Electrolyte for lithium ion battery using silica-based material as negative electrode material and lithium ion battery

A technology of lithium-ion batteries and silicon-based materials, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor conductivity, low charge-discharge efficiency, and poor cycle performance of lithium-ion batteries, so as to improve life and charge Discharge efficiency and cycle performance, the effect of not easy to decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

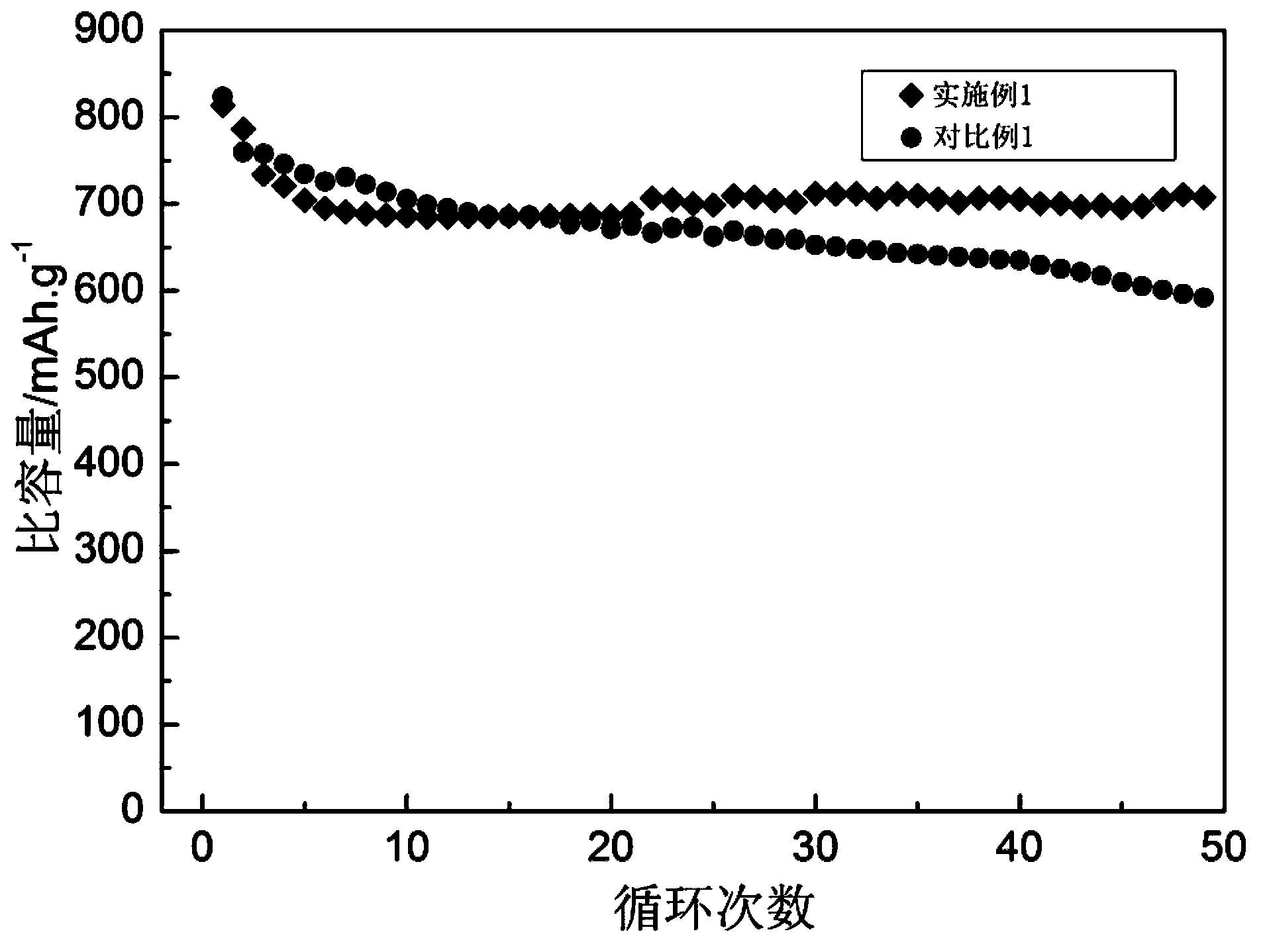

Embodiment 1

[0018] This embodiment provides a kind of lithium-ion battery electrolyte solution using silicon-carbon composite material as the negative electrode material, including: lithium salt LiPF 6 , non-aqueous organic solvents EC, DEC and FEC (the mass ratio of EC, DEC and FEC is EC:DEC:FEC=6:3:1), film-forming additives VC and TPFPB. Among them, LiPF 6 The concentration of VC is 1M, the content of VC is 2% of the total weight of the electrolyte, and the content of TPFPB is 5% of the total weight of the electrolyte.

[0019] The preparation method of the electrolyte is as follows: the lithium salt LiPF 6 Soluble in the mixed solvent of non-aqueous organic solvents EC, DEC and FEC, wherein the mass ratio of EC, DEC and FEC is EC:DEC:FEC=6:3:1, LiPF 6 The concentration is 1M; then add the film-forming additive VC to the solution, and then add the film-forming additive TPFPB to obtain the electrolyte. Wherein, the content of VC is 2% of the total weight of the electrolyte, and the c...

Embodiment 2

[0036] This embodiment provides a kind of electrolyte solution for lithium-ion battery with silicon material as the negative electrode material, including: lithium salt LiClO 4 , non-aqueous organic solvents EC, DEC and DMC (the mass ratio of EC, DEC and DMC is EC:DEC:DMC=4:4:2), film-forming additives VC and TPFPB. Among them, LiClO 4 The concentration is 0.5M, the content of VC is 2% of the total weight of the electrolyte, and the content of TPFPB is 2% of the total weight of the electrolyte.

[0037] The preparation method of the electrolyte is as follows: Lithium salt LiClO 4 Soluble in a mixed solvent of non-aqueous organic solvents EC, DEC and DMC, wherein the mass ratio of EC, DEC and DMC is EC:DEC:DMC=4:4:2, LiClO 4 The concentration is 0.5M; then add the film-forming additive VC to the solution, and then add the film-forming additive TPFPB to obtain the electrolyte. Wherein, the content of VC is 2% of the total weight of the electrolyte, and the content of TPFPB is...

Embodiment 3

[0041] This embodiment provides a kind of lithium-ion battery electrolyte solution using silicon-copper alloy material as the negative electrode material, including: lithium salt LiPF 6 and LiClO 4 , non-aqueous organic solvents EC, EMC and DMC (the mass ratio of EC, EMC and DMC is EC:EMC:DMC=4:3:3), film-forming additives VC, VEC and TPFPB. Among them, LiPF 6 At a concentration of 0.6M, LiClO 4 The concentration is 0.4M, the content of VC is 2% of the total weight of the electrolyte, the content of VEC is 1% of the total weight of the electrolyte, and the content of TPFPB is 4% of the total weight of the electrolyte.

[0042] The preparation method of the electrolyte is as follows: the lithium salt LiPF 6 and LiClO 4 Soluble in a mixed solvent of non-aqueous organic solvents EC, EMC and DMC, wherein the mass ratio of EC, EMC and DMC is EC:EMC:DMC=4:3:3, LiPF 6 At a concentration of 0.6M, LiClO 4 The concentration is 0.4M; then add film-forming additive VC to this soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com