Lignin modified cationic waterborne polyurethane (WPU) adhesive and preparation method thereof

A water-based polyurethane and lignin technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of lignin modified cationic waterborne polyurethane of the present invention comprises as follows:

[0029] Step 1: reacting the polymer diol with trimethylolpropane, and then reacting with polyisocyanate to obtain the first intermediate;

[0030] Step 2: reacting the first intermediate obtained in step 1 with a dihydroxy compound containing an amino group to obtain a second intermediate;

[0031] Step 3: react lignin and small molecule chain extender with the second intermediate obtained in step 2 to obtain lignin-modified cationic waterborne polyurethane.

[0032] In the first step, the polymer diol is first reacted with trimethylolpropane, the reaction temperature is preferably 110-120°C, the reaction time is preferably 1-2h, and the polymer diol is preferably Polybutylene adipate, polypropylene glycol or polycarbonate diol, more preferably polybutylene adipate, polypropylene glycol or polycarbonate with a molecular weight of 1000-5000 Daltons...

Embodiment 1

[0048] Add 1000g polybutylene adipate (molecular weight: 1000 Daltons) and 132g trimethylolpropane into the three-necked flask, raise the temperature to 110°C, depressurize for 1 hour, cool down to 85°C under nitrogen protection, and add 120ml of Butanone, drop 710g of 2,4-toluene diisocyanate, after the dropwise addition, react for 3.5 hours to obtain the first intermediate;

[0049] Add 80ml of butanone to the first intermediate, cool down to room temperature, and dropwise add 65g of N-methyldiethanolamine hydrophilic chain extender at a rate of 3ml / min. After the addition, react for 0.5 hours to obtain the second Intermediate;

[0050] Add 150ml of butanone to the second intermediate, add 86g of lignin and 106g of ethylene glycol, heat up to 90°C, react for 2 hours, add 1650ml of deionized water, then add 86g of concentrated hydrochloric acid, stir for 0.5 hours, reduce Butanone is removed under pressure to obtain lignin-modified cationic waterborne polyurethane.

Embodiment 2

[0052] Add 5000g of polybutylene adipate (molecular weight: 5000 Daltons) and 158g of trimethylolpropane into the three-neck flask, raise the temperature to 110°C, depressurize for 1 hour, cool down to 85°C under nitrogen protection, and add 180ml Butanone, dropwise added 960g of diphenylmethane-4,4'-diisocyanate, after the dropwise addition, reacted for 5 hours to obtain the first intermediate;

[0053] Add 160ml of butanone to the first intermediate, cool the temperature to room temperature, and drop 89g of N-(3-aminopropyl)diethanolamine hydrophilic chain extender at a rate of 5ml / min. After adding, react 1 hour, obtain the second intermediate;

[0054] Add 380ml of butanone to the second intermediate, add 158g of lignin and 185g of diethylene glycol, heat up to 90°C, react for 3 hours, add 2230ml of deionized water, then add 138g of concentrated hydrochloric acid, stir for 1 hour, reduce Butanone is removed under pressure to obtain lignin-modified cationic waterborne poly...

PUM

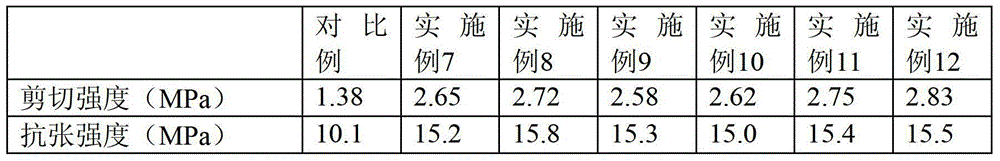

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com