Preparation technology of biodiesel produced from non refined grease

A biodiesel and preparation process technology, which is applied in the petroleum industry, biofuels, fatty acid esterification, etc., can solve the problems of low utilization rate of raw materials, poor quality, and unstable process, and achieve good quality and no waste of raw materials. , energy and resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

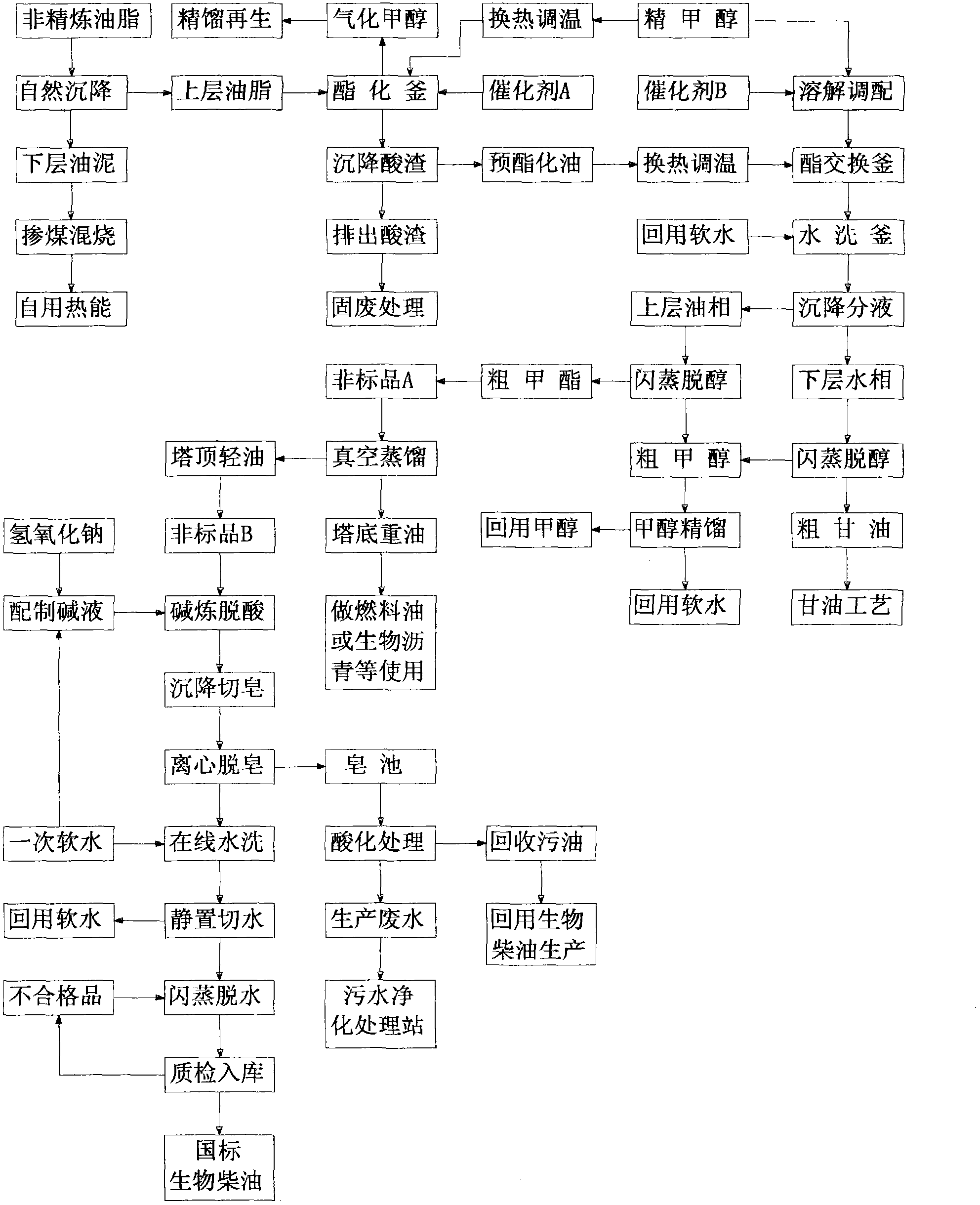

[0035] see figure 1 , the present invention uses non-refined oil as raw material through pre-esterification, transesterification and deep deacidification to produce the national standard biodiesel preparation method, that is, the preparation process of non-refined oil to produce biodiesel, which can reduce the non-refined oil according to the specific production cost And the purpose requires the production of non-standard product A, non-standard product B and biodiesel products that strictly comply with the national standard GB / T 20828-2007. The non-refined oil is put into storage, heated or naturally settled in the oil storage tank or tank, and enters the reaction Sludge, sewage, residue, etc. are fully removed before the kettle, and these impurities are mixed into coal as fuel for the production line to use heat. Its operating process is as follows:

[0036] The oil that has been removed from the impurities is introduced into the reactor, the stirring and self-circulation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com