Oxidized graphene-rhamnolipid composite material and preparation method and application thereof

A technology of rhamnolipid and composite materials, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problems of high biological toxicity, poor treatment effect, and low adsorption capacity, and achieve biological Low toxicity, easy solid-liquid separation, large adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation method of graphene oxide-rhamnolipid composite material and application of methylene blue dye adsorption.

[0036] (1) Preparation of graphene oxide-rhamnolipid composite material: Weigh 100 mg of graphene oxide and add it to 100 ml of dimethylformamide, ultrasonically strip it for 1 hour to form graphene oxide mixture, and then add graphene oxide mixture to Add 400mg rhamnolipid with a mass content of 90%, 400mg EDC and 80mg DMAP and mix evenly. After ultrasonic reaction at 25°C-45°C for 3h, add 50ml of anhydrous methanol and stir for 15min to produce precipitation; After washing with water and ethanol, centrifuge at 10,000 rpm for 15 minutes, wash and filter with deionized water, and finally vacuum freeze-dry at -110°C for 3 days to obtain the graphene oxide-rhamnolipid composite material.

[0037] (2) Application of graphene oxide-rhamnolipid composite material for adsorption of methylene blue dye: Weigh 10 mg of graphene oxide-rhamnolipid composite mater...

Embodiment 2

[0040] Preparation method of graphene oxide-rhamnolipid composite material and application of methylene blue dye adsorption.

