anti-wear technology, applied in the direction of lubricating compositions, petroleum industry, additives, etc., can solve the problems of lack of biodegradability, etc., achieve the effects of reducing the friction coefficient, increasing the service life of machinery, and reducing the emission of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

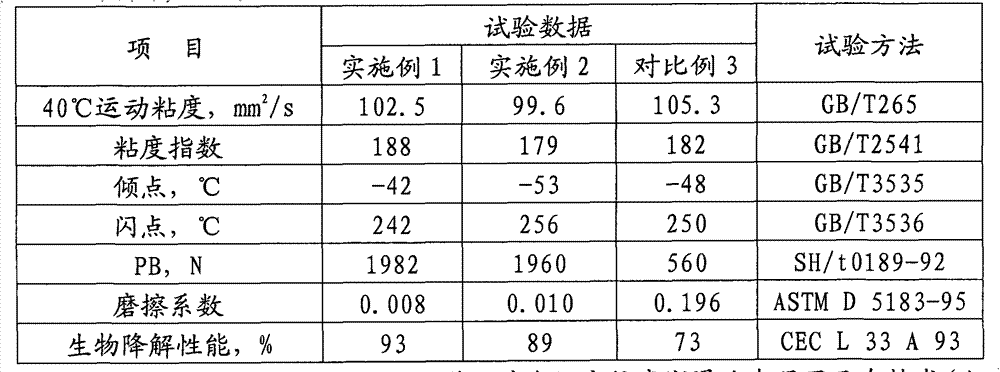

Embodiment 1

[0032] 1. Preparation of N-oleoylserine: Weigh 2.82g (0.01mol) of oleic acid and PCl 3 2.06g was placed in a dry three-neck flask equipped with a reflux condenser, heated to reflux for 4h, and the excess PCl was evaporated 3 , Distilled under reduced pressure to obtain oleoyl chloride. React oleoyl chloride with 1.05g of serine in an alkaline solution of pH 8-10 at 15-20°C for 4-5 hours. After the reaction, let it stand for cooling, acidify the reaction liquid with hydrochloric acid to pH 1-2, wash the oil layer with water and petroleum ether, and dry it to obtain N-oleoylserine.

[0033] 2.C 60Preparation of N-oleoylserine derivatives: Weigh 720mgC 60 Add it into 150ml of xylene, ultrasonically disperse for 1.5h, add 2g of N-oleoylserine, fill with nitrogen, react at 120°C for 8h, filter and wash four times with absolute ethanol, and dry under vacuum at 60°C to obtain C 60 N-oleoylserine derivatives.

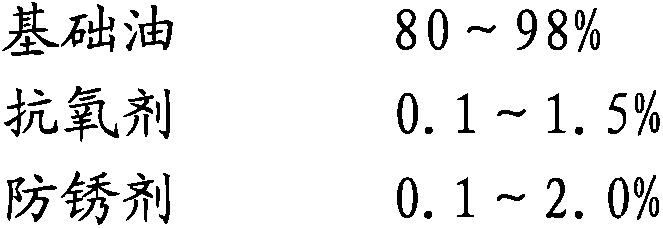

[0034] 3. Preparation of environment-friendly high anti-wear lubricat...

Embodiment 2

[0036] Steps 1 and 2 are the same as above. Take 10g of sulfurized castor oil, 75g of trimethylolpropane ester, and a viscosity of 2mm at 100°C 2 / sPA0 11g in a three-necked flask, stirred and heated to 65°C for 1h, added 0.5g of methylene bisphenol antioxidant, 1.0g of low-basic calcium sulfonate rust inhibitor with a base value of 60mg KOH / g, continued to stir for 2h, and then Add the C prepared above 60 N-oleoylserine derivative 2.5g, ultrasonic dispersion 2h, the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com