Organic functional luminescent carbon quantum dots, preparation method therefor and applications thereof

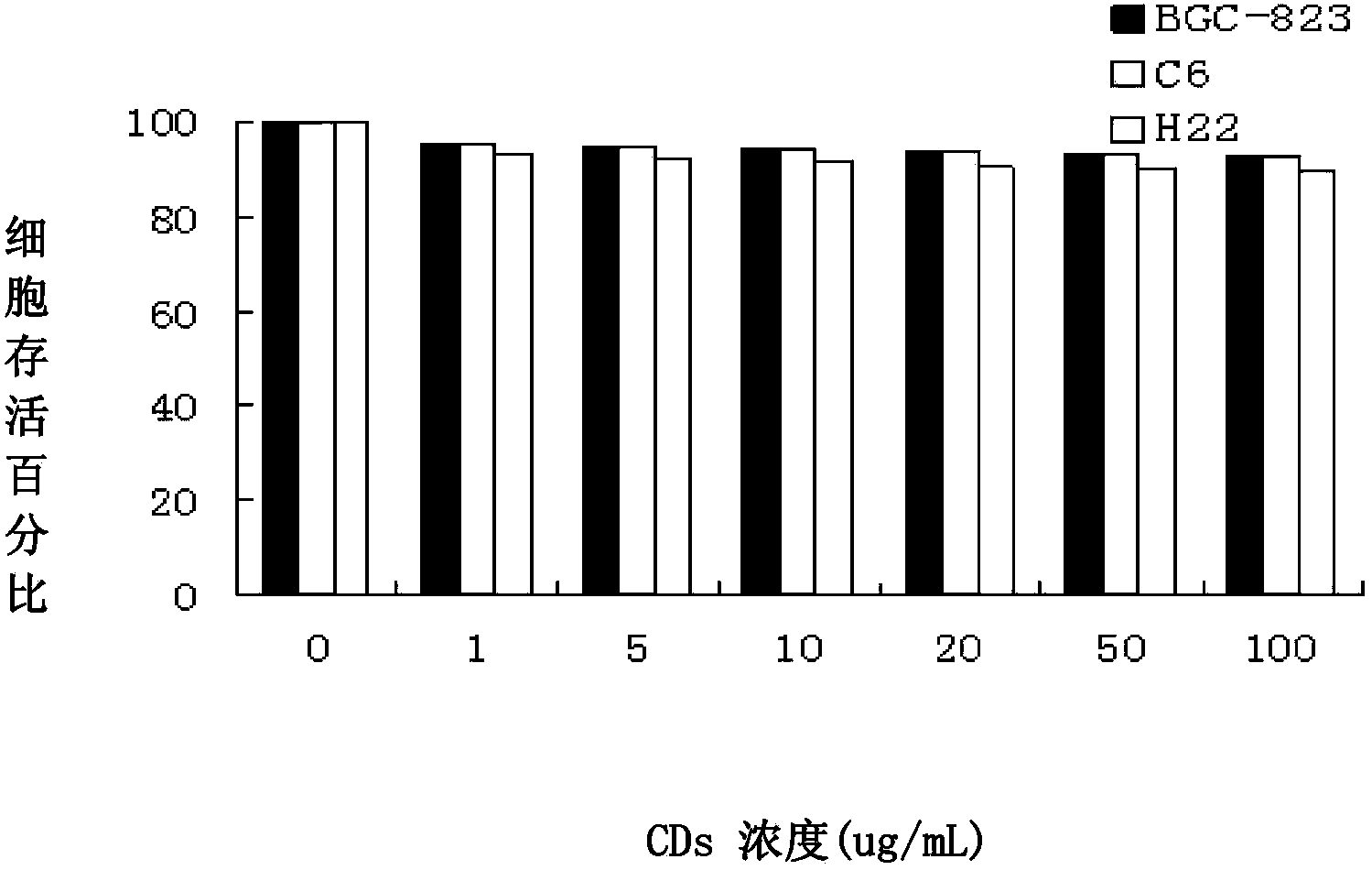

A technology of carbon quantum dots and functionalization, which is applied in the field of preparation of luminescent carbon quantum dots, can solve the problems of complex process synthesis conditions, low luminescent quantum yield, difficulty in realizing relatively independent control of quantum dot size structure and surface properties, and achieve The effect of simple preparation process and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Preparation of organic functionalized luminescent carbon quantum dots SCQD 1: at room temperature, add 10 ml of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (AEAPMS) in a 100ml three-necked flask, degas with nitrogen 5 minutes; under nitrogen flow and stirring, the temperature was raised to 270 ° C, 0.1 g of lactic acid was quickly added to the system, and kept at this temperature for 1 minute, the product obtained was naturally cooled to room temperature, recrystallized and column separated (n-hexane: di Chloromethane (volume ratio of 2:1) was purified to obtain organic functionalized luminescent carbon quantum dots SCQD1 with high luminous efficiency.

[0062] The organic functionalized luminescent carbon quantum dot has N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane on the surface of the carbon quantum dot.

[0063] Elemental analysis found values: C, 45.81; H, 8.87; N, 13.65. Infrared spectra and 13 The C-NMR nuclear magnetic spectrum is Figure 5 and Figure ...

Embodiment 2

[0068] Preparation of organic functionalized luminescent carbon quantum dots SCQD2: at room temperature, add 50 milliliters of aminopropyltriethoxysilane to a 500ml three-necked flask, and degas with nitrogen for 15 minutes; under nitrogen and stirring, heat up to 350°C, Quickly add 8g of gluconic acid into the system, keep it at this temperature for 30 minutes, the obtained product is naturally cooled to room temperature, recrystallized and purified by column separation (the volume ratio of n-hexane:ethyl acetate is 2:1) to obtain high luminescence Efficiency of Organic Functionalized Luminescent Carbon Quantum Dots SCQD2. The surface of SCQD2 bears aminopropyltriethoxysilane with a particle size of 4.5 nm. When excited by light with a wavelength of 360 nm, SCQD2 exhibits strong blue fluorescence with a central wavelength of 450 nm in the fluorescence spectrum, a half-maximum width (FWHM) as low as 60 nm, and a luminescence quantum efficiency of 45%.

Embodiment 3

[0070] Preparation of organic functionalized luminescent carbon quantum dots SCQD3: at room temperature, add 50 milliliters of γ-glycidyl etheroxypropyltrimethoxysilane in a 500ml three-necked flask, nitrogen degassing for 15 minutes; under nitrogen and stirring, heat up To 300°C, quickly add 8g of phthalic acid into the system, keep at this temperature for 30 minutes, the product obtained is naturally cooled to room temperature, recrystallized and column separated (the volume ratio of n-hexane:ethyl acetate is 3:1 ) was purified to obtain organic functionalized luminescent carbon quantum dots SCQD3 with high luminous efficiency. The surface of SCQD3 bears aminopropyltriethoxysilane with a particle size of 1.5 nm. When excited with light in the wavelength range of 340–400 nm, SCQD3 exhibits strong blue fluorescence with a luminous quantum efficiency of 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com