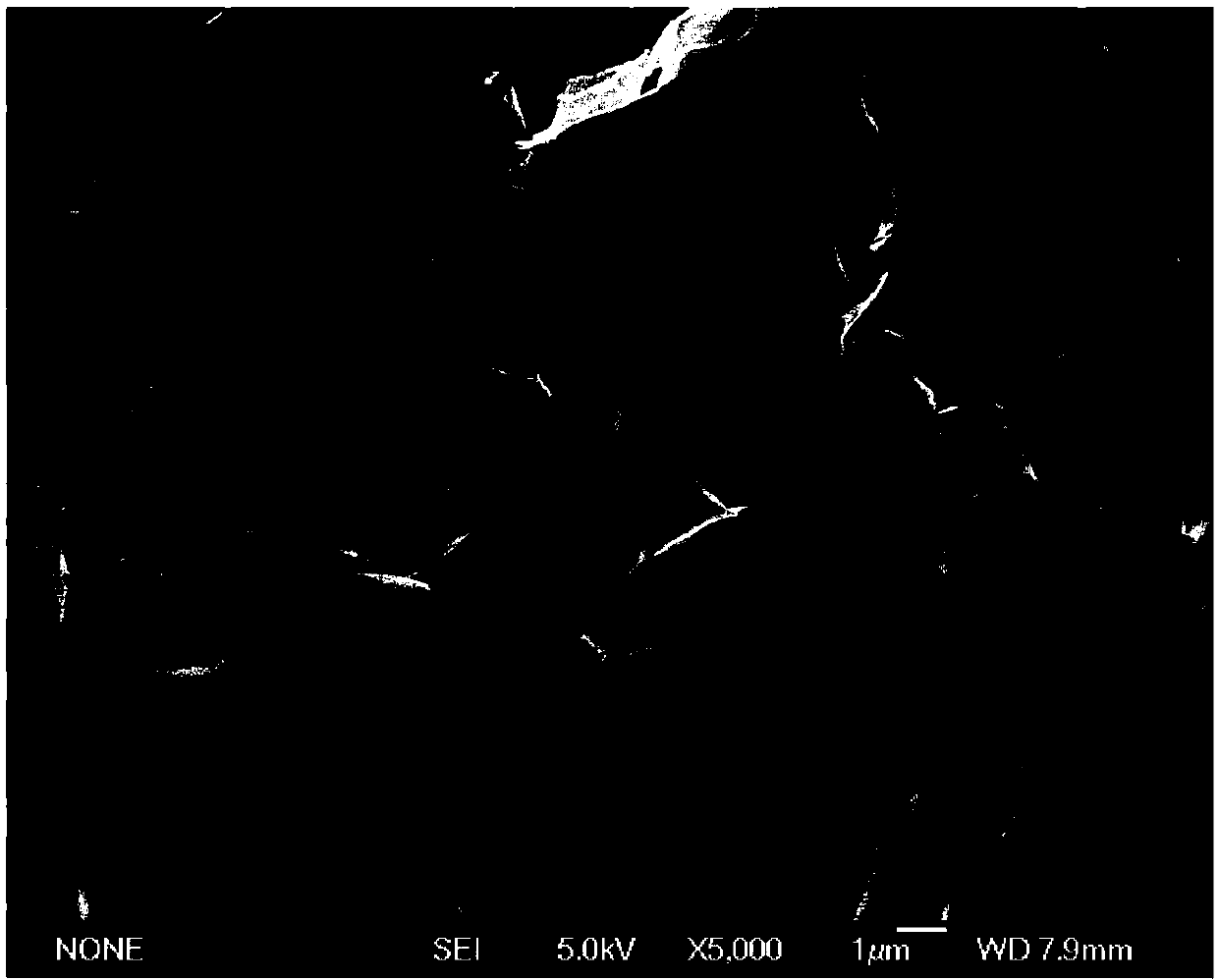

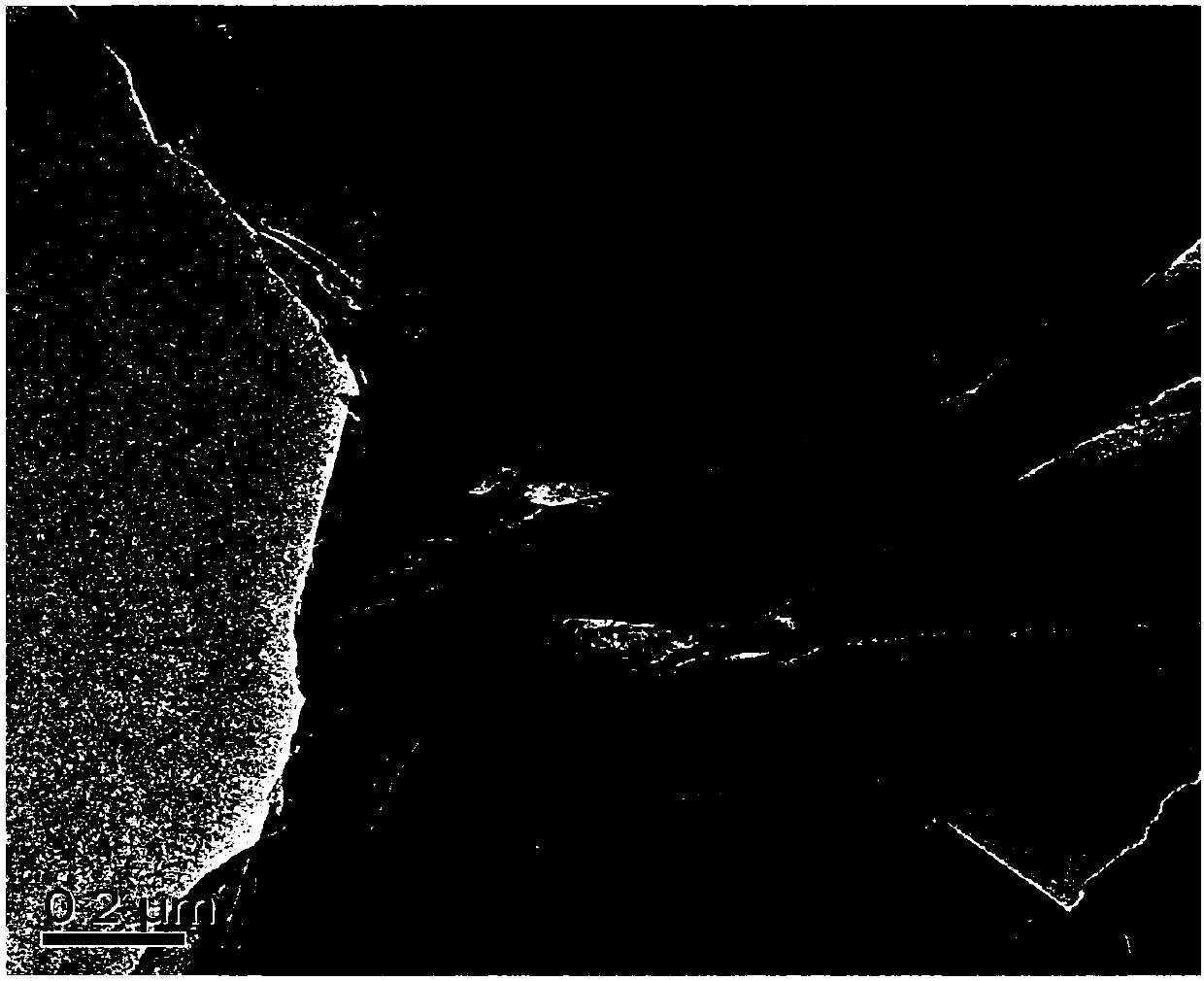

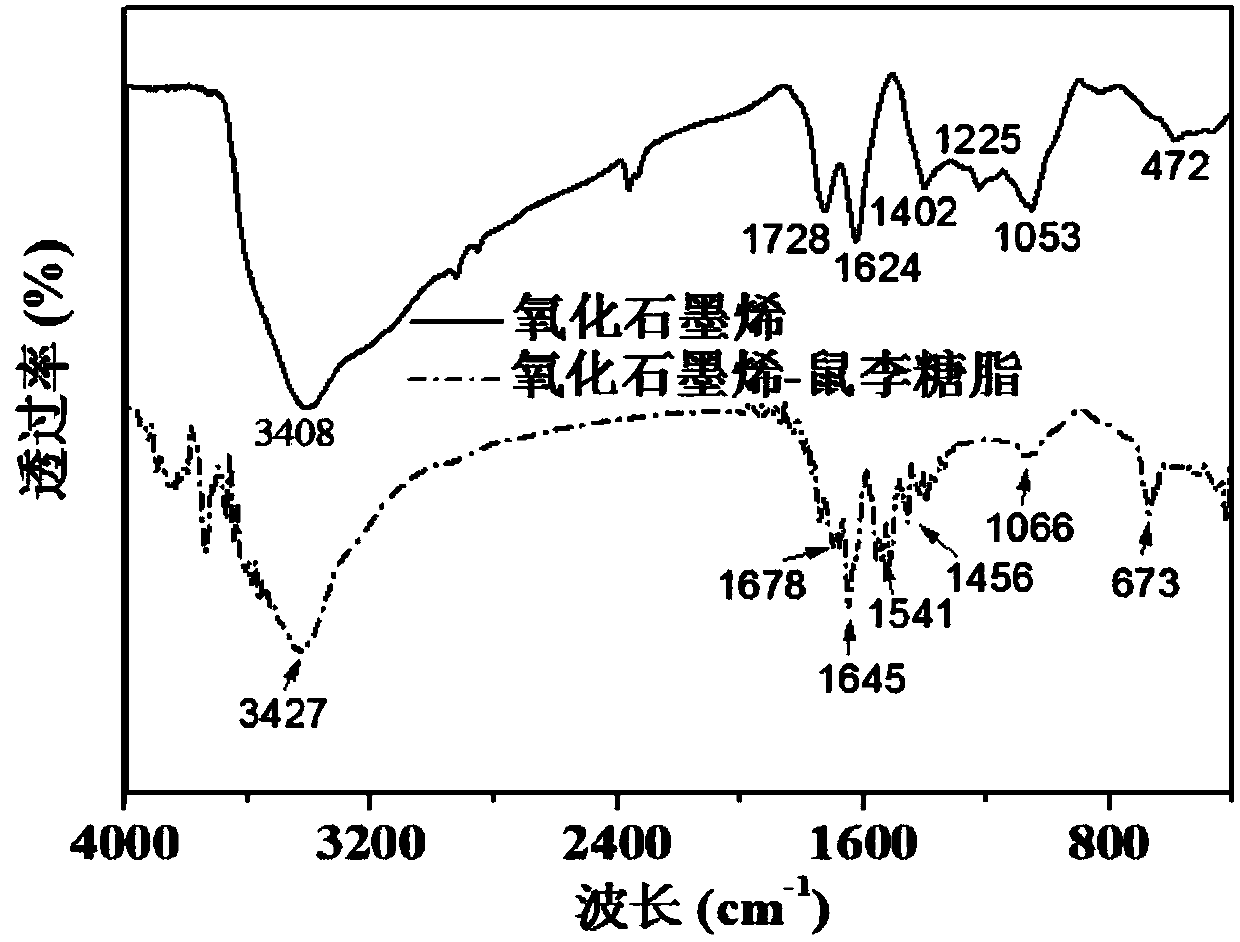

[0041](1) Preparation of graphene oxide-rhamnolipid composite material: Weigh 100 mg of graphene oxide and add it to 100 ml of dimethylformamide, ultrasonically strip it for 1 hour to form graphene oxide mixture, and then add graphene oxide mixture to Add 300mg rhamnolipid with a mass content of 90%, 500mg EDC and 100mg DMAP and mix evenly. After ultrasonic reaction at 25°C-45°C for 3h, add 60ml of anhydrous methanol and stir for 15min to produce precipitation; After washing with water and ethanol, centrifuge at 10,000 rpm for 15 minutes, wash and filter with deionized water, and finally vacuum freeze-dry at -110°C for 2 days to obtain graphene oxide-rhamnolipid composite material. The graphene oxide-rhamnolipid composite material that above-mentioned steps makes is carried out scanning electron microscope, transmission electron microscope and Fourier ...

Embodiment 3

[0046] Preparation method of graphene oxide-rhamnolipid composite material and application of adsorbed methyl violet dye.

[0047] (1) Preparation of graphene oxide-rhamnolipid composite material: Weigh 100 mg of graphene oxide and add it to 100 ml of dimethylformamide, ultrasonically strip it for 1 hour to form graphene oxide mixture, and then add graphene oxide mixture to Add 200mg rhamnolipid with a mass content of 90%, 600mg EDC and 100mg DMAP and mix evenly. After ultrasonic reaction at 25℃~45℃ for 3h, add 50ml anhydrous methanol and stir for 15min to produce precipitation; After washing with water and ethanol, centrifuge at 10,000 rpm for 15 minutes, wash and filter with deionized water, and finally vacuum freeze-dry at -110°C for 3 days to obtain the graphene oxide-rhamnolipid composite material.

[0048] (2) Adsorption of methyl violet by graphene oxide-rhamnolipid composite material: Weigh 5mg, 10mg, 15mg, 20mg graphene oxide-rhamnolipid composite material in 25ml, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com